loading

| Quantity: | |

| Place of Origin | CHINA |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-C30 |

| Minimum Order Quantity | 1SET |

| Price | negotiation |

| Packaging Details | FOAM AND CARTON |

| Delivery Time | 3DAYS |

| Payment Terms | T/T, Western Union, MoneyGram, PAYPAL |

| Supply Ability | 500 SETS PER MONTH |

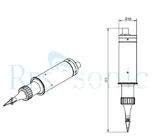

| Name | Ultrasonic Cutting Pencil | Frequency | 35Khz |

|---|---|---|---|

| Power | 500w | Type | Light Al |

| Cutting Blade | Titanium Alloy Blade | Blade | Easy Replace |

| High Light | ultrasonic cutting machine,portable ultrasonic cutter | ||

Ultrasonic Cutting Machine is a class of device using ultrasonic energy for cutting. Instead of using traditional blade cutting, ultrasonic cutting has its advantages of smooth, reliable cutting, accurate trimming, no deformation, no raising, fuzzing, spinning, wrinkling etc. It can avoid the rough cutting-edge, coked edge, fuzzballs and other shortcomings of laser cutting machine.

Ultrasonic cutting machine is used for cutting rubber, synthetic fabric, cloth, plastic, sheet metal, food etc.

The cutting of food products using ultrasound is performed when an ultrasonic blade comes into contact with the product to be cut, the high vibration of 40,000 pulses per second, makes this product very easily be cut even if it is of delicate or sticky texture composition. The much higher vibration does not allow any product to stick to the blade. The cut is clean and without pressure on the product.

This Ultrasonic Cutter is designed compact and lightweight with an easy hand grip to reduce fatigue allowing for long continuous operation. This ideal NSK handpiece offers excellent maneuverability with no vibration to the hand ensuring an accurate and sharp cutting finish. The controller automatically adjusts the output power depending on the load so there is no need to make any adjustments on the controller during the working process. A constant frequency provides steady cutting results. From simple work to fine cutting and complicated shapes, this Ultrasonic cutting Knife performs effortlessly and beautifully.

Ultrasonic Cutters are small in size and do not require large installation areas. Special equipment is not required for the installation. Ultrasonic Cutters are small enough to be hand-held for many operations.

Ultrasonic Cutters can also be attached to automated machinery arms. Although they may not be familiar to you, they play an active role in the manufacturing processes of various industrial products which we use daily.cutt-welding of thermoplastic or thermoplastic coated fabrics and fleeces. Thereby two layers one obove the other are cut and the edges are welded together at the same time.

An even more compact and powerful high frequency ultrasonic cutter than previous models results in a sharper cut. User-friendly design fully utilizes the robot’s operation area. A forced cooling system with air inlet enables extended continuous use.

Assambled on the robotic cells are based on polyarticulated robots using a high frequency generator, or a simple blade.

Machines with one or several robots (STAUBLI, ABB…) according to the production volumes requested (can be used non-stop in 3 shifts).

Oscillator with maximum power output of 500 W enables powerful cutting of difficult-to-cut and extra-tough materials. Signals for on/off, emergency stop, change of output level, and other features can perform with automated machinery or industrial robots.

| Frequency | 40Khz |

|---|---|

| Frequency adjustment | Auto-tracking type |

| Max. power output | 500W |

| Power output | Infinitive adjustment |

| Power supply | AC200V 50/60Hz |

| Electricity consumption | 1000VA |

| Outer dimension (mm) | 120*120*380 |

| External control | on/off, Emergency stop, Change of output |

| Weight | 8kg |

| Blade thickness | 0.6mm |

Target Materials

Resin plate

Glass fiber (GFRP)

Formed decorative film

Foam

Blow-molded parts

Injection-molded parts

Carbon fiber (CFRP)

Aluminum foil composites

Non-woven fabrics

Controlled-depth kiss cutting

FEATURES

| Name | Ultrasonic Cutting Pencil | Frequency | 35Khz |

|---|---|---|---|

| Power | 500w | Type | Light Al |

| Cutting Blade | Titanium Alloy Blade | Blade | Easy Replace |

| High Light | ultrasonic cutting machine,portable ultrasonic cutter | ||

Ultrasonic Cutting Machine is a class of device using ultrasonic energy for cutting. Instead of using traditional blade cutting, ultrasonic cutting has its advantages of smooth, reliable cutting, accurate trimming, no deformation, no raising, fuzzing, spinning, wrinkling etc. It can avoid the rough cutting-edge, coked edge, fuzzballs and other shortcomings of laser cutting machine.

Ultrasonic cutting machine is used for cutting rubber, synthetic fabric, cloth, plastic, sheet metal, food etc.

The cutting of food products using ultrasound is performed when an ultrasonic blade comes into contact with the product to be cut, the high vibration of 40,000 pulses per second, makes this product very easily be cut even if it is of delicate or sticky texture composition. The much higher vibration does not allow any product to stick to the blade. The cut is clean and without pressure on the product.

This Ultrasonic Cutter is designed compact and lightweight with an easy hand grip to reduce fatigue allowing for long continuous operation. This ideal NSK handpiece offers excellent maneuverability with no vibration to the hand ensuring an accurate and sharp cutting finish. The controller automatically adjusts the output power depending on the load so there is no need to make any adjustments on the controller during the working process. A constant frequency provides steady cutting results. From simple work to fine cutting and complicated shapes, this Ultrasonic cutting Knife performs effortlessly and beautifully.

Ultrasonic Cutters are small in size and do not require large installation areas. Special equipment is not required for the installation. Ultrasonic Cutters are small enough to be hand-held for many operations.

Ultrasonic Cutters can also be attached to automated machinery arms. Although they may not be familiar to you, they play an active role in the manufacturing processes of various industrial products which we use daily.cutt-welding of thermoplastic or thermoplastic coated fabrics and fleeces. Thereby two layers one obove the other are cut and the edges are welded together at the same time.

An even more compact and powerful high frequency ultrasonic cutter than previous models results in a sharper cut. User-friendly design fully utilizes the robot’s operation area. A forced cooling system with air inlet enables extended continuous use.

Assambled on the robotic cells are based on polyarticulated robots using a high frequency generator, or a simple blade.

Machines with one or several robots (STAUBLI, ABB…) according to the production volumes requested (can be used non-stop in 3 shifts).

Oscillator with maximum power output of 500 W enables powerful cutting of difficult-to-cut and extra-tough materials. Signals for on/off, emergency stop, change of output level, and other features can perform with automated machinery or industrial robots.

| Frequency | 40Khz |

|---|---|

| Frequency adjustment | Auto-tracking type |

| Max. power output | 500W |

| Power output | Infinitive adjustment |

| Power supply | AC200V 50/60Hz |

| Electricity consumption | 1000VA |

| Outer dimension (mm) | 120*120*380 |

| External control | on/off, Emergency stop, Change of output |

| Weight | 8kg |

| Blade thickness | 0.6mm |

Target Materials

Resin plate

Glass fiber (GFRP)

Formed decorative film

Foam

Blow-molded parts

Injection-molded parts

Carbon fiber (CFRP)

Aluminum foil composites

Non-woven fabrics

Controlled-depth kiss cutting

FEATURES

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!