loading

| Availability: | |

|---|---|

| Quantity: | |

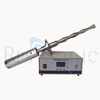

RPS-SONO20

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-C40-50 |

| Minimum Order Quantity | 1set |

| Reactor Material | Stainless Steel | Horn Material | Titanium |

|---|---|---|---|

| Capacity | 20L | Ultrasonic Cavitation Intensity | 0~5(w/cm²) |

| Frequency | 20Khz | Application | Graphene Dispersion |

| High Light | Graphene Dispersion Ultrasonic Liquid Processor,Sonochemical Ultrasonic Liquid Processor,PLC Ultrasonic Liquid Processor | ||

High Power Ultrasonic Sonochemical Processing For Graphene Dispersion

Principle of Ultrasonic Graphene Dispersion

Ultrasonic graphene dispersion equipment uses ultrasonic cavitation to disperse agglomerated particles. It is to put the particle suspension (liquid) to be processed into a super-strong sound field and process it with an appropriate ultrasonic amplitude. Under the additional effects of cavitation, high temperature, high pressure, micro jets, strong vibration, etc., the distance between molecules will increase continuously, which will eventually cause the molecules to break and form a single molecular structure. This product is especially effective for dispersing nanomaterials (such as carbon nanotubes, graphene, silicon dioxide, etc.).

Graphene dispersion purpose

There are a lot of graphite materials in nature, and graphite with a thickness of 1 mm contains about 3 million layers of graphene. Single-layer graphite is called graphene, which does not exist in the free state, and it exists in the form of graphite sheets laminated with multiple layers of graphene. Since the interlayer force of the graphite sheet is weak, it can be exfoliated layer by layer by external force, thereby obtaining a single-layer graphene with a thickness of only one carbon atom.

Ultrasonic-assisted liquid phase exfoliation greatly improves the efficiency of graphene extraction.The application of ultrasonic equipment in the preparation of graphene is mainly in the volumetric thermal layer method and the redox method. These two methods are simpler to operate and cost less than other preparation methods. Due to the cavitation in the liquid, the micro-jet, vibration and other phenomena are formed.

The application of ultrasonic equipment in the preparation of graphene is mainly in the volumetric thermal layer method and the redox method. These two methods are simpler to operate and cost less than other preparation methods. Due to the cavitation in the liquid, the micro-jet, vibration and other phenomena are formed.

1. Reliable for heavy duty sonication processes

2. 24*7 hours continuous operation

3. Industrial grade

4. Colored touch display

5. PLC remote control

6. Automatic Frequency tuning

| Model | RPS-C40-50 |

| Frequency | 20Khz |

| Working frequency | 20KHz |

| Rated power | 3KW |

| Working power | 30%-100% of the rated power, the greater load, the greater power. |

| Amplitude | 0-100μm.Adjustable range:50%-100%. |

| Working temperature | <300℃ |

| Ultrasonic cavitation intensity | 0~5(w/cm²) |

| Reactor material | 304/316 stainless steel |

| Working time | 24H/D |

| Packing size | 210*60*160cm |

| G.W. | 330KGS |

| Reactor Material | Stainless Steel | Horn Material | Titanium |

|---|---|---|---|

| Capacity | 20L | Ultrasonic Cavitation Intensity | 0~5(w/cm²) |

| Frequency | 20Khz | Application | Graphene Dispersion |

| High Light | Graphene Dispersion Ultrasonic Liquid Processor,Sonochemical Ultrasonic Liquid Processor,PLC Ultrasonic Liquid Processor | ||

High Power Ultrasonic Sonochemical Processing For Graphene Dispersion

Principle of Ultrasonic Graphene Dispersion

Ultrasonic graphene dispersion equipment uses ultrasonic cavitation to disperse agglomerated particles. It is to put the particle suspension (liquid) to be processed into a super-strong sound field and process it with an appropriate ultrasonic amplitude. Under the additional effects of cavitation, high temperature, high pressure, micro jets, strong vibration, etc., the distance between molecules will increase continuously, which will eventually cause the molecules to break and form a single molecular structure. This product is especially effective for dispersing nanomaterials (such as carbon nanotubes, graphene, silicon dioxide, etc.).

Graphene dispersion purpose

There are a lot of graphite materials in nature, and graphite with a thickness of 1 mm contains about 3 million layers of graphene. Single-layer graphite is called graphene, which does not exist in the free state, and it exists in the form of graphite sheets laminated with multiple layers of graphene. Since the interlayer force of the graphite sheet is weak, it can be exfoliated layer by layer by external force, thereby obtaining a single-layer graphene with a thickness of only one carbon atom.

Ultrasonic-assisted liquid phase exfoliation greatly improves the efficiency of graphene extraction.The application of ultrasonic equipment in the preparation of graphene is mainly in the volumetric thermal layer method and the redox method. These two methods are simpler to operate and cost less than other preparation methods. Due to the cavitation in the liquid, the micro-jet, vibration and other phenomena are formed.

The application of ultrasonic equipment in the preparation of graphene is mainly in the volumetric thermal layer method and the redox method. These two methods are simpler to operate and cost less than other preparation methods. Due to the cavitation in the liquid, the micro-jet, vibration and other phenomena are formed.

1. Reliable for heavy duty sonication processes

2. 24*7 hours continuous operation

3. Industrial grade

4. Colored touch display

5. PLC remote control

6. Automatic Frequency tuning

| Model | RPS-C40-50 |

| Frequency | 20Khz |

| Working frequency | 20KHz |

| Rated power | 3KW |

| Working power | 30%-100% of the rated power, the greater load, the greater power. |

| Amplitude | 0-100μm.Adjustable range:50%-100%. |

| Working temperature | <300℃ |

| Ultrasonic cavitation intensity | 0~5(w/cm²) |

| Reactor material | 304/316 stainless steel |

| Working time | 24H/D |

| Packing size | 210*60*160cm |

| G.W. | 330KGS |

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!