loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-LP20 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 100~1500w |

|---|---|---|---|

| Horn Material | Titanium | Horn Size | Customized |

| Generator | Digital | Weight | 20kg |

| Package | Carton | Warranty | One Year |

| High Light | Ultrasonic Liquid Processor 20kHz,Digital Sonochemistry Ultrasonic Liquid Processor,Emulsification Ultrasonic Liquid Processor | ||

Description

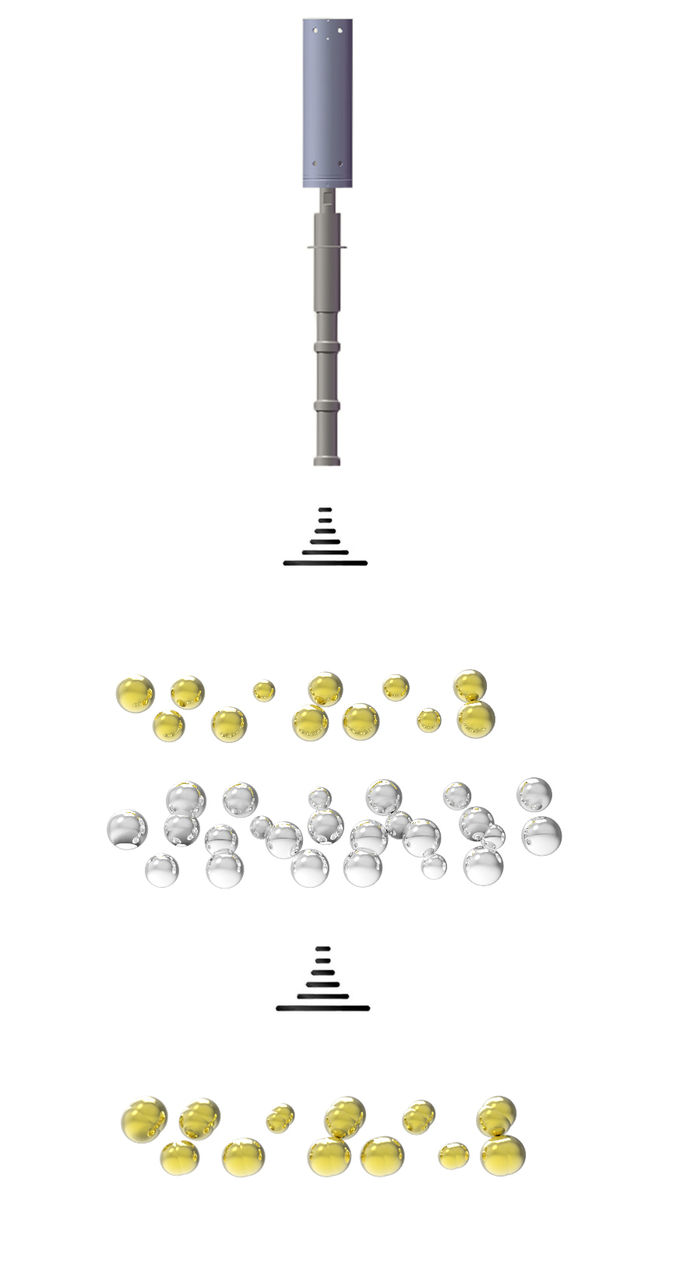

Under the action of ultrasonic energy, two or more immiscible liquids are mixed together, one of which is uniformly dispersed in the other liquid to form an emulsion liquid. This treatment process is called ultrasonic emulsification.

All kinds of intermediates and consumer products, such as cosmetics and skin care products, pharmaceutical creams, paints, lubricants and fuels are all or part of emulsions. Emulsions exist in all aspects of life. Knowing how to control and optimize performance is essential to produce high-quality products. Quality is defined as being suitable for the final application.

Different industries have very different emulsion manufacturing processes. These differences include the components used (mixtures, including various components in the solution), emulsification methods, and more processing conditions. Emulsion is a dispersion of two or more immiscible liquids. High-intensity ultrasound is provided to disperse the liquid phase (dispersed phase) in the small droplets of another second phase (continuous phase). energy.

Two liquids can form different types of emulsions, for example, oil and water. First, oil-in-water emulsions, where oil is the dispersed phase and water is the dispersion medium. Second, they can form water-in-oil emulsions, where water is the dispersed phase and oil is the continuous phase. It is also possible to form multiple emulsions, including "water-in-oil-in-water" emulsions and "oil-in-water-in-oil" emulsions.

Parameter

| Item | Parameter |

| Frequency | 20Khz |

| Power | 1000w |

| Capacity | 0.5~5L |

| Horn diameter | 16mm |

| Probe dip depth | 80mm |

Applications

Ultrasonic emulsification technology has been widely used in food, paper, paint, chemical, pharmaceutical, textile, petroleum, metallurgy and other industrial fields. Ultrasonic equipment can be easily installed on existing production lines, which is convenient for manufacturers to upgrade equipment at a lower cost. . Ultrasonic emulsification can also create emulsions that do not work in general methods. The commonly used mixing method can only produce 5% paraffin wax in water. It is incredible that under the action of power ultrasound, 20% paraffin wax emulsion can be produced.

Features

The type of emulsion can be controlled.

The power required to produce the emulsion is small.

The formed emulsion is more stable, and some are stable for several months to more than half a year.

The concentration is high, the concentration of pure emulsion can exceed 30%, and the addition of emulsifier can reach 70%.

Low cost, an important feature of ultrasonic emulsification is that it can produce a very stable emulsion without or with less emulsifiers.

Compared with general emulsification technology and equipment (such as propeller, colloid mill and homogenizer, etc.), ultrasonic emulsification has many advantages.

The average droplet size of the formed emulsion is small (0.2~2 microns), and the droplet size distribution range is narrow (0.1-10 microns) or narrower.

The range of application of sonochemistry reactor

• Dispersion

• Cell disruption

• Pharmacy sample prep

• Homogenization

• Emulsification

• Nanoparticle dispersion

• Atomization

• Graphene dispersion

• Biodiesel making;

• Liquidation,

• Crystallization,

• Extraction,

• Wastewater treatment,

• Accelerated reaction,

• kill microbes(cell disruption),

• Degradation of toxic organic pollutants

• antiscaling descaling in sewage treatment field

Pictures

| Frequency | 20Khz | Power | 100~1500w |

|---|---|---|---|

| Horn Material | Titanium | Horn Size | Customized |

| Generator | Digital | Weight | 20kg |

| Package | Carton | Warranty | One Year |

| High Light | Ultrasonic Liquid Processor 20kHz,Digital Sonochemistry Ultrasonic Liquid Processor,Emulsification Ultrasonic Liquid Processor | ||

Description

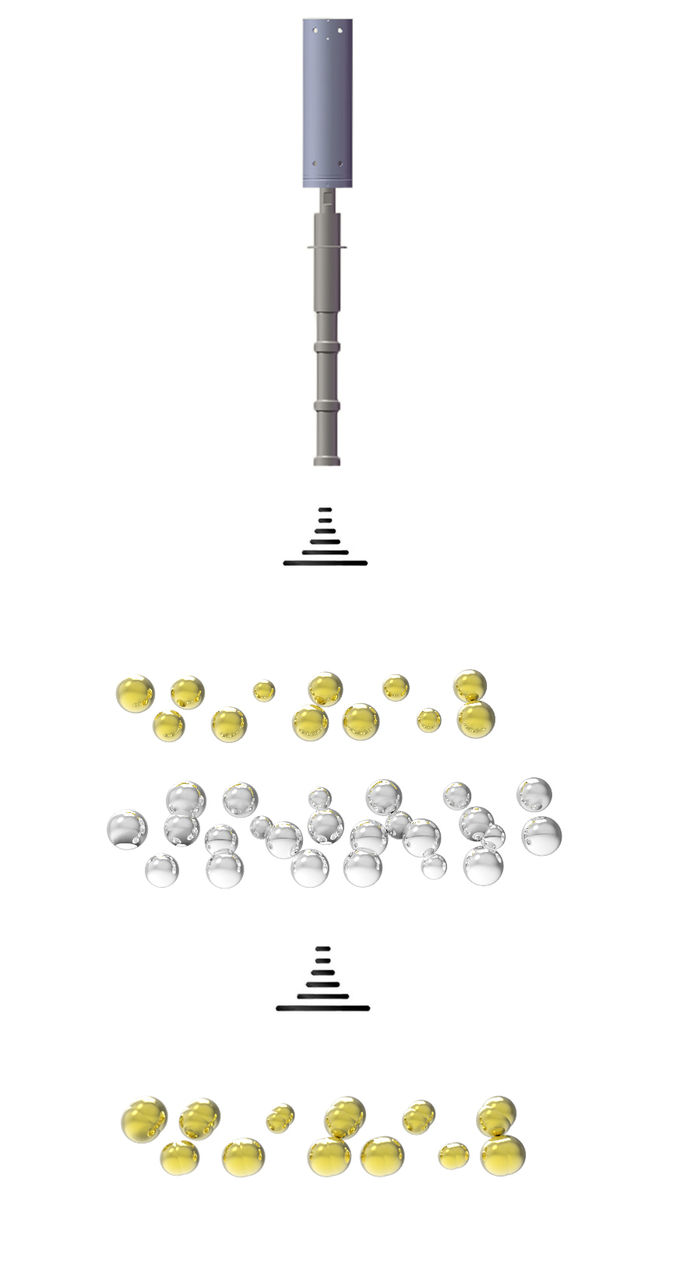

Under the action of ultrasonic energy, two or more immiscible liquids are mixed together, one of which is uniformly dispersed in the other liquid to form an emulsion liquid. This treatment process is called ultrasonic emulsification.

All kinds of intermediates and consumer products, such as cosmetics and skin care products, pharmaceutical creams, paints, lubricants and fuels are all or part of emulsions. Emulsions exist in all aspects of life. Knowing how to control and optimize performance is essential to produce high-quality products. Quality is defined as being suitable for the final application.

Different industries have very different emulsion manufacturing processes. These differences include the components used (mixtures, including various components in the solution), emulsification methods, and more processing conditions. Emulsion is a dispersion of two or more immiscible liquids. High-intensity ultrasound is provided to disperse the liquid phase (dispersed phase) in the small droplets of another second phase (continuous phase). energy.

Two liquids can form different types of emulsions, for example, oil and water. First, oil-in-water emulsions, where oil is the dispersed phase and water is the dispersion medium. Second, they can form water-in-oil emulsions, where water is the dispersed phase and oil is the continuous phase. It is also possible to form multiple emulsions, including "water-in-oil-in-water" emulsions and "oil-in-water-in-oil" emulsions.

Parameter

| Item | Parameter |

| Frequency | 20Khz |

| Power | 1000w |

| Capacity | 0.5~5L |

| Horn diameter | 16mm |

| Probe dip depth | 80mm |

Applications

Ultrasonic emulsification technology has been widely used in food, paper, paint, chemical, pharmaceutical, textile, petroleum, metallurgy and other industrial fields. Ultrasonic equipment can be easily installed on existing production lines, which is convenient for manufacturers to upgrade equipment at a lower cost. . Ultrasonic emulsification can also create emulsions that do not work in general methods. The commonly used mixing method can only produce 5% paraffin wax in water. It is incredible that under the action of power ultrasound, 20% paraffin wax emulsion can be produced.

Features

The type of emulsion can be controlled.

The power required to produce the emulsion is small.

The formed emulsion is more stable, and some are stable for several months to more than half a year.

The concentration is high, the concentration of pure emulsion can exceed 30%, and the addition of emulsifier can reach 70%.

Low cost, an important feature of ultrasonic emulsification is that it can produce a very stable emulsion without or with less emulsifiers.

Compared with general emulsification technology and equipment (such as propeller, colloid mill and homogenizer, etc.), ultrasonic emulsification has many advantages.

The average droplet size of the formed emulsion is small (0.2~2 microns), and the droplet size distribution range is narrow (0.1-10 microns) or narrower.

The range of application of sonochemistry reactor

• Dispersion

• Cell disruption

• Pharmacy sample prep

• Homogenization

• Emulsification

• Nanoparticle dispersion

• Atomization

• Graphene dispersion

• Biodiesel making;

• Liquidation,

• Crystallization,

• Extraction,

• Wastewater treatment,

• Accelerated reaction,

• kill microbes(cell disruption),

• Degradation of toxic organic pollutants

• antiscaling descaling in sewage treatment field

Pictures

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!