loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-SW28 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 28Khz | Power | 800w |

|---|---|---|---|

| Horn Material | Titanium | Horn Size | Customized |

| Generator | Digital | Weight | 6kg |

| Warranty | One Year | Package | Carton |

| High Light | 800w Ultrasonic Spot Welding Machine,28Khz Ultrasonic Spot Welding Machine,Analog Generator Ultrasonic Spot Welder | ||

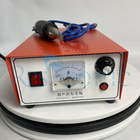

Analog Generator Ultrasonic Spot Welding 28Khz 800w For Ribbon Welding

28Khz 800w Ultrasonic spot welding machine for ribbon welding with analog generator

Parameter

| Item | Parameter | Advantage: | Application |

| 28Khz ultrasonic hand welder Straight type | 28Khz 800W Digital generator Horn customized Aluminum alloy&Steel & Titanium alloy Power Supply: 220v 50/60HZ | 1. light generator ,light hand welder.The generator 120*120*380, whole weight5KG, with generator 4kg, and the 28Khz hand welder 1kg, 35Khz hand welder 0.8kg. Suit for hand operate. 2. Special alloy metal housing, the housing of the hand-welder is light but firm, not easy to be deformed, longer it’d using life. 3. Digital generator, it can tracking the frequency itself, easy for operate. Output /welding time adjustable, suit for both hand operate and machine operate. | PP PVC Fabric woven PE ABS PS Nylon PU PET All Thermoplastic material, the thickness 8mm in max.

Straight type suit for both hand /machine operate. Gun type suit for hand operate.

|

|

28Khz ultrasonic hand welder Gun type | |||

| 35Khz ultrasonic hand welder Straight type | 35Khz 500W Digital generator Horn customized Aluminum alloy&Steel & Titanium alloy Power Supply: 220v 50/60HZ | PP PVC Fabric woven PE ABS PS Nylon PU PET All Thermoplastic material, the thickness 5mm in max.

Straight type suit for both hand /machine operate. Gun type suit for hand operate.

| |

| 35Khz ultrasonic hand welder Gun type | |||

| For better application , it is better share all the material information with me, the material, thickness, operate way, speed requirements before order . We also supply 20Khz 40Khz ultrasonic hand-weld welder. | |||

Description

Ultrasonic welding is a high-tech technology for connecting thermoplastic plastic products. All kinds of thermoplastic rubber parts can be processed by ultrasonic welding without adding solvents, adhesives or other auxiliary products. Its advantages are to increase productivity by multiple times, reduce costs, improve product quality and safe production.

The principle of ultrasonic plastic welding is that a generator generates a high-voltage and high-frequency signal of 208Hz (or 15KHz). The signal is converted into a high-frequency mechanical vibration through an energy conversion system. Friction increases the temperature transmitted to the interface. When the temperature reaches the training point of the workpiece itself, the interface of the workpiece is quickly cultivated, and then fills the gap between the interfaces. When the vibration stops, the workpiece is cooled and shaped under a certain pressure at the same time , To achieve perfect welding.

The new 15KHz ultrasonic plastic welding machine, for welding softer PE and PP materials, as well as plastic weldments with extra large diameter and long length, has a unique effect, can meet the needs of various products, and can provide users with production efficiency and product grades. contribute.

Ultrasonic welding process

1. Ultrasonic welding:

Under moderate pressure, the ultrasonic head vibrating at ultra-high frequency makes the bonding surface of the two plastics generate heat and inter-mass fusion bonding. The use of suitable workpieces and reasonable interface design can achieve water and air tightness. Eliminate the inconvenience caused by the use of auxiliary products, and achieve efficient and clean welding strength that can be compared with the main body Weimei.

2. Riveting and welding method: Pressing the protruding tip of the plastic limb with the powerful head that attracts ultra-high frequency vibration of the sound wave, so that the heat between the tyrants is melted into a riveting shape, and the village material mechanical willows of different materials are combined together. 3. Implantation: By means of the conduction of the welding head and proper compression, the metal parts (such as construction mother, screw, etc.) will be squeezed into the reserved rubber hole in a certain depth. After completion, regardless of the tension and force It can be comparable to the strength of the traditional mold, and it can avoid the shortcomings of damage to the injection mold and slow injection.

Features

A. It can weld thermoplastic plastics other than Teflon.

B. The splicing time is extremely short, usually ranging from 0.05 seconds to 1 second.

C. It can be welded to the joint surface through media such as water, oil, etc.

D. The welding effect can reach a practical level. E. It can be directly welded with Fu Dao.

F. Material welding energy varies with plastic materials, and not all ultrasonic vibration materials. Only select suitable vibration heat stations. The product surface is free from scratches. This is the characteristic of the transfer baking. When the harder plastic is welded,

It can give full play to its baking effect.

G. Ultrasonic welding will not produce the toxicity like chemicals, and it is a safe welding process.

| Frequency | 28Khz | Power | 800w |

|---|---|---|---|

| Horn Material | Titanium | Horn Size | Customized |

| Generator | Digital | Weight | 6kg |

| Warranty | One Year | Package | Carton |

| High Light | 800w Ultrasonic Spot Welding Machine,28Khz Ultrasonic Spot Welding Machine,Analog Generator Ultrasonic Spot Welder | ||

Analog Generator Ultrasonic Spot Welding 28Khz 800w For Ribbon Welding

28Khz 800w Ultrasonic spot welding machine for ribbon welding with analog generator

Parameter

| Item | Parameter | Advantage: | Application |

| 28Khz ultrasonic hand welder Straight type | 28Khz 800W Digital generator Horn customized Aluminum alloy&Steel & Titanium alloy Power Supply: 220v 50/60HZ | 1. light generator ,light hand welder.The generator 120*120*380, whole weight5KG, with generator 4kg, and the 28Khz hand welder 1kg, 35Khz hand welder 0.8kg. Suit for hand operate. 2. Special alloy metal housing, the housing of the hand-welder is light but firm, not easy to be deformed, longer it’d using life. 3. Digital generator, it can tracking the frequency itself, easy for operate. Output /welding time adjustable, suit for both hand operate and machine operate. | PP PVC Fabric woven PE ABS PS Nylon PU PET All Thermoplastic material, the thickness 8mm in max.

Straight type suit for both hand /machine operate. Gun type suit for hand operate.

|

|

28Khz ultrasonic hand welder Gun type | |||

| 35Khz ultrasonic hand welder Straight type | 35Khz 500W Digital generator Horn customized Aluminum alloy&Steel & Titanium alloy Power Supply: 220v 50/60HZ | PP PVC Fabric woven PE ABS PS Nylon PU PET All Thermoplastic material, the thickness 5mm in max.

Straight type suit for both hand /machine operate. Gun type suit for hand operate.

| |

| 35Khz ultrasonic hand welder Gun type | |||

| For better application , it is better share all the material information with me, the material, thickness, operate way, speed requirements before order . We also supply 20Khz 40Khz ultrasonic hand-weld welder. | |||

Description

Ultrasonic welding is a high-tech technology for connecting thermoplastic plastic products. All kinds of thermoplastic rubber parts can be processed by ultrasonic welding without adding solvents, adhesives or other auxiliary products. Its advantages are to increase productivity by multiple times, reduce costs, improve product quality and safe production.

The principle of ultrasonic plastic welding is that a generator generates a high-voltage and high-frequency signal of 208Hz (or 15KHz). The signal is converted into a high-frequency mechanical vibration through an energy conversion system. Friction increases the temperature transmitted to the interface. When the temperature reaches the training point of the workpiece itself, the interface of the workpiece is quickly cultivated, and then fills the gap between the interfaces. When the vibration stops, the workpiece is cooled and shaped under a certain pressure at the same time , To achieve perfect welding.

The new 15KHz ultrasonic plastic welding machine, for welding softer PE and PP materials, as well as plastic weldments with extra large diameter and long length, has a unique effect, can meet the needs of various products, and can provide users with production efficiency and product grades. contribute.

Ultrasonic welding process

1. Ultrasonic welding:

Under moderate pressure, the ultrasonic head vibrating at ultra-high frequency makes the bonding surface of the two plastics generate heat and inter-mass fusion bonding. The use of suitable workpieces and reasonable interface design can achieve water and air tightness. Eliminate the inconvenience caused by the use of auxiliary products, and achieve efficient and clean welding strength that can be compared with the main body Weimei.

2. Riveting and welding method: Pressing the protruding tip of the plastic limb with the powerful head that attracts ultra-high frequency vibration of the sound wave, so that the heat between the tyrants is melted into a riveting shape, and the village material mechanical willows of different materials are combined together. 3. Implantation: By means of the conduction of the welding head and proper compression, the metal parts (such as construction mother, screw, etc.) will be squeezed into the reserved rubber hole in a certain depth. After completion, regardless of the tension and force It can be comparable to the strength of the traditional mold, and it can avoid the shortcomings of damage to the injection mold and slow injection.

Features

A. It can weld thermoplastic plastics other than Teflon.

B. The splicing time is extremely short, usually ranging from 0.05 seconds to 1 second.

C. It can be welded to the joint surface through media such as water, oil, etc.

D. The welding effect can reach a practical level. E. It can be directly welded with Fu Dao.

F. Material welding energy varies with plastic materials, and not all ultrasonic vibration materials. Only select suitable vibration heat stations. The product surface is free from scratches. This is the characteristic of the transfer baking. When the harder plastic is welded,

It can give full play to its baking effect.

G. Ultrasonic welding will not produce the toxicity like chemicals, and it is a safe welding process.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!