loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-M20-R |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

| Horn Material | Soft Steel Titanium Alloy | Amplitude | 15 - 50 µm |

| Wear Ratio | Tungsten 1.5:1 And Glass 100:1 | Gap Overcut | 0.02-0.1 Mm |

| Grit Size(d0) | 100 – 800 | ||

| High Light | 1000w Ultrasonic Milling Machine,Ultrasonic Milling Machine Non Contact | ||

Description

Ultrasonic processing is a special processing that uses ultrasonic frequency to make small amplitude vibration tools, and through the impact of the abrasive free in the liquid between it and the workpiece on the surface to be processed, the surface of the workpiece material is gradually broken. Ultrasonic machining is often used for piercing, cutting, welding, nesting and polishing.

Ultrasonic vibration cutting is a kind of pulse cutting microscopically. In a vibration cycle, the effective cutting time is very short, and it is completely separated from the workpiece and the chips for more than 80% of the time. The intermittent contact with the workpiece and the chips reduces the friction, the heat generated is greatly reduced, and the cutting force is significantly reduced, which avoids the "knife" phenomenon in ordinary cutting, and does not produce built-up edge. Using this kind of vibration cutting, precision machining can be performed on ordinary machine tools. The geometric tolerances such as roundness, cylindricity, flatness, parallelism, straightness, etc. mainly depend on the accuracy of the machine tool spindle and guide rail, and can reach nearly zero error. It is possible to replace grinding by car, reaming by drilling, and grinding by milling. Compared with high-speed hard cutting, it does not require high machine tool rigidity and does not damage the metallographic structure of the workpiece surface. In the finish machining of curved contour parts, it is possible to use CNC lathes, machining centers, etc. for profiling machining, which can save the expensive purchase cost of CNC grinding machines.

Brief introduction

1 The cutting force is small, about 1/3-1/10 of the ordinary cutting force.

2 The machining accuracy is high, which mainly depends on the accuracy of the machine tool used, and the shape and position tolerance of the processed workpiece can almost be close to the relevant accuracy of the machine tool.

3 The cutting temperature is low, and the workpiece is kept at room temperature.

4 There is no built-up edge, small deformation of the workpiece, and no burrs.

Advantage

1. Using non-contact rotating ultrasonic tool holder, brushless non-contact power transmission, high transmission efficiency.

2. Ultrasonic milling force is small, about 1/3-1/10 of the milling force of ordinary tools.

3. The high precision of ultrasonic turning mainly depends on the precision of the machine tool used, and the shape and position tolerance of the processed workpiece is almost close to that of the machine tool.

Accuracy.

4. Ultrasonic milling temperature is low, and the workpiece is kept at room temperature.

5. No built-up edge, small deformation of the workpiece, and no burrs.

6. The surface roughness of ultrasonic milling is low, which can be close to the theoretical roughness value, which can reach Ra0.2 or less.

7. The "rigidization" of ultrasonically machined parts is equivalent to the increase in rigidity of the workpiece compared with ordinary milling.

8. The ultrasonic machining process is stable and can effectively eliminate chattering.

9. The cooling and lubricating effect of ultrasonic milling fluid is improved.

10. The tool durability has been improved several times to several tens of times.

11. The ultrasonically processed surface is in a state of compressive stress, and the fatigue, wear resistance and corrosion resistance of the parts are improved.

12. The surface of the workpiece after ultrasonic turning shows a rainbow effect.

Parameter

| Item | Parameter |

| Abrasive | Boron carbide, aluminium oxide and silicon carbide |

| Grit size(d0) | 100 – 800 |

| Frequency of vibration (f) | 19 – 25 kHz |

| Amplitude of vibration (a) | 15 - 50 µm |

| Tool material | Soft steel titanium alloy |

| Wear ratio | Tungsten 1.5:1 and glass 100:1 |

| Gap overcut | 0.02-0.1 mm |

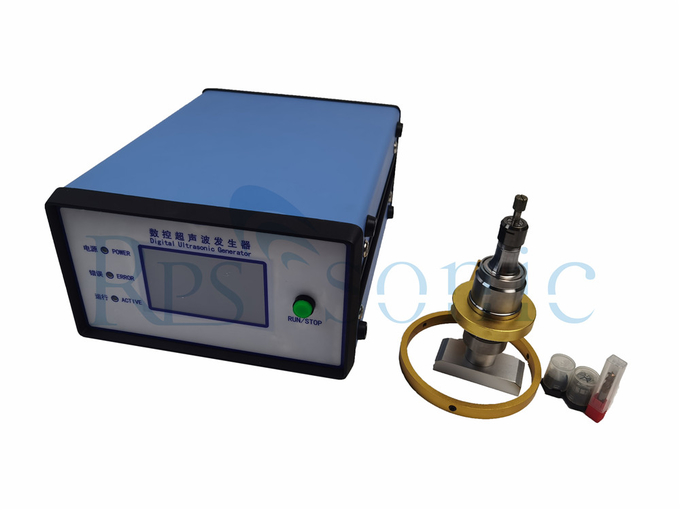

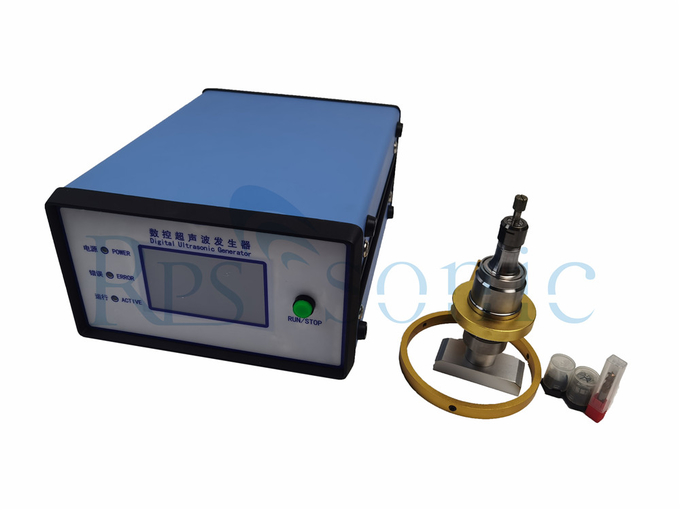

Pictures

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

| Horn Material | Soft Steel Titanium Alloy | Amplitude | 15 - 50 µm |

| Wear Ratio | Tungsten 1.5:1 And Glass 100:1 | Gap Overcut | 0.02-0.1 Mm |

| Grit Size(d0) | 100 – 800 | ||

| High Light | 1000w Ultrasonic Milling Machine,Ultrasonic Milling Machine Non Contact | ||

Description

Ultrasonic processing is a special processing that uses ultrasonic frequency to make small amplitude vibration tools, and through the impact of the abrasive free in the liquid between it and the workpiece on the surface to be processed, the surface of the workpiece material is gradually broken. Ultrasonic machining is often used for piercing, cutting, welding, nesting and polishing.

Ultrasonic vibration cutting is a kind of pulse cutting microscopically. In a vibration cycle, the effective cutting time is very short, and it is completely separated from the workpiece and the chips for more than 80% of the time. The intermittent contact with the workpiece and the chips reduces the friction, the heat generated is greatly reduced, and the cutting force is significantly reduced, which avoids the "knife" phenomenon in ordinary cutting, and does not produce built-up edge. Using this kind of vibration cutting, precision machining can be performed on ordinary machine tools. The geometric tolerances such as roundness, cylindricity, flatness, parallelism, straightness, etc. mainly depend on the accuracy of the machine tool spindle and guide rail, and can reach nearly zero error. It is possible to replace grinding by car, reaming by drilling, and grinding by milling. Compared with high-speed hard cutting, it does not require high machine tool rigidity and does not damage the metallographic structure of the workpiece surface. In the finish machining of curved contour parts, it is possible to use CNC lathes, machining centers, etc. for profiling machining, which can save the expensive purchase cost of CNC grinding machines.

Brief introduction

1 The cutting force is small, about 1/3-1/10 of the ordinary cutting force.

2 The machining accuracy is high, which mainly depends on the accuracy of the machine tool used, and the shape and position tolerance of the processed workpiece can almost be close to the relevant accuracy of the machine tool.

3 The cutting temperature is low, and the workpiece is kept at room temperature.

4 There is no built-up edge, small deformation of the workpiece, and no burrs.

Advantage

1. Using non-contact rotating ultrasonic tool holder, brushless non-contact power transmission, high transmission efficiency.

2. Ultrasonic milling force is small, about 1/3-1/10 of the milling force of ordinary tools.

3. The high precision of ultrasonic turning mainly depends on the precision of the machine tool used, and the shape and position tolerance of the processed workpiece is almost close to that of the machine tool.

Accuracy.

4. Ultrasonic milling temperature is low, and the workpiece is kept at room temperature.

5. No built-up edge, small deformation of the workpiece, and no burrs.

6. The surface roughness of ultrasonic milling is low, which can be close to the theoretical roughness value, which can reach Ra0.2 or less.

7. The "rigidization" of ultrasonically machined parts is equivalent to the increase in rigidity of the workpiece compared with ordinary milling.

8. The ultrasonic machining process is stable and can effectively eliminate chattering.

9. The cooling and lubricating effect of ultrasonic milling fluid is improved.

10. The tool durability has been improved several times to several tens of times.

11. The ultrasonically processed surface is in a state of compressive stress, and the fatigue, wear resistance and corrosion resistance of the parts are improved.

12. The surface of the workpiece after ultrasonic turning shows a rainbow effect.

Parameter

| Item | Parameter |

| Abrasive | Boron carbide, aluminium oxide and silicon carbide |

| Grit size(d0) | 100 – 800 |

| Frequency of vibration (f) | 19 – 25 kHz |

| Amplitude of vibration (a) | 15 - 50 µm |

| Tool material | Soft steel titanium alloy |

| Wear ratio | Tungsten 1.5:1 and glass 100:1 |

| Gap overcut | 0.02-0.1 mm |

Pictures

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!