loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-S35 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

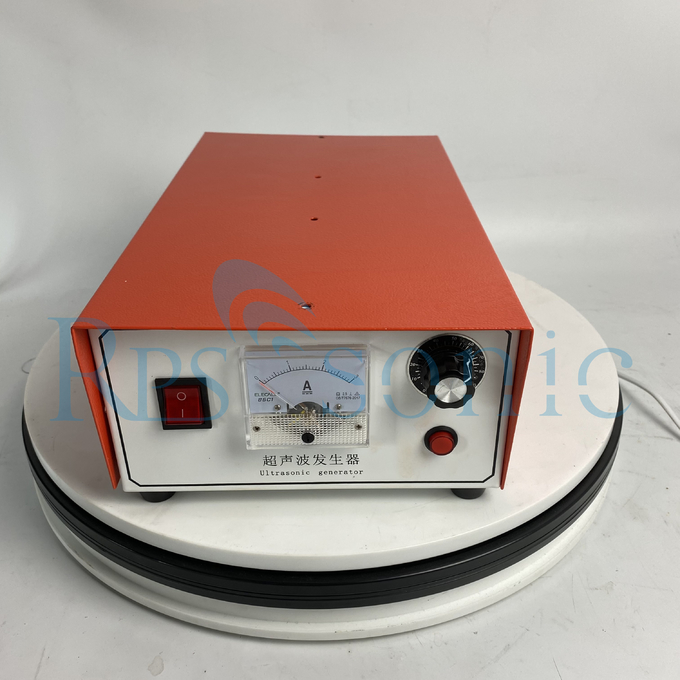

| Frequency | 35Khz | Power | 600w |

|---|---|---|---|

| Type | Analog | Weight | 4.5kg |

| Application | Ultrasonic Spot Welding | Color | Red |

| High Light | 35khz Analog Frequency Generator,Plastic Spot Welding Analog Frequency Generator | ||

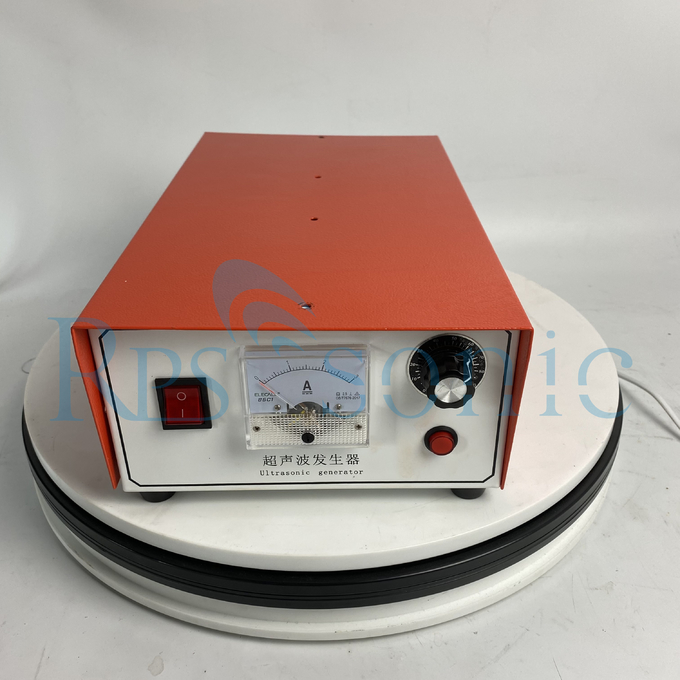

28khz 35khz Analog Frequency Generator For Ultrasonic Plastic Spot Welding

28khz/35khz High Stable Ultrasonic analog generator for plastic welding nonwoven welding

Ultrasonic spot welding is used whenever large plastic parts cannot be placed on a traditional machine. Therefore, the welding head designed as a handgun is brought to the part; either manually or with a robot. The advantage of ultrasonic spot welding is the fact that the parts do not need any special preparation (no energy director required ).Therefore large size vacuum formed parts can also be assembled easily.

The ultrasonic horn is built to produce high amplitude. The tip of the horn is shaped in order to penetrate the two layers of material,leaving a typical ring pattern on the workface, while the backside rests smiith and clean.

The choice of frequencies is considered according to the diameter of the soldering point, thickness of the materials and their geometries.

If it is provided with a bonding booster, it becomes the ideal instrument for ultrasound spot welding operations in plastic thermoforming, PVC conveyor belts, blisters, automobile parts and acrylic cloths.

The Ultrasonic Generator Features:

| Item | 20 | 28 | 35 | 40 |

| Frequency | 20Khz | 28khz | 35khz | 40khz |

| Power | 800w | 600w | 500w | 300w |

| Horn tip diameter | 12mm | 10mm | 8mm | 8mm |

| Horn material | Aluminum alloy&Steel & Titanium alloy | |||

| Generator | Analog generator | |||

Areas of use:

Automotive industry

Prototype/trials work

Conveyor belt repair

Re-work for automation

Fabric repairs and joining

Blister packs

Vac forming- component retaining

Equipment is mobile

Our hand-held thermoplastic welding tools meet two needs: welding of hard-to-reach areas and tamper-proof sealing of packaging.

In practically no time your production teams will be producing clean welds with our ultrasonic gun and pencil.

These tools are designed for ease of use, adaptability and flexibility to ensure clean and strong welds.

We have the solution to all your assembly needs.

We also have metal housing welding pencil, for welsing machine assembly.

| Frequency | 35Khz | Power | 600w |

|---|---|---|---|

| Type | Analog | Weight | 4.5kg |

| Application | Ultrasonic Spot Welding | Color | Red |

| High Light | 35khz Analog Frequency Generator,Plastic Spot Welding Analog Frequency Generator | ||

28khz 35khz Analog Frequency Generator For Ultrasonic Plastic Spot Welding

28khz/35khz High Stable Ultrasonic analog generator for plastic welding nonwoven welding

Ultrasonic spot welding is used whenever large plastic parts cannot be placed on a traditional machine. Therefore, the welding head designed as a handgun is brought to the part; either manually or with a robot. The advantage of ultrasonic spot welding is the fact that the parts do not need any special preparation (no energy director required ).Therefore large size vacuum formed parts can also be assembled easily.

The ultrasonic horn is built to produce high amplitude. The tip of the horn is shaped in order to penetrate the two layers of material,leaving a typical ring pattern on the workface, while the backside rests smiith and clean.

The choice of frequencies is considered according to the diameter of the soldering point, thickness of the materials and their geometries.

If it is provided with a bonding booster, it becomes the ideal instrument for ultrasound spot welding operations in plastic thermoforming, PVC conveyor belts, blisters, automobile parts and acrylic cloths.

The Ultrasonic Generator Features:

| Item | 20 | 28 | 35 | 40 |

| Frequency | 20Khz | 28khz | 35khz | 40khz |

| Power | 800w | 600w | 500w | 300w |

| Horn tip diameter | 12mm | 10mm | 8mm | 8mm |

| Horn material | Aluminum alloy&Steel & Titanium alloy | |||

| Generator | Analog generator | |||

Areas of use:

Automotive industry

Prototype/trials work

Conveyor belt repair

Re-work for automation

Fabric repairs and joining

Blister packs

Vac forming- component retaining

Equipment is mobile

Our hand-held thermoplastic welding tools meet two needs: welding of hard-to-reach areas and tamper-proof sealing of packaging.

In practically no time your production teams will be producing clean welds with our ultrasonic gun and pencil.

These tools are designed for ease of use, adaptability and flexibility to ensure clean and strong welds.

We have the solution to all your assembly needs.

We also have metal housing welding pencil, for welsing machine assembly.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!