loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-FW20 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 2000w |

|---|---|---|---|

| Welding Width | 0-10mm | Speed | 20m/Min |

| Horn Material | Titanium | Weigh | 150kg |

| High Light | Pleated Filter Ultrasonic Welding Machine,2000w Ultrasonic Welding Machine,Rotary Horn Ultrasonic Welder | ||

20kHz 2000w Ultrasonic Welding Machine For Pleated Filter Welding

20kHz Ultrasonic Welding Machine for pleated Filter Welding with Rotary Horn

Parameter

| ITEM | PARAMETER |

| Frequency | 20Khz |

| Horn | Rotary horn |

| Horn width | 25mm in max |

| welding width | 2mm~25mm |

| Horn material | Steel |

| Generator | DG4200 |

| Operate | Touch screen PLC control |

| Air pressure | 6 bar maximum |

Descriptiom

Filter element is a professional term in the filtration industry. In order to purify the original ecological resources and reuse of resources, purification equipment is needed. Now filter elements are mainly used in filtration industries such as oil filtration, air filtration, and water filtration. The removal of a small amount of solid particles in the liquid or air can protect the normal operation of the equipment or the cleanness of the air. When the fluid enters the filter element with a certain filter screen, its impurities are blocked, and the clean fluid flows out through the filter element. The filter element is welded with two welding technologies: ultrasonic and hot-melt. The welding head vibrating with ultrasonic ultra-high frequency under moderate pressure will cause the joint surface of the two plastics to generate frictional heat and melt and join instantly. The welding strength is comparable to that of the main body. Use appropriate The workpiece and reasonable interface design can achieve water and air tightness, and avoid the inconvenience caused by the use of auxiliary products, and realize efficient and clean welding. Therefore, the ultrasonic welding filter element has unique advantages.

RPS-SONIC ultrasonic professional provides: ultrasonic water dispenser filter element welding machine, ultrasonic water purifier filter element welding machine, ultrasonic air filter element welding machine, ultrasonic chemical fiber material filter element welding machine, ultrasonic medical filter element welding machine, etc.

A rotary ultrasonic assembly mounted in a bearing housing that can be mounted in any orientation. It is available in 20, 35 kHz with bond widths of up to15MM. The bonder is intended for machinery manufacturers and experienced end users who desire to develop their own actuation and tooling solutions. Ultrasonic Sewing Machines operate like a traditional rotary sewing machine but produce soft, smooth seams that are impervious to moisture or fluids.

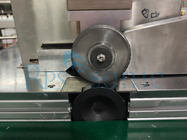

Ultrasonic rotary horn

An ultrasonic rotary horn intended to be excited at a frequency of from about 18 to about 60 kHz, which horn is a shaped, solid object having a rotational axis and a radial surface terminated by a first end and a second end.

The horn is racially symmetrical. The thickness of the horn at the rotational axis is greater than the width of the horn at the radial surface. The diameter, width, and thickness of the horn are selected for a desired frequency so that the horn, upon being excited by ultrasonic energy at such frequency which is input at the rotational axis at, and substantially perpendicular to, one or both ends, is adapted to resonate in a manner such that:

The excited end moves substantially in phase with the movement of the source of excitation.

The opposing end, whether or not it is actively excited, moves substantially out of phase with the movement of the excited end.

The radial work-contacting surface also moves substantially out of phase with the movement of the excited end.

In addition, the first end and the second end have a substantially convex configuration which comprises a central, circular, flat portion which is concentric with the rotational axis and a generally concave portion from the flat portion to said radial

The horn exhibits a single nodal point at its geometric center.

Working ultrasonic rotating horns / sonotrode frequency: 20 kHz, 23 kHz, 25 kHz (sound of silence), 30 kHz, 35 kHz, 36 kHz, and 40 kHz.

Can be anodized or as here wolfram carbide coated for even more ware

| Frequency | 20Khz | Power | 2000w |

|---|---|---|---|

| Welding Width | 0-10mm | Speed | 20m/Min |

| Horn Material | Titanium | Weigh | 150kg |

| High Light | Pleated Filter Ultrasonic Welding Machine,2000w Ultrasonic Welding Machine,Rotary Horn Ultrasonic Welder | ||

20kHz 2000w Ultrasonic Welding Machine For Pleated Filter Welding

20kHz Ultrasonic Welding Machine for pleated Filter Welding with Rotary Horn

Parameter

| ITEM | PARAMETER |

| Frequency | 20Khz |

| Horn | Rotary horn |

| Horn width | 25mm in max |

| welding width | 2mm~25mm |

| Horn material | Steel |

| Generator | DG4200 |

| Operate | Touch screen PLC control |

| Air pressure | 6 bar maximum |

Descriptiom

Filter element is a professional term in the filtration industry. In order to purify the original ecological resources and reuse of resources, purification equipment is needed. Now filter elements are mainly used in filtration industries such as oil filtration, air filtration, and water filtration. The removal of a small amount of solid particles in the liquid or air can protect the normal operation of the equipment or the cleanness of the air. When the fluid enters the filter element with a certain filter screen, its impurities are blocked, and the clean fluid flows out through the filter element. The filter element is welded with two welding technologies: ultrasonic and hot-melt. The welding head vibrating with ultrasonic ultra-high frequency under moderate pressure will cause the joint surface of the two plastics to generate frictional heat and melt and join instantly. The welding strength is comparable to that of the main body. Use appropriate The workpiece and reasonable interface design can achieve water and air tightness, and avoid the inconvenience caused by the use of auxiliary products, and realize efficient and clean welding. Therefore, the ultrasonic welding filter element has unique advantages.

RPS-SONIC ultrasonic professional provides: ultrasonic water dispenser filter element welding machine, ultrasonic water purifier filter element welding machine, ultrasonic air filter element welding machine, ultrasonic chemical fiber material filter element welding machine, ultrasonic medical filter element welding machine, etc.

A rotary ultrasonic assembly mounted in a bearing housing that can be mounted in any orientation. It is available in 20, 35 kHz with bond widths of up to15MM. The bonder is intended for machinery manufacturers and experienced end users who desire to develop their own actuation and tooling solutions. Ultrasonic Sewing Machines operate like a traditional rotary sewing machine but produce soft, smooth seams that are impervious to moisture or fluids.

Ultrasonic rotary horn

An ultrasonic rotary horn intended to be excited at a frequency of from about 18 to about 60 kHz, which horn is a shaped, solid object having a rotational axis and a radial surface terminated by a first end and a second end.

The horn is racially symmetrical. The thickness of the horn at the rotational axis is greater than the width of the horn at the radial surface. The diameter, width, and thickness of the horn are selected for a desired frequency so that the horn, upon being excited by ultrasonic energy at such frequency which is input at the rotational axis at, and substantially perpendicular to, one or both ends, is adapted to resonate in a manner such that:

The excited end moves substantially in phase with the movement of the source of excitation.

The opposing end, whether or not it is actively excited, moves substantially out of phase with the movement of the excited end.

The radial work-contacting surface also moves substantially out of phase with the movement of the excited end.

In addition, the first end and the second end have a substantially convex configuration which comprises a central, circular, flat portion which is concentric with the rotational axis and a generally concave portion from the flat portion to said radial

The horn exhibits a single nodal point at its geometric center.

Working ultrasonic rotating horns / sonotrode frequency: 20 kHz, 23 kHz, 25 kHz (sound of silence), 30 kHz, 35 kHz, 36 kHz, and 40 kHz.

Can be anodized or as here wolfram carbide coated for even more ware

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!