Principle and advantages of ultrasonic handheld spot welding machine

Ultrasonic handheld spot welding machine actually belongs to the category of ultrasonic welding, which generates high-frequency vibration through ultrasonic waves to weld two materials, metal or plastic. Ultrasonic spot welding is relatively more suitable for machining of thermoformed parts that do not have assembly contours, or parts whose geometry and actual conditions preclude the possibility of standard welding operations.

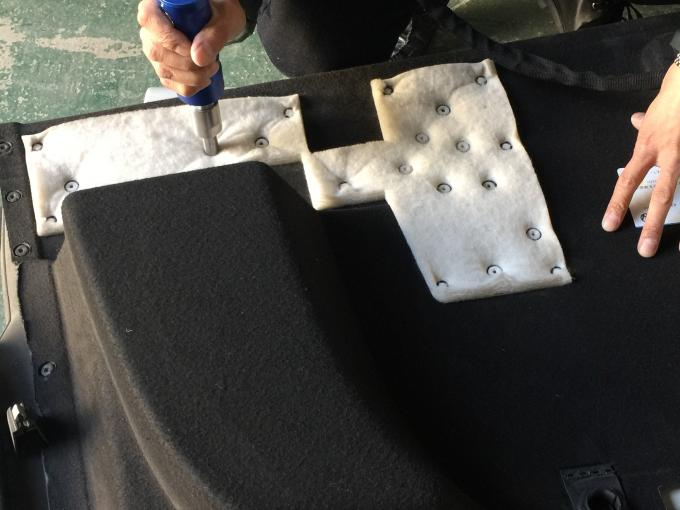

Spot welding can perform ultrasonic strong spot welding on soft plastic sheets such as ABS, polyethylene, polypropylene, PVC, etc. Specially designed projection head is used to enhance welding strength and appearance. Ultrasonic spot welding replaces adhesives, rivets, staples and other mechanical fasteners. The process is used to assemble trailer bodies, car defroster pipes, furniture and other large thermoplastic parts. Using a portable hand tool as well as a multi-head automation system, many welds can be performed simultaneously.

Welding principle

Ultrasound is a mechanical vibration, similar to the vibrations produced by musical instruments. These vibrations are called ultrasound because their frequencies are higher than the human ear can hear (greater than 16 kHz). In acoustic assemblies, these pressure waves are generated by generators. This will send alternating current of the same frequency as the converter (or transducer). A transducer made of piezoelectric ceramics then converts this energy into mechanical vibrations. Mechanical vibrations then generate thermal friction, which excites the molecules of the material being welded into motion. Ultrasonic energy melts the point of contact between the two parts, creating a joint that allows the parts to bond quickly.

The spot welder is suitable for those components that do not need to weld the entire welding path at the same time. It is light in weight and easy to use, and can be used in outdoor scenes. Spot welding machines are highly versatile, flexible and cost-effective, so they remain highly competitive in various welding fields.

Welding advantages

maximize efficiency

Ultrasonic welding is monitored through time, energy, power and height constraints, and the entire welding process is detected in real time, maximizing the efficiency of the entire welding process and minimizing the energy consumption of production.

cost saving and environmental protection

The whole process of welding is clean and pollution-free, because no harmful solvents or adhesives are used in the welding process, and the product itself will not be damaged, avoiding some of the problems of traditional welding and bonding processes and saving welding costs. Due to the complete electrical characteristics, this technology does not require a high level of maintenance.

Speed advantage

Typical welding cycle times are within 0.5 seconds, which is faster than other welding methods. This welding technique is much faster than traditional adhesives or solvents. The cooling time is very fast and the workpiece does not need to be left in the tool for a long time to dry or cure the welded joint.

Easy to operate

The general ultrasonic spot welding equipment is a small machine, which is relatively easy to operate and does not require high manual technology. It is convenient to store after use and does not take up a lot of space. Ergonomic and lightweight handheld probe reduces operator fatigue. A lightweight system with an integrated handle makes the unit easy to move for easy factory movement.

High welding precision

High-precision thrust control and highly accurate welding depth control ensure the overall welding quality and avoid weak welding. Ensure a certain welding quality and avoid the occurrence of black or burning materials.

Equipment composition

Ultrasonic handheld spot welder equipment includes flow control valve, transducer, ultrasonic generator and welding head. Compared with ordinary welding equipment, the spot welding machine is lighter and suitable for welding work that requires transfer scenes.

ultrasonic generator

The generator converts electrical energy from the single-phase power supply to the correct frequency and voltage for the transducer to convert mechanical vibrations. The microprocessor unit controls the welding cycle and feeds back key welding information to the user through the user interface. The user interface also allows the operator to enter the desired welding parameters. The main function of the ultrasonic generator is to convert 50-60 Hz electrical energy (5000 watts) into 20 to 40 kHz high frequency electrical energy. A frequency widely used in ultrasonic welding applications is 20 kHz.

flow control valve

The flow control valve regulates the speed at which the welding head approaches the part being welded. Some equipment manufacturers have introduced electromagnetic force application systems in place of traditional pneumatic cylinders. This allows for better control over the approach speed and can be useful when welding small or delicate parts.

transducer

A transducer, also called a converter, converts electrical energy from a generator into mechanical vibrations for the welding process. It consists of a number of piezoelectric ceramic discs sandwiched between two metal blocks (usually titanium). Between each disc is a thin metal plate that forms the electrodes. When a sinusoidal electrical signal is fed to the transducer through the electrodes, the disk expands and contracts, producing an axial peak-to-peak motion of 15 to 20 μm. Transducers are delicate devices and should be handled with care during the soldering process. Once the element is damaged, the transducer will not function.

horn

The horn reinforcement has two functions, mainly to amplify the mechanical vibration generated at the transducer tip and transmit it to the welding head. The second objective was to provide a location for mounting the stack on the welding press. When the transducer applies ultrasonic energy, the horn expands and contracts. Like other elements in the welding stack, the horn is a tuning device, so it must resonate at a specific frequency in order to transfer ultrasonic energy from the transducer to the welding head. To function successfully, the horn must be half the wavelength of the ultrasonic waves in the material from which they are made, or a multiple of that length. Usually, it is half the wavelength.

Welding head

The welding head is the element in the welding stack that provides energy to the parts to be welded. The design of the welding head is critical to successful welding. The horn is also a tuning device and in most applications it also provides mechanical gain. It is usually made of aluminum or titanium. Aluminum fillets are often used in low-volume applications because the material can cause wear. Some fillets have specially hardened tips to reduce wear during welding. As with horn elements, the length of the fillet must be half the wavelength of the ultrasonic waves in the material from which it is made, or a multiple of that length. This ensures that the fillet end has enough vibration to make the weld. The amplitude is usually between 30 and 120 μm.