loading

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-R35 |

| Minimum Order Quantity | 1pcs |

| Price | Negotiable |

| Packaging Details | Wooden |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 50sets/Month |

| Frequency | 35Khz | Power | 800w |

|---|---|---|---|

| Horn Material | Steel | Horn | Rotary Horn |

| Generator | Digital | Weight | 150kg |

| Package | Wooden | ||

| High Light | 35K Ultrasonic Sewing Machine,Rotary Bonding Ultrasonic Sewing Machine,Rotary Bonding Ultrasonic Sealing Machine | ||

Parameter

| Model | RPS-R35 |

| Frequency | 35KHZ |

| Power | 800W |

| Ceramice chips | 4 chips |

| Running speed | 20m/min in max |

| Welding width | 15mm in max |

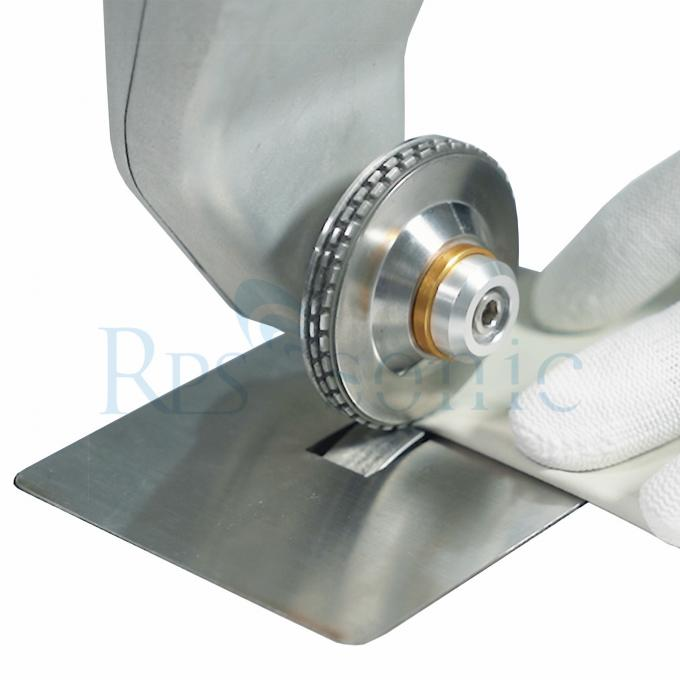

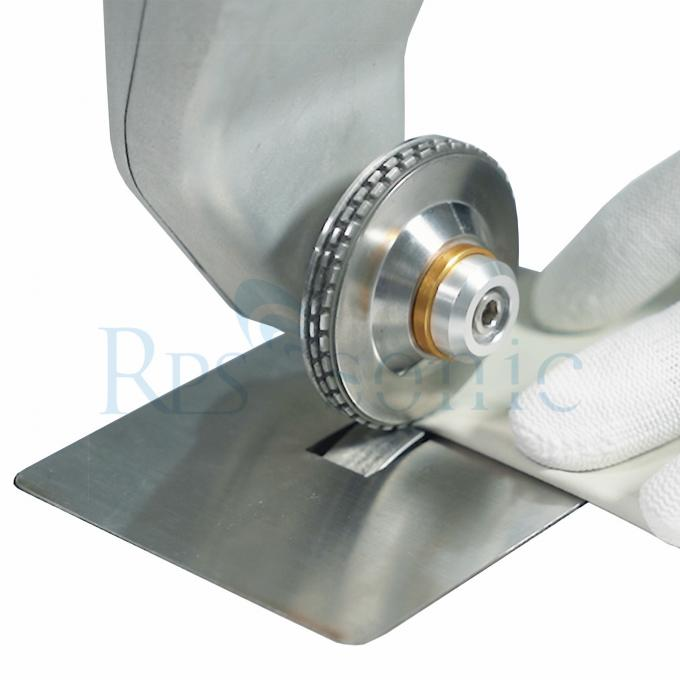

| Welding horn | 35Khz rotary horn |

| Generator | digital generator |

Description

The ultrasonic part of the Ultrasonic sewing machine is divided into two major components: ultrasonic generator and ultrasonic transducer system. Ultrasonic sewing machine is specially designed for sewing of thermoplastic fabrics such as nylon fabric, PVC, PU, TPU fabric and non-woven fabric, completely replace the traditional sewing machine, no need needle and thread.

Equipped with different horn designs, it can be sealing, cutting and sewing.

Ultrasonic welding machines of the RPS-RS series combine all the physical advantages of ultrasonic welding with the whole range of technological sewing experience. On the machine the workpiece is held between the sonotrode and the anvil wheel and welded continuously under pressure. When welding continuously by the ultrasonic method, the material to be welded will be subjected to rapid changing pressure vibrations. The heat develops because of molecular vibrations beneath the material surface, for thin materials within the immediate vicinity of the actual weld.

We have more than 10 years of experience in welding technology. Having started with the welding production of personal protective equipment, we are now specialists in high-tech machine construction and ultrasonic welding components and software development with a huge application spectrum.

RPS-SONIC offers you innovative and state-of-the-art ultrasonic technology. Its reliability and precision stand out and meet the quality demands of tomorrow. With the continuous welding technology and special purpose and customized machinery manufacturing, be find the perfect solution for your business.

Product function

1. Trimming: Single-sided straight or curved cutting, and edge melting treatment, so that the edge is smooth and not rough, without burrs.

2. Stitching: Two or more layers are stitched together, wireless needleless instead of stitching and the welding strength is good, the fabric stitching is tighter, and the product quality is more stable. With continuous processing, automatic feeding, fast speed, high efficiency and uniform quality.

3. Hollowing: cut out various pattern holes and do welding treatment .

4. Strip cutting: single or multiple strips of material can be opened and cut at the same time. And do fusion edge treatment without burrs .

5. Forming: cutting, stitching, and embossing at the same time, so that the product is formed at one time.

Applications

Apply to lace clothing , ribbon , trim , filter , lacing and quilting , decoration products , handkerchief , tablecloth , curtain , bedspread , pillowcase , quily cover , tent , raincoat , disposable operating coat and hat , disposable mask , non-woven fabric bags and so on.

| Frequency | 35Khz | Power | 800w |

|---|---|---|---|

| Horn Material | Steel | Horn | Rotary Horn |

| Generator | Digital | Weight | 150kg |

| Package | Wooden | ||

| High Light | 35K Ultrasonic Sewing Machine,Rotary Bonding Ultrasonic Sewing Machine,Rotary Bonding Ultrasonic Sealing Machine | ||

Parameter

| Model | RPS-R35 |

| Frequency | 35KHZ |

| Power | 800W |

| Ceramice chips | 4 chips |

| Running speed | 20m/min in max |

| Welding width | 15mm in max |

| Welding horn | 35Khz rotary horn |

| Generator | digital generator |

Description

The ultrasonic part of the Ultrasonic sewing machine is divided into two major components: ultrasonic generator and ultrasonic transducer system. Ultrasonic sewing machine is specially designed for sewing of thermoplastic fabrics such as nylon fabric, PVC, PU, TPU fabric and non-woven fabric, completely replace the traditional sewing machine, no need needle and thread.

Equipped with different horn designs, it can be sealing, cutting and sewing.

Ultrasonic welding machines of the RPS-RS series combine all the physical advantages of ultrasonic welding with the whole range of technological sewing experience. On the machine the workpiece is held between the sonotrode and the anvil wheel and welded continuously under pressure. When welding continuously by the ultrasonic method, the material to be welded will be subjected to rapid changing pressure vibrations. The heat develops because of molecular vibrations beneath the material surface, for thin materials within the immediate vicinity of the actual weld.

We have more than 10 years of experience in welding technology. Having started with the welding production of personal protective equipment, we are now specialists in high-tech machine construction and ultrasonic welding components and software development with a huge application spectrum.

RPS-SONIC offers you innovative and state-of-the-art ultrasonic technology. Its reliability and precision stand out and meet the quality demands of tomorrow. With the continuous welding technology and special purpose and customized machinery manufacturing, be find the perfect solution for your business.

Product function

1. Trimming: Single-sided straight or curved cutting, and edge melting treatment, so that the edge is smooth and not rough, without burrs.

2. Stitching: Two or more layers are stitched together, wireless needleless instead of stitching and the welding strength is good, the fabric stitching is tighter, and the product quality is more stable. With continuous processing, automatic feeding, fast speed, high efficiency and uniform quality.

3. Hollowing: cut out various pattern holes and do welding treatment .

4. Strip cutting: single or multiple strips of material can be opened and cut at the same time. And do fusion edge treatment without burrs .

5. Forming: cutting, stitching, and embossing at the same time, so that the product is formed at one time.

Applications

Apply to lace clothing , ribbon , trim , filter , lacing and quilting , decoration products , handkerchief , tablecloth , curtain , bedspread , pillowcase , quily cover , tent , raincoat , disposable operating coat and hat , disposable mask , non-woven fabric bags and so on.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!