Views: 58 Author: Site Editor Publish Time: 2024-03-06 Origin: Site

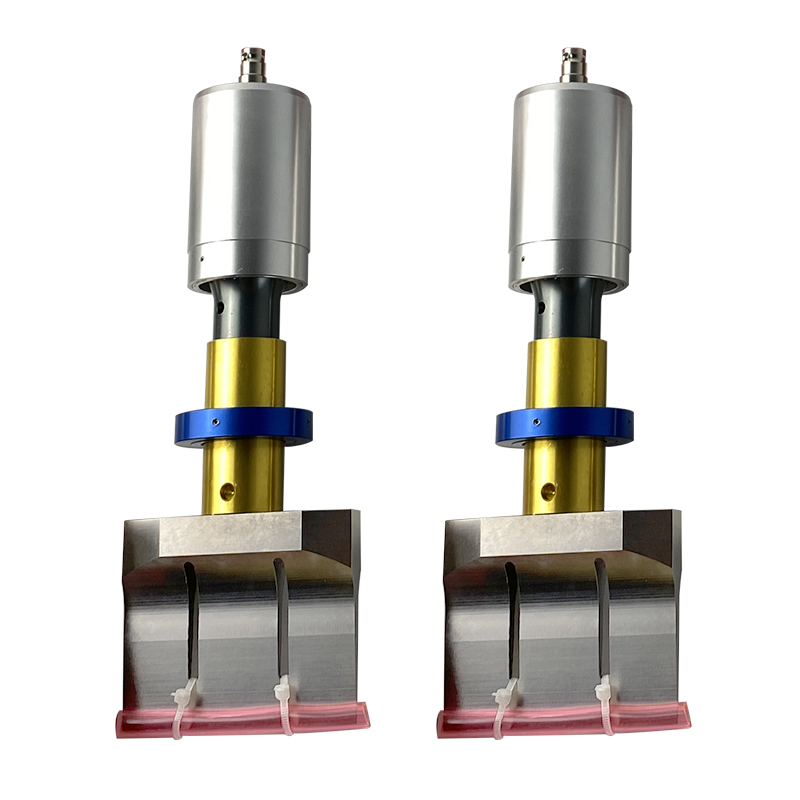

Ultrasonic cutting is a method of cutting materials through high-frequency vibration. It cuts rubber and other materials into smooth, clear and dry shapes without generating heat. The principle of ultrasonic cutting is to convert 50/60Hz current into 20, 30 or 40kHz electrical energy through an ultrasonic generator, and then convert it into mechanical vibration of the same frequency through a transducer. The mechanical vibration then passes through a set of amplitude modulators that can change the amplitude. The device is passed to the cutting knife.

Ultrasonics can easily cut through resin, rubber, plastic, fabric, and a variety of overlapping composites and foods. Ultrasonic cutting technology is increasingly widely used in the field of aviation manufacturing, such as glass fiber, carbon fiber, Kevlar fiber, various honeycomb materials, prepreg fiber materials and various foam materials.

Ultrasonic rubber cutting is a method of cutting materials through high-frequency vibration. It cuts rubber into smooth, clear and dry shapes without generating heat. Compared with traditional mechanical cutting, ultrasonic rubber cutting can better control the cutting angle, thickness and type, thereby increasing cutting speed and quality. Can also easily cut resin, rubber, plastic, fabric, and a variety of overlapping composites and foods.

content is empty!