loading

| Availability: | |

|---|---|

| Quantity: | |

RPS-FC35

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-C40 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 40Khz | Power | 600w |

|---|---|---|---|

| Blade Size | 82.5mm | Blade Material | Titanium |

| Voltage | 220/110V | Weight | 8kg |

| Application | Food,rubber | Generator | Digital |

| High Light | Titanium Horns Ultrasonic Rubber Cutter,PLC Controlled Ultrasonic Rubber Cutter,82.5mm Blade Ultrasonic Cutting Equipment | ||

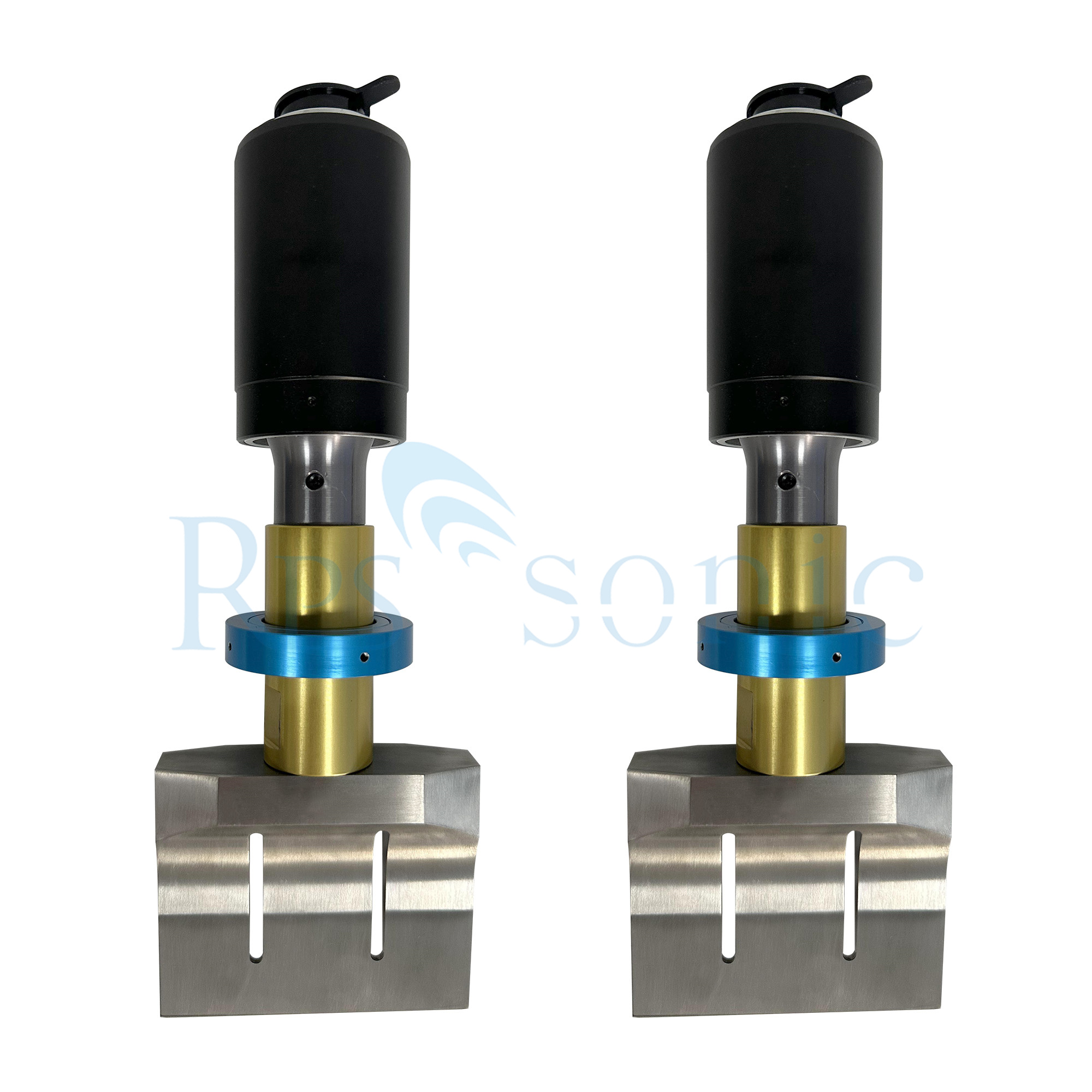

Titanium Horn Ultrasonic Rubber Cutter With 82.5mm Blade RS485 PLC Controlled

S485 communication control Ultrasonic rubber cutting system with 82.5mm blade

Parameter

| Machine | Ultrasonic rubber/cake Cutter |

| Frequency(KHz) | 40KHz |

| Power | 500 W |

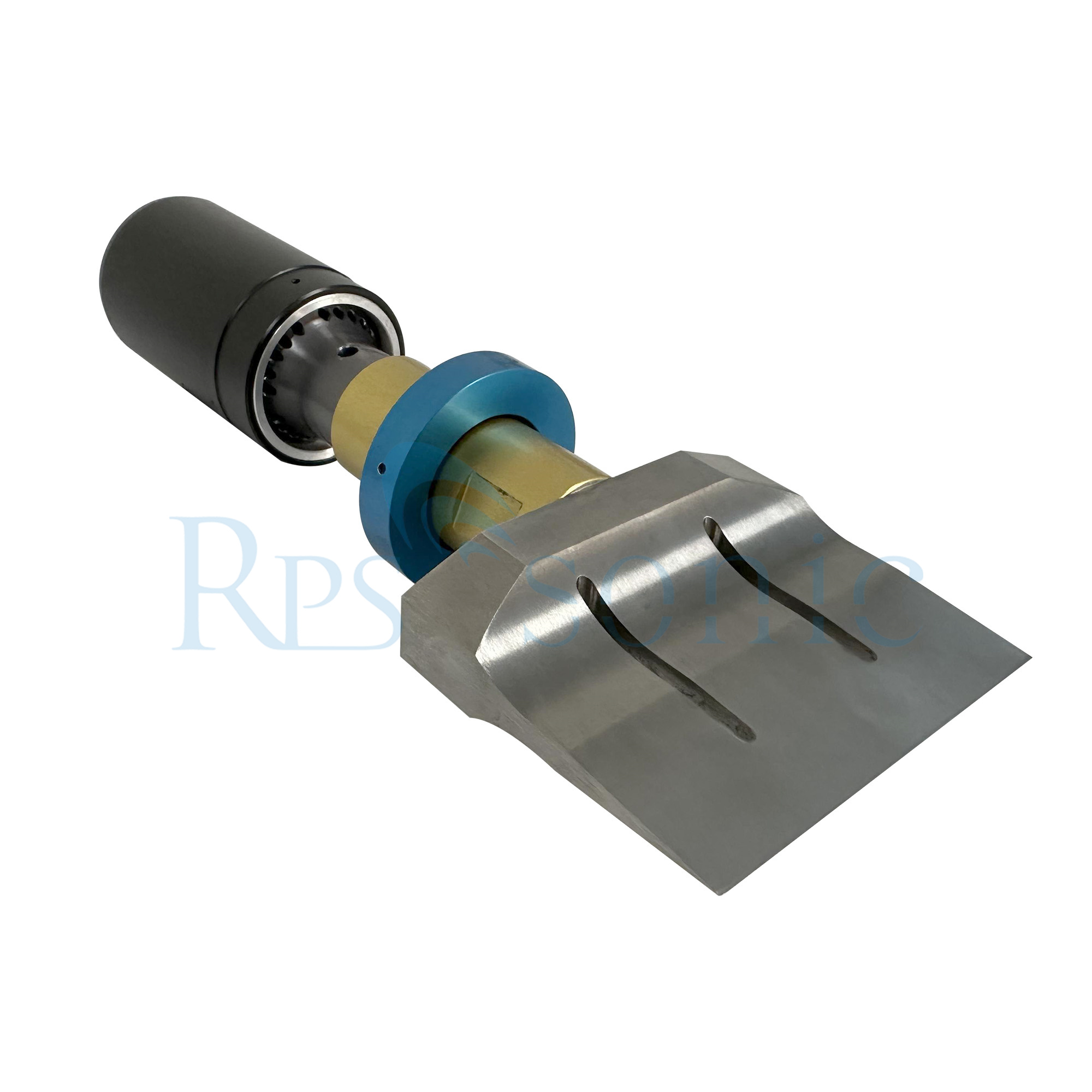

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

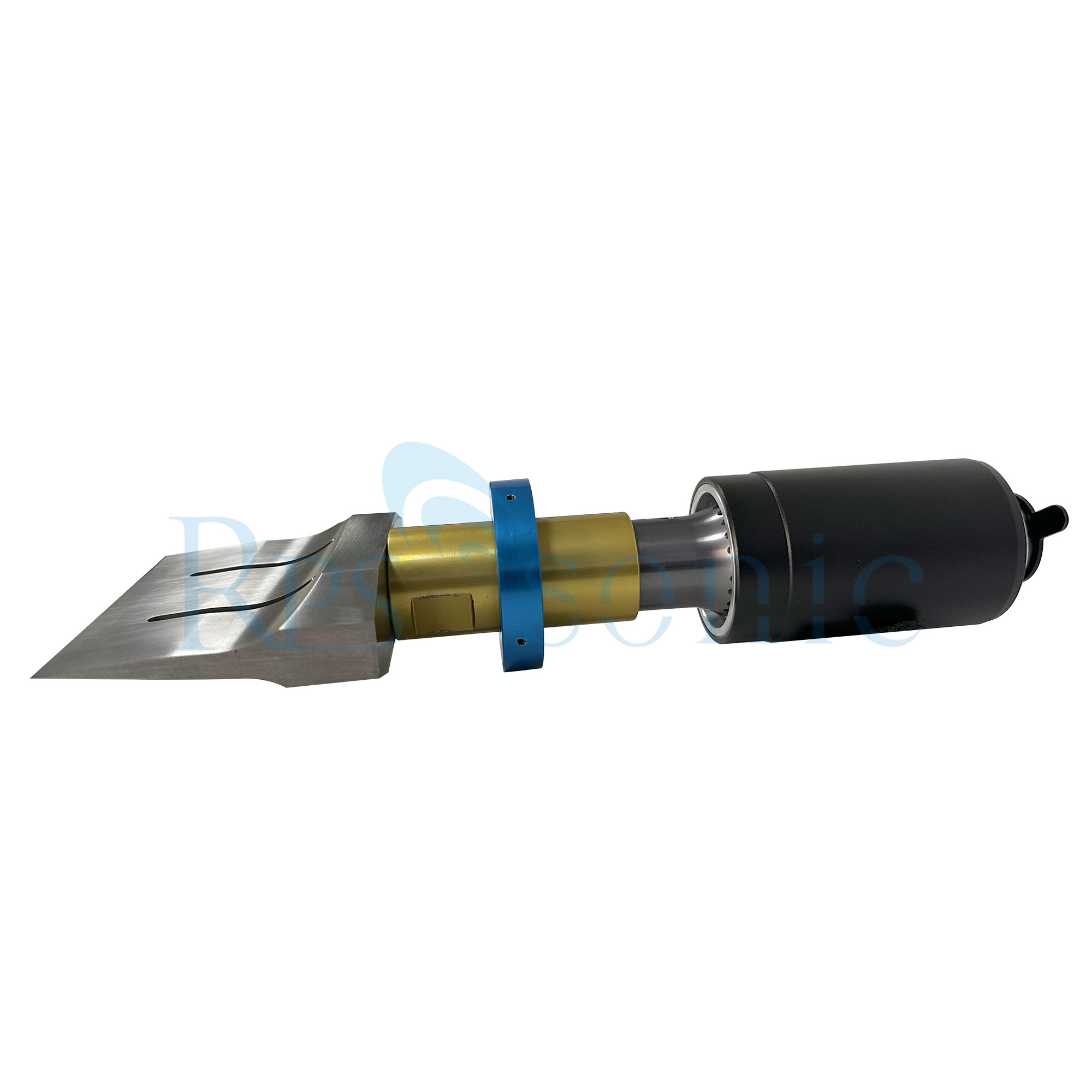

| The width of blade | 82.5mm |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 0.6KG |

Description

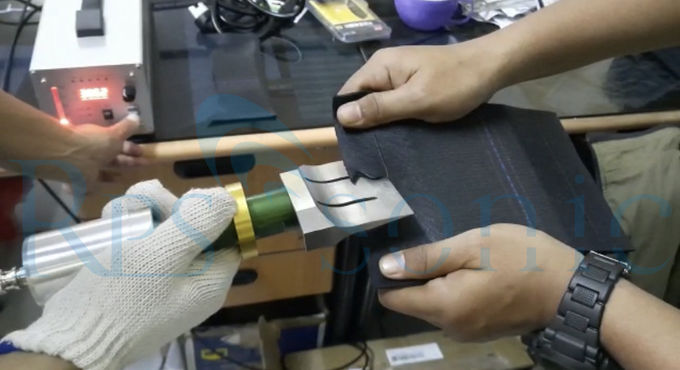

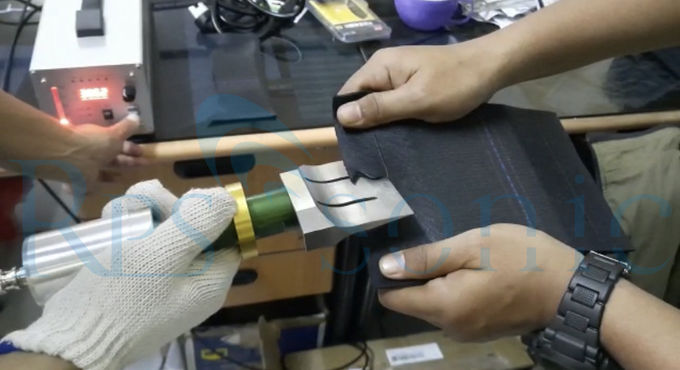

The ultrasonic rubber cutting system is composed of an automatic frequency tracking generator, a high-Q ultrasonic transducer, and a titanium alloy cutting knife. It has a good performance in rubber cutting. The whole machine is simple and convenient to install, real-time frequency tracking, adjustable amplitude, abnormal protection, etc.; it can be controlled by PLC or RS485 communication.

The principle of ultrasonic cutting machine is completely different from traditional pressure cutting. It uses ultrasonic energy to locally heat and melt the material to be cut, so as to achieve the purpose of cutting the material. Therefore, ultrasonic cutting does not require sharp edges, nor does it require great pressure, and does not cause chipping or cracking of the material to be cut. At the same time, since the cutting knife is ultrasonically vibrated, the friction resistance is particularly small, and the cutting material is not easy to adhere to the blade. This is particularly effective for viscous and elastic materials, frozen materials (such as food), rubber materials, and objects that are inconvenient to apply pressure.

We can conduct tests for free and provide a variety of solutions, including production, secondary production, installation of E wiring and optimization of existing production lines.

Ultrasonic cutting uses the energy of sound waves to cut. It does not require sharp cutting edges, and does not require a lot of pressure, and will not cause chipping or damage to the material being cut. Ultrasonic rubber cutter can easily cut resin, rubber, plastic, fabric and various overlapping composite materials and food.

The principle of ultrasonic rubber cutting knife is to convert 50/60Hz current into 20, 30 or 4OkHx electric energy through an ultrasonic generator (also called ultrasonic power supply). The converted high-frequency electric energy is again converted into mechanical vibration of the same frequency through the transducer, and then the mechanical vibration is transmitted to the cutting knife through a set of amplitude modulator devices that can change the amplitude. The ultrasonic rubber cutter vibrates along its length with an amplitude of 10-70μm, repeating 40,000 times (40 kHz) per second (the vibration of the blade is microscopic, which is hard to see with the naked eye). The cutting knife then transfers the received vibration energy to the cutting surface of the workpiece to be cut. In this area, the vibration energy is used to cut the rubber by activating the molecular energy of the rubber and opening the molecular chain.

Features

Intelligent automatic frequency tracking ultrasonic generator, real-time frequency tracking, power, current, and frequency abnormal protection;

20KHz 2000W high-power transducer, low impedance, high conversion efficiency, strong amplitude; special ultrasonic cutting knife, accurate frequency, strong wear resistance;

Titanium alloy horn, low impedance, high transmission efficiency;

The cutting precision is high, and the rubber material is not deformed;

You can choose 20KHz or 40KHz

| Frequency | 40Khz | Power | 600w |

|---|---|---|---|

| Blade Size | 82.5mm | Blade Material | Titanium |

| Voltage | 220/110V | Weight | 8kg |

| Application | Food,rubber | Generator | Digital |

| High Light | Titanium Horns Ultrasonic Rubber Cutter,PLC Controlled Ultrasonic Rubber Cutter,82.5mm Blade Ultrasonic Cutting Equipment | ||

Titanium Horn Ultrasonic Rubber Cutter With 82.5mm Blade RS485 PLC Controlled

S485 communication control Ultrasonic rubber cutting system with 82.5mm blade

Parameter

| Machine | Ultrasonic rubber/cake Cutter |

| Frequency(KHz) | 40KHz |

| Power | 500 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | 82.5mm |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 0.6KG |

Description

The ultrasonic rubber cutting system is composed of an automatic frequency tracking generator, a high-Q ultrasonic transducer, and a titanium alloy cutting knife. It has a good performance in rubber cutting. The whole machine is simple and convenient to install, real-time frequency tracking, adjustable amplitude, abnormal protection, etc.; it can be controlled by PLC or RS485 communication.

The principle of ultrasonic cutting machine is completely different from traditional pressure cutting. It uses ultrasonic energy to locally heat and melt the material to be cut, so as to achieve the purpose of cutting the material. Therefore, ultrasonic cutting does not require sharp edges, nor does it require great pressure, and does not cause chipping or cracking of the material to be cut. At the same time, since the cutting knife is ultrasonically vibrated, the friction resistance is particularly small, and the cutting material is not easy to adhere to the blade. This is particularly effective for viscous and elastic materials, frozen materials (such as food), rubber materials, and objects that are inconvenient to apply pressure.

We can conduct tests for free and provide a variety of solutions, including production, secondary production, installation of E wiring and optimization of existing production lines.

Ultrasonic cutting uses the energy of sound waves to cut. It does not require sharp cutting edges, and does not require a lot of pressure, and will not cause chipping or damage to the material being cut. Ultrasonic rubber cutter can easily cut resin, rubber, plastic, fabric and various overlapping composite materials and food.

The principle of ultrasonic rubber cutting knife is to convert 50/60Hz current into 20, 30 or 4OkHx electric energy through an ultrasonic generator (also called ultrasonic power supply). The converted high-frequency electric energy is again converted into mechanical vibration of the same frequency through the transducer, and then the mechanical vibration is transmitted to the cutting knife through a set of amplitude modulator devices that can change the amplitude. The ultrasonic rubber cutter vibrates along its length with an amplitude of 10-70μm, repeating 40,000 times (40 kHz) per second (the vibration of the blade is microscopic, which is hard to see with the naked eye). The cutting knife then transfers the received vibration energy to the cutting surface of the workpiece to be cut. In this area, the vibration energy is used to cut the rubber by activating the molecular energy of the rubber and opening the molecular chain.

Features

Intelligent automatic frequency tracking ultrasonic generator, real-time frequency tracking, power, current, and frequency abnormal protection;

20KHz 2000W high-power transducer, low impedance, high conversion efficiency, strong amplitude; special ultrasonic cutting knife, accurate frequency, strong wear resistance;

Titanium alloy horn, low impedance, high transmission efficiency;

The cutting precision is high, and the rubber material is not deformed;

You can choose 20KHz or 40KHz

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment