loading

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-R8 |

| Minimum Order Quantity | 1pcs |

| Price | Negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 500w |

|---|---|---|---|

| Size | Customized | Weight | 15kg |

| Generator | Digital | ||

| High Light | 1200w Ultrasonic Milling Equipment,20Khz Ultrasonic Milling Equipment,Digital Generator Ultrasonic Milling Equipment | ||

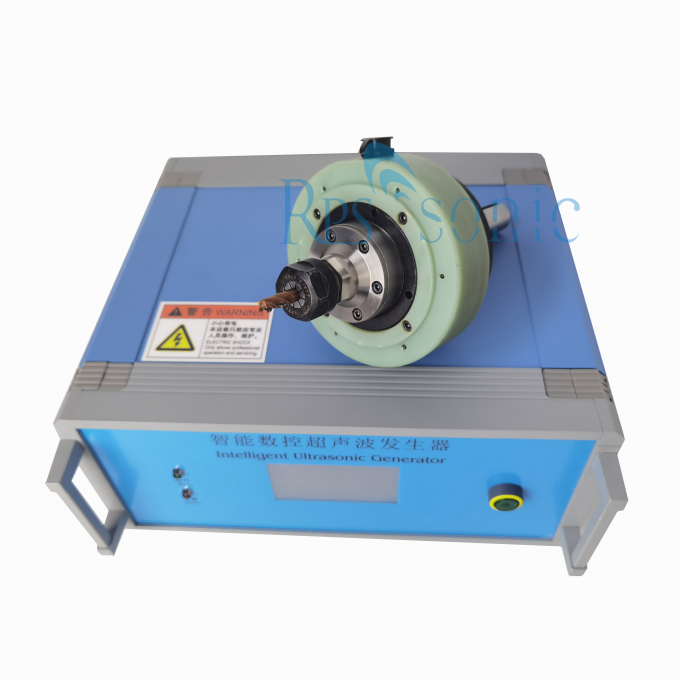

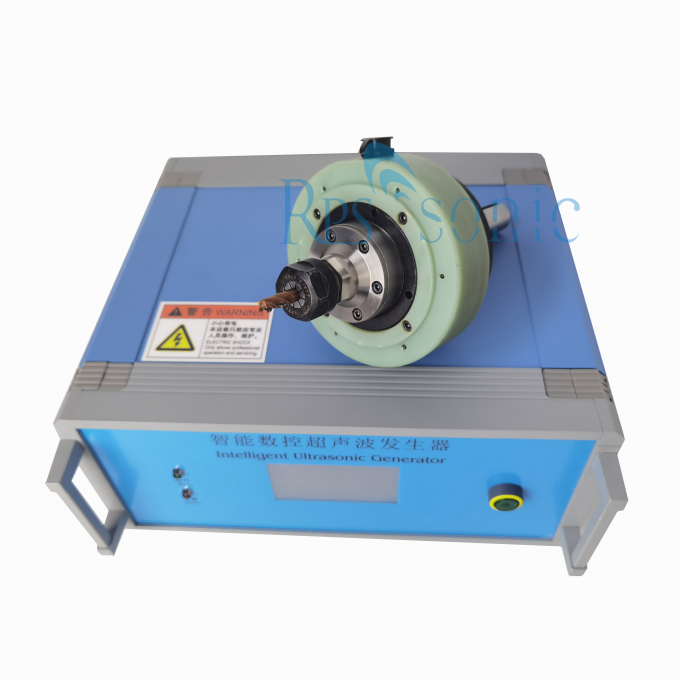

20Khz 1200w Ultrasonic Milling Rotary Machining Auxiliary Machining With Digital Generator

20Khz Ultrasonic milling equipment R8 handle Auxiliary processing

Parameter

| Item | Parameter |

| Abrasive | Boron carbide, aluminium oxide and silicon carbide |

| Grit size(d0) | 100 – 800 |

| Frequency of vibration (f) | 19 – 25 kHz |

| Amplitude of vibration (a) | 15 - 50 µm |

| Tool material | Soft steel titanium alloy |

| Wear ratio | Tungsten 1.5:1 and glass 100:1 |

| Gap overcut | 0.02-0.1 mm |

Description

Ultrasonic Milling Rotary Machining Auxiliary Machining Ultrasonic Machining Ultrasonic turning is microscopically a kind of pulse milling. In a vibration cycle, the effective milling time of the tool is very short, and the tool is completely separated from the workpiece and chips in more than 80% of the time. The tool is in intermittent contact with the workpiece and chips, which makes the friction on the tool smaller, the heat generated is greatly reduced, and the milling force is significantly reduced, avoiding the phenomenon of "knife yielding" in ordinary milling, and does not produce built-up edge . Using this kind of ultrasonic milling, precision machining can be performed on ordinary machine tools. The shape and position tolerances such as roundness, cylindricity, flatness, parallelism, and straightness mainly depend on the accuracy of the machine tool spindle and guide rail, which can reach close to zero error. It is possible to replace grinding with turning, reaming with drilling, and grinding with milling. Compared with high-speed hard milling, it does not require high machine rigidity and does not destroy the metallographic structure of the workpiece surface. In the finishing of curved contour parts, CNC lathes, machining centers, etc. can be used for profiling processing, which can save the high purchase cost of CNC grinding machines. Hangzhou Shenghui ultrasonic turning and ultrasonic rotary milling are widely used in mechanical processing.

Advantage

1. The ultrasonic milling force is small, about 1/3-1/10 of the milling force of ordinary tools.

2. Ultrasonic turning has high machining accuracy, which mainly depends on the accuracy of the machine tool used. The shape and position tolerance of the processed workpiece is almost close to the relative accuracy of the machine tool.

3. The temperature of ultrasonic milling is low, and the workpiece is kept at room temperature.

4. There is no built-up edge, the workpiece deformation is small, and there is no burr.

5. The surface roughness of ultrasonic milling is low, which can be close to the theoretical roughness value and can reach below Ra0.2.

6. The "rigidization" of the ultrasonically machined parts, that is, compared with ordinary milling, is equivalent to an increase in the rigidity of the workpiece.

7. The ultrasonic machining process is stable and can effectively eliminate flutter.

8. The cooling and lubricating effects of ultrasonic milling fluid are improved.

9. The tool durability is increased several times to dozens of times.

10. The ultrasonically machined surface is in a state of compressive stress, and the fatigue strength, wear resistance and corrosion resistance of the parts are improved.

Application

Because ultrasonic milling has so many advantages, it can be widely used in milling of various difficult-to-machine materials in aviation, aerospace, military and other fields.

1. Milling of difficult-to-machine materials: such as heat-resistant steel, titanium alloy, constant elasticity alloy, high-temperature alloy, stainless steel, chilled cast iron, engineering ceramics, composite materials and granite, etc.

2. Ultrasonic machining of hardened steel parts and superhard parts can obtain high machining accuracy and surface quality: hardened steel parts with hardness above HRC60 can be easily ultrasonically machined with cemented carbide tools, such as high-speed steel, Bearing steel, etc.; machining carbide with PCD tools can greatly improve the durability of the tool

3. Forming milling: use forming milling tools to process various types of contour surfaces, inner and outer spherical surfaces, excessive arcs, conical surfaces, etc.

4. Ultrasonic turning of slender rods and thin-walled parts

5. Ultrasonic turning of ultra-fine diameter parts

6. Ultra-precision ultrasonic machining

11. The surface of the workpiece after ultrasonic turning has a rainbow effect.

| Frequency | 20Khz | Power | 500w |

|---|---|---|---|

| Size | Customized | Weight | 15kg |

| Generator | Digital | ||

| High Light | 1200w Ultrasonic Milling Equipment,20Khz Ultrasonic Milling Equipment,Digital Generator Ultrasonic Milling Equipment | ||

20Khz 1200w Ultrasonic Milling Rotary Machining Auxiliary Machining With Digital Generator

20Khz Ultrasonic milling equipment R8 handle Auxiliary processing

Parameter

| Item | Parameter |

| Abrasive | Boron carbide, aluminium oxide and silicon carbide |

| Grit size(d0) | 100 – 800 |

| Frequency of vibration (f) | 19 – 25 kHz |

| Amplitude of vibration (a) | 15 - 50 µm |

| Tool material | Soft steel titanium alloy |

| Wear ratio | Tungsten 1.5:1 and glass 100:1 |

| Gap overcut | 0.02-0.1 mm |

Description

Ultrasonic Milling Rotary Machining Auxiliary Machining Ultrasonic Machining Ultrasonic turning is microscopically a kind of pulse milling. In a vibration cycle, the effective milling time of the tool is very short, and the tool is completely separated from the workpiece and chips in more than 80% of the time. The tool is in intermittent contact with the workpiece and chips, which makes the friction on the tool smaller, the heat generated is greatly reduced, and the milling force is significantly reduced, avoiding the phenomenon of "knife yielding" in ordinary milling, and does not produce built-up edge . Using this kind of ultrasonic milling, precision machining can be performed on ordinary machine tools. The shape and position tolerances such as roundness, cylindricity, flatness, parallelism, and straightness mainly depend on the accuracy of the machine tool spindle and guide rail, which can reach close to zero error. It is possible to replace grinding with turning, reaming with drilling, and grinding with milling. Compared with high-speed hard milling, it does not require high machine rigidity and does not destroy the metallographic structure of the workpiece surface. In the finishing of curved contour parts, CNC lathes, machining centers, etc. can be used for profiling processing, which can save the high purchase cost of CNC grinding machines. Hangzhou Shenghui ultrasonic turning and ultrasonic rotary milling are widely used in mechanical processing.

Advantage

1. The ultrasonic milling force is small, about 1/3-1/10 of the milling force of ordinary tools.

2. Ultrasonic turning has high machining accuracy, which mainly depends on the accuracy of the machine tool used. The shape and position tolerance of the processed workpiece is almost close to the relative accuracy of the machine tool.

3. The temperature of ultrasonic milling is low, and the workpiece is kept at room temperature.

4. There is no built-up edge, the workpiece deformation is small, and there is no burr.

5. The surface roughness of ultrasonic milling is low, which can be close to the theoretical roughness value and can reach below Ra0.2.

6. The "rigidization" of the ultrasonically machined parts, that is, compared with ordinary milling, is equivalent to an increase in the rigidity of the workpiece.

7. The ultrasonic machining process is stable and can effectively eliminate flutter.

8. The cooling and lubricating effects of ultrasonic milling fluid are improved.

9. The tool durability is increased several times to dozens of times.

10. The ultrasonically machined surface is in a state of compressive stress, and the fatigue strength, wear resistance and corrosion resistance of the parts are improved.

Application

Because ultrasonic milling has so many advantages, it can be widely used in milling of various difficult-to-machine materials in aviation, aerospace, military and other fields.

1. Milling of difficult-to-machine materials: such as heat-resistant steel, titanium alloy, constant elasticity alloy, high-temperature alloy, stainless steel, chilled cast iron, engineering ceramics, composite materials and granite, etc.

2. Ultrasonic machining of hardened steel parts and superhard parts can obtain high machining accuracy and surface quality: hardened steel parts with hardness above HRC60 can be easily ultrasonically machined with cemented carbide tools, such as high-speed steel, Bearing steel, etc.; machining carbide with PCD tools can greatly improve the durability of the tool

3. Forming milling: use forming milling tools to process various types of contour surfaces, inner and outer spherical surfaces, excessive arcs, conical surfaces, etc.

4. Ultrasonic turning of slender rods and thin-walled parts

5. Ultrasonic turning of ultra-fine diameter parts

6. Ultra-precision ultrasonic machining

11. The surface of the workpiece after ultrasonic turning has a rainbow effect.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!