loading

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-SONO28 |

| Minimum Order Quantity | 1pcs |

| Price | Negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 28Khz | Power | 600w |

|---|---|---|---|

| Generator | Digital | Horn Material | Titanium Alloy |

| Type | Can Be Customized | Reactor | Glass |

| Weight | 8kg | ||

| High Light | 28Khz ultrasonic degassing equipment,600w ultrasonic degassing equipment,ultrasonic degassing equipment with probe | ||

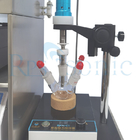

Customized 28Khz 600w ultrasonic degassing equipment with ultrasonic probe

Parameter

| Frequency | 28Khz |

| Frequency adjustment | Auto-tracking type |

| Max. power output6 | 00W |

| Power output | Infinitive adjustment |

| Power supply | AC220V-240V 50/60Hz |

| Amplitude | 0.1-99.9% |

| Temperature control | -20~100℃ |

| Horn size | 2-8mm |

Description

Ultrasonic defoaming and degassing is an application of ultrasonic sonochemical treatment. It uses the "cavitation" effect of ultrasonic waves in liquids to discharge the bubbles in the liquid and improve the quality of the solution.

Ultrasonic waves propagate from the acoustic emitter into the liquid medium, generating alternating positive and negative pressure phases. In the negative pressure (thinning) stage, sufficiently high-intensity ultrasonic waves can overcome the intermolecular adhesion and generate a large number of near-vacuum microbubbles in the liquid. As the bubbles dance in the ultrasonic field, they accelerate each other and merge to form larger bubbles. This process proceeds rapidly until the bubble achieves sufficient buoyancy to float on top of the liquid and release the previously trapped gas into the environment. Acoustic streaming (a steady stream of fluid driven by high-amplitude ultrasonic waves away from the acoustic emitter) can be used to aid in the ascent of gas bubbles, which is especially helpful for degassing highly viscous liquids.

Foaming of beer

Beer needs to be foamed during the process of filling the bottle. If the empty space in the bottle is not occupied by carbon dioxide, the wine will be oxidized into acetaldehyde, which will make the beer unpalatable during storage. In the past, after the beer was poured into the bottle, the bottle was placed on a beating device, and the bottle was beaten one by one for foaming. Each batch processed hundreds of bottles, and the production efficiency was very low. Moreover, there would be noise when beating the bottle , the bottle will also be in danger of being broken. Now someone has conducted research on ultrasonic foaming. When the ultrasonic wave is irradiated on the beer from the outside of the bottle, the foaming will proceed rapidly. If the cap is added immediately, the quality of the beer will be uniform and the bottle will be less damaged. Beer companies in various countries are now conducting research on ultrasonic power, frequency, irradiation methods, etc., and making them practical.

Degassing of cool drinking water

When soda is bottled, whether the lid is tightly closed was previously checked by heating. Because the bottle with a loose lid will foam violently when heated, and defective products can be picked out based on this. In a factory with a large production volume, the use of this heating method is not beneficial in terms of efficiency, economy, or the area occupied by the equipment. Ultrasonic methods can be used. Good test results, the bottle filled with soda and capped is conveyed by a conveyor belt. When the ultrasonic wave is irradiated from the bottom of the bottle, the inside of the bottle will foam, and the air pressure in the empty space and the liquid will reach an equilibrium state. Then when the bottle is irradiated with ultrasonic waves for the second time in another place, the quality of the product can be distinguished according to whether it foams. Along with degassing and defoaming, ultrasonic waves can simultaneously produce deodorizing effects. For example, when ultrasonic waves irradiate soy sauce with a strong amino acid odor, its odor disappears. This is because the odor components enter the bubbles generated by cavitation from the soy sauce, and are discharged out of the liquid as the bubbles rise.

The importance of defoaming and degassing technology in the food industry

1. Degassing is an important operation in the food industry. Degassing can not only avoid the oxidation loss of food nutrients caused by oxygen in the air, but also facilitate subsequent sterilization. Juice processing, degassing can reduce or avoid the oxidation of juice components, and reduce the change of juice color and flavor;

2. The degassing of the cans prevents the expansion of the gas and contents in the cans and damages the cans during heat sterilization;

3.Prevent corrosion of the inner wall of the tank during storage;

4. Prevent changes in the color and fragrance of the contents and the destruction of microorganisms and other nutrients;

5. Prevent the development and growth of aerobic microorganisms;

6. Vacuum degassing is helpful to seal the bottle cap of bottled cans and prevent the caps from jumping off during heating; it can be used as a reference for judging whether the contents of cans are normal

| Frequency | 28Khz | Power | 600w |

|---|---|---|---|

| Generator | Digital | Horn Material | Titanium Alloy |

| Type | Can Be Customized | Reactor | Glass |

| Weight | 8kg | ||

| High Light | 28Khz ultrasonic degassing equipment,600w ultrasonic degassing equipment,ultrasonic degassing equipment with probe | ||

Customized 28Khz 600w ultrasonic degassing equipment with ultrasonic probe

Parameter

| Frequency | 28Khz |

| Frequency adjustment | Auto-tracking type |

| Max. power output6 | 00W |

| Power output | Infinitive adjustment |

| Power supply | AC220V-240V 50/60Hz |

| Amplitude | 0.1-99.9% |

| Temperature control | -20~100℃ |

| Horn size | 2-8mm |

Description

Ultrasonic defoaming and degassing is an application of ultrasonic sonochemical treatment. It uses the "cavitation" effect of ultrasonic waves in liquids to discharge the bubbles in the liquid and improve the quality of the solution.

Ultrasonic waves propagate from the acoustic emitter into the liquid medium, generating alternating positive and negative pressure phases. In the negative pressure (thinning) stage, sufficiently high-intensity ultrasonic waves can overcome the intermolecular adhesion and generate a large number of near-vacuum microbubbles in the liquid. As the bubbles dance in the ultrasonic field, they accelerate each other and merge to form larger bubbles. This process proceeds rapidly until the bubble achieves sufficient buoyancy to float on top of the liquid and release the previously trapped gas into the environment. Acoustic streaming (a steady stream of fluid driven by high-amplitude ultrasonic waves away from the acoustic emitter) can be used to aid in the ascent of gas bubbles, which is especially helpful for degassing highly viscous liquids.

Foaming of beer

Beer needs to be foamed during the process of filling the bottle. If the empty space in the bottle is not occupied by carbon dioxide, the wine will be oxidized into acetaldehyde, which will make the beer unpalatable during storage. In the past, after the beer was poured into the bottle, the bottle was placed on a beating device, and the bottle was beaten one by one for foaming. Each batch processed hundreds of bottles, and the production efficiency was very low. Moreover, there would be noise when beating the bottle , the bottle will also be in danger of being broken. Now someone has conducted research on ultrasonic foaming. When the ultrasonic wave is irradiated on the beer from the outside of the bottle, the foaming will proceed rapidly. If the cap is added immediately, the quality of the beer will be uniform and the bottle will be less damaged. Beer companies in various countries are now conducting research on ultrasonic power, frequency, irradiation methods, etc., and making them practical.

Degassing of cool drinking water

When soda is bottled, whether the lid is tightly closed was previously checked by heating. Because the bottle with a loose lid will foam violently when heated, and defective products can be picked out based on this. In a factory with a large production volume, the use of this heating method is not beneficial in terms of efficiency, economy, or the area occupied by the equipment. Ultrasonic methods can be used. Good test results, the bottle filled with soda and capped is conveyed by a conveyor belt. When the ultrasonic wave is irradiated from the bottom of the bottle, the inside of the bottle will foam, and the air pressure in the empty space and the liquid will reach an equilibrium state. Then when the bottle is irradiated with ultrasonic waves for the second time in another place, the quality of the product can be distinguished according to whether it foams. Along with degassing and defoaming, ultrasonic waves can simultaneously produce deodorizing effects. For example, when ultrasonic waves irradiate soy sauce with a strong amino acid odor, its odor disappears. This is because the odor components enter the bubbles generated by cavitation from the soy sauce, and are discharged out of the liquid as the bubbles rise.

The importance of defoaming and degassing technology in the food industry

1. Degassing is an important operation in the food industry. Degassing can not only avoid the oxidation loss of food nutrients caused by oxygen in the air, but also facilitate subsequent sterilization. Juice processing, degassing can reduce or avoid the oxidation of juice components, and reduce the change of juice color and flavor;

2. The degassing of the cans prevents the expansion of the gas and contents in the cans and damages the cans during heat sterilization;

3.Prevent corrosion of the inner wall of the tank during storage;

4. Prevent changes in the color and fragrance of the contents and the destruction of microorganisms and other nutrients;

5. Prevent the development and growth of aerobic microorganisms;

6. Vacuum degassing is helpful to seal the bottle cap of bottled cans and prevent the caps from jumping off during heating; it can be used as a reference for judging whether the contents of cans are normal

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!