Ultrasonic Coating Systems for Fuel Cell Catalyst Coatings

Ultrasonic spraying has become an industry standard for wave soldering flux coating, which can replace traditional air spraying and foam coating methods, providing a high precision, high performance, low VOCs emission flux coating solution. Dongfang Jinrong provides a complete solution of ultrasonic atomization spraying of flux including ultrasonic nozzle, ultrasonic control, metering liquid supply, etc., which can be used for large-area frontal coating and selective spraying in special areas, and can be convenient and fast. for direct insertion into existing wave soldering systems. Ultrasonic spraying is compatible with all types of flux, reducing flux waste by 80%, covering evenly and fully, and maintaining low maintenance costs.

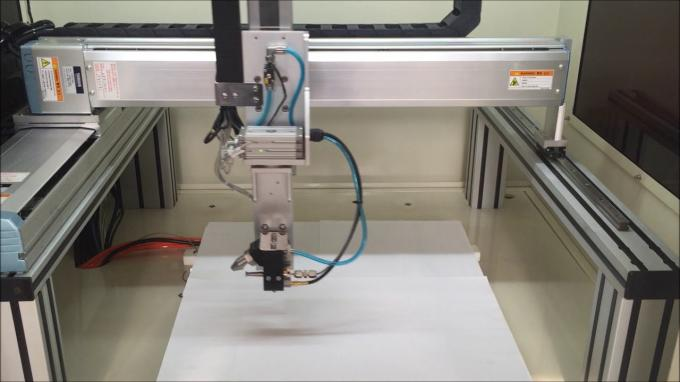

Ultrasonic coating technology has replaced conventional coating systems in a wide range of industrial and R&D applications, and enabled spray processes that would otherwise be impossible. Compared to many other coating systems, ultrasonic spray nozzles are more precise, more controllable, more repeatable, and more environmentally friendly.

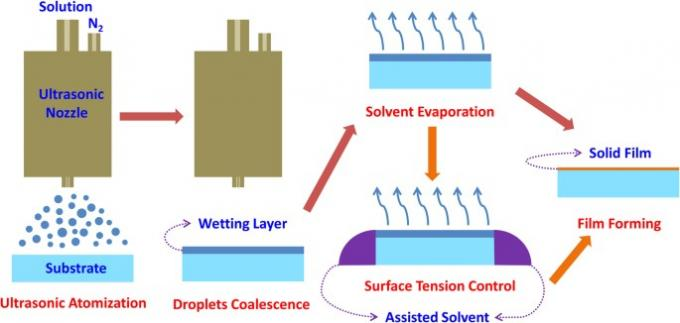

The unpressurized, low-velocity spray is easily controlled and significantly reduces the amount of overspray since the drops settle on the substrate, rather than bouncing off it. This translates into substantial material savings and reduction in emissions into the environment.

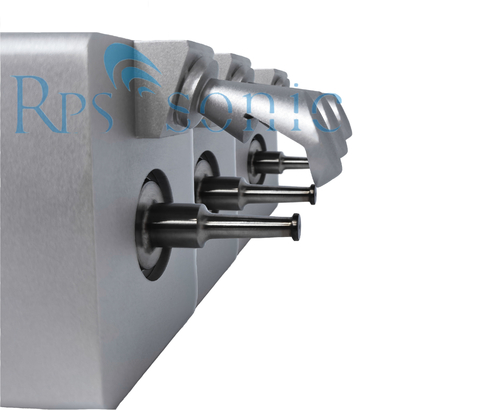

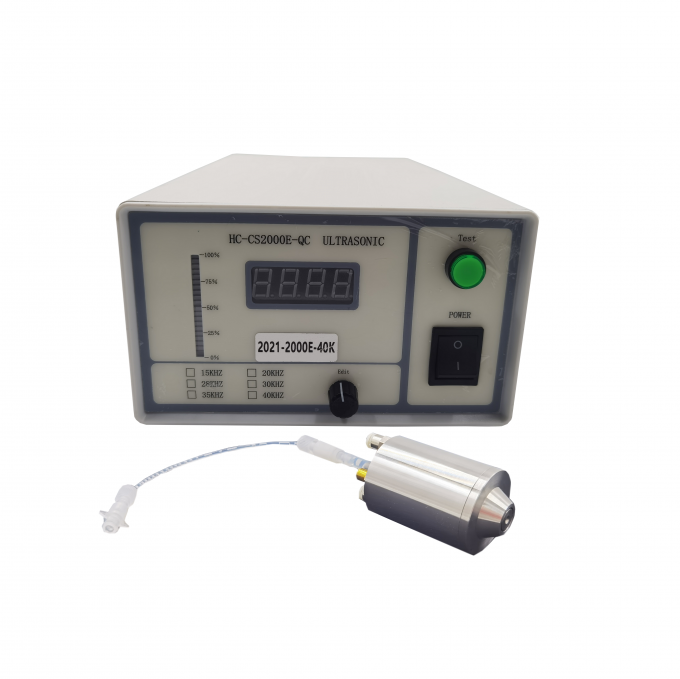

The nozzles are inherently non-clogging, self-cleaning devices due to continuous ultrasonic vibrations and their relatively large orifice. RPS-SONIC's ultrasonic spray nozzles are fabricated from titanium for long life and excellent acoustical properties.

Ultrasonic nozzles open up a broad range of new application possibilities. The nozzles are ideal, for example, when extremely low flow rates are required. And they offer unique benefits when spraying particles in suspension, keeping particles evenly suspended during the entire spray process through the ultrasonic action of the nozzle itself. This results in more uniform dispersion of functional particles in thinner layers.

Ultrasonic Spray Coating Benefits:

- Reduced material consumption and overspray by up to 80%

- Highly controllable spray patterns for reliable, consistent results

- Corrosion-resistant construction

- Ultra-low flow rate capabilities

- Low maintenance non-clogging design

- Reduced downtime in critical manufacturing processes

- High reliability with no moving parts

- Ability to control atomized drop size by choice of nozzle frequency

- Tight drop distribution allows for optimization to desired coating morphology

The gathered ultrasonic nozzle is an ultrasonic atomizing nozzle with a small spray width. It adopts ultrasonic atomizing nozzle technology, and the special constricted flow channel design uniformly gathers and distributes the carrier gas, so that the liquid mist after ultrasonic atomization is ejected in a focused form, thereby reducing the spraying area of the ultrasonic nozzle. Due to the small spray width of the convergent ultrasonic nozzle, it is mainly suitable for various small and medium-sized spraying applications. Complementary with the RPS-SONIC wide spray ultrasonic nozzle, it can almost meet the requirements of all different plane spraying.

The typical application is fuel cell spraying, that is, the membrane electrode spraying in the proton exchange membrane fuel cell. The catalyst (such as platinum-carbon catalyst) dispersion is ultrasonically atomized and sprayed onto the proton exchange membrane to form a uniform and dense membrane electrode. Because the gathered ultrasonic spray nozzle has the advantage of concentrated spraying and can be precisely sprayed in a small area, the gathered ultrasonic atomizing nozzle can also be applied to the surface spraying of interventional medical devices such as drug balloon spraying and drug stent spraying. Dissolve drugs such as rapamycin, paclitaxel, etc. in an organic solvent to prepare a drug solution, and spray the balloon or stent evenly after ultrasonic atomization by a convergent ultrasonic nozzle to form a uniform and dense drug on the surface of the balloon catheter and stent coating. In addition, the gathered ultrasonic nozzle can also be applied to such as thin film solar cell spraying, perovskite solar cell spraying, PCB flux spraying and so on.