loading

| Availability: | |

|---|---|

| Quantity: | |

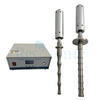

RPS-SONO20

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-S20-2000 |

| Minimum Order Quantity | 1set |

| Price | negotiation |

| Packaging Details | Foam And Wood Box |

| Delivery Time | 3days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 200 sets per month |

Description

Ultrasonic power and cavitation are the top considerations when batch dispersing larger samples of nanoparticles in an ultrasonic cleaner. In this application the tank of the ultrasonic unit is filled with water treated with a surfactant to increase the efficiency of cavitation action. Nanoparticles such as single wall nanotubes (SWNT) are placed in vials containing a solution formulated to stabilize the dispersion. The vials are then fitted into holding devices and lowered into the ultrasonic cleaner solution. Only a portion of the vials must be immersed.

For example, multiple glass vials containing SWNT powders and a suitable solution can be immersed in an ultrasonic bath such as the powerful Elmasonic P30H available from Tovatech. This dual frequency unit operates at a user-selected 37 or 80 kHz and operates at 120 watts of power. For dispersing SWNT it is set to cavitate at the more vigorous 37 kHz, and allows operators to activate its pulse function that increases the power some 20%. This is sufficient power to disperse the SWNT as cavitation action passes from the bath solution through the vial walls and into the SWNT suspension. It is important to keep the bath cool, which can be accomplished by periodically refilling it with ice cold water and by using a cooling coil. At the end of the ultrasonic operation the samples are further processed according to established procedures.

Application fields

1. Pharmaceutical industry

Drug dispersion and emulsification: Ultrasonic homogenizer can disperse insoluble components (such as oily drugs) in drugs into nano-scale particles to increase the bioavailability of drugs.

Vaccines and biological products: Homogenize vaccines, antibodies and other biological products to improve their uniformity and stability.

2. Food industry:

Emulsification and dispersion: For example, in the production of salad dressings, creams, beverages and other foods, it is necessary to emulsify the oil and water phases or disperse solid particles in liquids.

Juice and beverages: Help pulp, fruit particles, etc. to be evenly distributed in beverages to prevent precipitation.

3. Cosmetics industry:

Lotions and creams: Ultrasonic homogenizers can help effectively emulsify oil and water components and improve the stability and texture of products.

Essence and perfume: Used to disperse essential oils, spices and other active ingredients to ensure the uniformity of products.

4. Chemical industry:

Homogenization of polymers: When used to synthesize polymer materials, it can evenly disperse monomers and improve the effect of polymerization reactions.

Pigment dispersion: In chemical products such as coatings and paints, ultrasonic homogenization can effectively disperse pigments and prevent precipitation.

5. Environmental protection:

Wastewater treatment: It can be used to disperse chemical agents in sewage, promote reactions, and improve sewage treatment efficiency.

6. Nanotechnology:

Nanomaterial preparation: It is widely used in the preparation and dispersion of nanomedicines, nanomaterials, nanoemulsions, etc.

| Item | RPS-S500 | RPS-S1000 | RPS-S1500 | RPS-S2000 | RPS-S3000 |

| Working frequency | 20kHz | 20kHz | 20kHz | 20kHz | 20kHz |

| Max power | 500W | 1000W | 1500W | 2000W | 3000W |

| Handing capacity | 0.5 to 2L/min | 0.5 to 3L/min | 0.5 to 4L/min | 1.0 to 6L/min | 1.0 to 8L/min |

| Apply | Production line, be used in combination | ||||

| Reaction tank | 10L,15L,20L,35L,stainless steel | ||||

| Working pressure | Max:5MPa | ||||

| Working temperature | Max: 350°C | ||||

Description

Ultrasonic power and cavitation are the top considerations when batch dispersing larger samples of nanoparticles in an ultrasonic cleaner. In this application the tank of the ultrasonic unit is filled with water treated with a surfactant to increase the efficiency of cavitation action. Nanoparticles such as single wall nanotubes (SWNT) are placed in vials containing a solution formulated to stabilize the dispersion. The vials are then fitted into holding devices and lowered into the ultrasonic cleaner solution. Only a portion of the vials must be immersed.

For example, multiple glass vials containing SWNT powders and a suitable solution can be immersed in an ultrasonic bath such as the powerful Elmasonic P30H available from Tovatech. This dual frequency unit operates at a user-selected 37 or 80 kHz and operates at 120 watts of power. For dispersing SWNT it is set to cavitate at the more vigorous 37 kHz, and allows operators to activate its pulse function that increases the power some 20%. This is sufficient power to disperse the SWNT as cavitation action passes from the bath solution through the vial walls and into the SWNT suspension. It is important to keep the bath cool, which can be accomplished by periodically refilling it with ice cold water and by using a cooling coil. At the end of the ultrasonic operation the samples are further processed according to established procedures.

Application fields

1. Pharmaceutical industry

Drug dispersion and emulsification: Ultrasonic homogenizer can disperse insoluble components (such as oily drugs) in drugs into nano-scale particles to increase the bioavailability of drugs.

Vaccines and biological products: Homogenize vaccines, antibodies and other biological products to improve their uniformity and stability.

2. Food industry:

Emulsification and dispersion: For example, in the production of salad dressings, creams, beverages and other foods, it is necessary to emulsify the oil and water phases or disperse solid particles in liquids.

Juice and beverages: Help pulp, fruit particles, etc. to be evenly distributed in beverages to prevent precipitation.

3. Cosmetics industry:

Lotions and creams: Ultrasonic homogenizers can help effectively emulsify oil and water components and improve the stability and texture of products.

Essence and perfume: Used to disperse essential oils, spices and other active ingredients to ensure the uniformity of products.

4. Chemical industry:

Homogenization of polymers: When used to synthesize polymer materials, it can evenly disperse monomers and improve the effect of polymerization reactions.

Pigment dispersion: In chemical products such as coatings and paints, ultrasonic homogenization can effectively disperse pigments and prevent precipitation.

5. Environmental protection:

Wastewater treatment: It can be used to disperse chemical agents in sewage, promote reactions, and improve sewage treatment efficiency.

6. Nanotechnology:

Nanomaterial preparation: It is widely used in the preparation and dispersion of nanomedicines, nanomaterials, nanoemulsions, etc.

| Item | RPS-S500 | RPS-S1000 | RPS-S1500 | RPS-S2000 | RPS-S3000 |

| Working frequency | 20kHz | 20kHz | 20kHz | 20kHz | 20kHz |

| Max power | 500W | 1000W | 1500W | 2000W | 3000W |

| Handing capacity | 0.5 to 2L/min | 0.5 to 3L/min | 0.5 to 4L/min | 1.0 to 6L/min | 1.0 to 8L/min |

| Apply | Production line, be used in combination | ||||

| Reaction tank | 10L,15L,20L,35L,stainless steel | ||||

| Working pressure | Max:5MPa | ||||

| Working temperature | Max: 350°C | ||||

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment