loading

| Availability: | |

|---|---|

| Quantity: | |

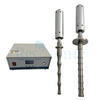

RPS-SONO20

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-S20-2000 |

| Minimum Order Quantity | 1set |

| Price | negotiation |

| Packaging Details | Foam And Wood Box |

| Delivery Time | 3days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 200 sets per month |

| Frequency | 20Khz | Power | 2000W |

|---|---|---|---|

| Weight | 14Kg | ||

| High Light | ultrasonic homogenizer sonicator,ultrasonic dispersion equipment | ||

Description:

RPS-Sonics manufactures the most technologically advanced and reliable ultrasonic processors in the industry for applications such as: dispersion of nanoparticles, nanotubes and Graphene; cell lysing and cell disruption; sample prep; ChIP assay; homogenization; extraction; atomization; and more.

Ultrasonic Preparation of Nanoscale Devices

• Particle size uniformity, strong dispersion, crystal type control, simple preparation, high yield

• Ultrasound nano-fabrication of monodisperse, well-defined nanoparticles and reduced energy consumption

• Ultrasonic nanoprocessing is easier to achieve mesoscopic mixing than conventional mixing techniques, eliminating local concentration variations, increasing reaction rates, stimulating the formation of new phases, inhibiting reunion

Ultrasonic power and cavitation are the top considerations when batch dispersing larger samples of nanoparticles in an ultrasonic cleaner. In this application the tank of the ultrasonic unit is filled with water treated with a surfactant to increase the efficiency of cavitation action. Nanoparticles such as single wall nanotubes (SWNT) are placed in vials containing a solution formulated to stabilize the dispersion. The vials are then fitted into holding devices and lowered into the ultrasonic cleaner solution. Only a portion of the vials must be immersed.

For example, multiple glass vials containing SWNT powders and a suitable solution can be immersed in an ultrasonic bath such as the powerful Elmasonic P30H available from Tovatech. This dual frequency unit operates at a user-selected 37 or 80 kHz and operates at 120 watts of power. For dispersing SWNT it is set to cavitate at the more vigorous 37 kHz, and allows operators to activate its pulse function that increases the power some 20%. This is sufficient power to disperse the SWNT as cavitation action passes from the bath solution through the vial walls and into the SWNT suspension. It is important to keep the bath cool, which can be accomplished by periodically refilling it with ice cold water and by using a cooling coil. At the end of the ultrasonic operation the samples are further processed according to established procedures.

| Item | RPS-S500 | RPS-S1000 | RPS-S1500 | RPS-S2000 | RPS-S3000 |

| Working frequency | 20kHz | 20kHz | 20kHz | 20kHz | 20kHz |

| Max power | 500W | 1000W | 1500W | 2000W | 3000W |

| Handing capacity | 0.5 to 2L/min | 0.5 to 3L/min | 0.5 to 4L/min | 1.0 to 6L/min | 1.0 to 8L/min |

| Apply | Production line, be used in combination | ||||

| Reaction tank | 10L,15L,20L,35L,stainless steel | ||||

| Working pressure | Max:5MPa | ||||

| Working temperature | Max: 350°C | ||||

Applications:

Ultrasonic have extremely capable and versatile, it can safely process a wide range of organic and inorganic materials – from microliters to liters. Typical applications include: sample preparation, dispersion, cell lysing, desegregation, homogenization, particle size reduction, soil testing, transesterification (including biodiesel production), nanotechnology (including nanoparticle and Graphene dispersion), acceleration of chemical reactions, degassing and atomization.

The new digital ultrasonicator is a powerful ultrasound processor for liquid treatments on bench-top and industrial scale. Common applications include homogenization, emulsification, dispersing & particle fine milling, lysis & extraction, dissolving vagy sonochemical reactions such as sono-synthesis and sono-catalysis. Touch display, browser remote control, automatic data recording. High Power and Full Process Control Powerful sonication is the process solution for manifold liquid processing applications, such as emulsifying, dispersing, milling vagy dissolving. The equipment provides intense ultrasound waves to fulfill demanding tasks without problems. To ensure a consistent process quality, not only the power delivered is essential, the control and monitoring of all important process parameters is key. The new generation of hdT ultrasonicators enables the operator to pilot the ultrasonic device via touch display or browser remote control.

• Dispersion

• Cell disruption

• Sample prep

• Homogenization

• Emulsification

• Nanoparticle dispersion

• Atomization

• Graphene dispersion

| Frequency | 20Khz | Power | 2000W |

|---|---|---|---|

| Weight | 14Kg | ||

| High Light | ultrasonic homogenizer sonicator,ultrasonic dispersion equipment | ||

Description:

RPS-Sonics manufactures the most technologically advanced and reliable ultrasonic processors in the industry for applications such as: dispersion of nanoparticles, nanotubes and Graphene; cell lysing and cell disruption; sample prep; ChIP assay; homogenization; extraction; atomization; and more.

Ultrasonic Preparation of Nanoscale Devices

• Particle size uniformity, strong dispersion, crystal type control, simple preparation, high yield

• Ultrasound nano-fabrication of monodisperse, well-defined nanoparticles and reduced energy consumption

• Ultrasonic nanoprocessing is easier to achieve mesoscopic mixing than conventional mixing techniques, eliminating local concentration variations, increasing reaction rates, stimulating the formation of new phases, inhibiting reunion

Ultrasonic power and cavitation are the top considerations when batch dispersing larger samples of nanoparticles in an ultrasonic cleaner. In this application the tank of the ultrasonic unit is filled with water treated with a surfactant to increase the efficiency of cavitation action. Nanoparticles such as single wall nanotubes (SWNT) are placed in vials containing a solution formulated to stabilize the dispersion. The vials are then fitted into holding devices and lowered into the ultrasonic cleaner solution. Only a portion of the vials must be immersed.

For example, multiple glass vials containing SWNT powders and a suitable solution can be immersed in an ultrasonic bath such as the powerful Elmasonic P30H available from Tovatech. This dual frequency unit operates at a user-selected 37 or 80 kHz and operates at 120 watts of power. For dispersing SWNT it is set to cavitate at the more vigorous 37 kHz, and allows operators to activate its pulse function that increases the power some 20%. This is sufficient power to disperse the SWNT as cavitation action passes from the bath solution through the vial walls and into the SWNT suspension. It is important to keep the bath cool, which can be accomplished by periodically refilling it with ice cold water and by using a cooling coil. At the end of the ultrasonic operation the samples are further processed according to established procedures.

| Item | RPS-S500 | RPS-S1000 | RPS-S1500 | RPS-S2000 | RPS-S3000 |

| Working frequency | 20kHz | 20kHz | 20kHz | 20kHz | 20kHz |

| Max power | 500W | 1000W | 1500W | 2000W | 3000W |

| Handing capacity | 0.5 to 2L/min | 0.5 to 3L/min | 0.5 to 4L/min | 1.0 to 6L/min | 1.0 to 8L/min |

| Apply | Production line, be used in combination | ||||

| Reaction tank | 10L,15L,20L,35L,stainless steel | ||||

| Working pressure | Max:5MPa | ||||

| Working temperature | Max: 350°C | ||||

Applications:

Ultrasonic have extremely capable and versatile, it can safely process a wide range of organic and inorganic materials – from microliters to liters. Typical applications include: sample preparation, dispersion, cell lysing, desegregation, homogenization, particle size reduction, soil testing, transesterification (including biodiesel production), nanotechnology (including nanoparticle and Graphene dispersion), acceleration of chemical reactions, degassing and atomization.

The new digital ultrasonicator is a powerful ultrasound processor for liquid treatments on bench-top and industrial scale. Common applications include homogenization, emulsification, dispersing & particle fine milling, lysis & extraction, dissolving vagy sonochemical reactions such as sono-synthesis and sono-catalysis. Touch display, browser remote control, automatic data recording. High Power and Full Process Control Powerful sonication is the process solution for manifold liquid processing applications, such as emulsifying, dispersing, milling vagy dissolving. The equipment provides intense ultrasound waves to fulfill demanding tasks without problems. To ensure a consistent process quality, not only the power delivered is essential, the control and monitoring of all important process parameters is key. The new generation of hdT ultrasonicators enables the operator to pilot the ultrasonic device via touch display or browser remote control.

• Dispersion

• Cell disruption

• Sample prep

• Homogenization

• Emulsification

• Nanoparticle dispersion

• Atomization

• Graphene dispersion

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment