loading

| Availability: | |

|---|---|

| Quantity: | |

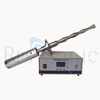

RPS-SONO20

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-S20-2000 |

| Minimum Order Quantity | 1set |

| Price | negotiation |

| Packaging Details | Foam And Wood Box |

| Delivery Time | 3days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 200 sets per month |

| Frequency | 20Khz | Power | 2000W |

|---|---|---|---|

| Weight | 14Kg | Name | Sonicator Ultrasonic Processor |

| Speed | <50L/HOUR | Generator | Digital |

| High Light | ultrasonic probe sonicator,ultrasonic homogenizer sonicator | ||

Description:

RPS-SONIC manufactures the most technologically advanced and reliable ultrasonic processors in the industry for applications such as: dispersion of nanoparticles, nanotubes and Graphene; cell lysing and cell disruption; sample prep; ChIP assay; homogenization; extraction; atomization; and more.

Ultrasonic Preparation of Nanoscale Devices

• Particle size uniformity, strong dispersion, crystal type control, simple preparation, high yield

• Ultrasound nano-fabrication of monodisperse, well-defined nanoparticles and reduced energy consumption

• Ultrasonic nanoprocessing is easier to achieve mesoscopic mixing than conventional mixing techniques, eliminating local concentration variations, increasing reaction rates, stimulating the formation of new phases, inhibiting reunion

Probe sonication is significantly more powerful and effective when compared to ultrasonic cleaner baths for nanoparticle applications. A cleaner bath requires hours to accomplish what a probe Sonicator can do in minutes. Sonicators can create a stable dispersion that can remain in suspension for many months as evidenced in this article excerpt:

Dispersions in vials (a) have coagulated CNTs in the body and at the bottom by means of bath sonication for 8 hours, (b) appear free-homogenous with probe sonication for 3 minutes, and (c) keep free-homogenous even after 4 months of sitting at room temperature. The concentration of Multi-Walled Carbon Nanotubes (MWCNTs) is 2500 mg/L and the MWCNTs/SDS ration is 1:10. (d) MWCNTs of (c) was diluted to 25 mg/L with deionized water.

| Item | Parameter |

| Frequency | 20Khz |

| Power | 2000W |

| Capacity | 10L |

| Horn diameter | 16mm |

| Probe dip depth | 80mm |

Applications:

Ultrasonic have extremely capable and versatile, it can safely process a wide range of organic and inorganic materials – from microliters to liters. Typical applications include: sample preparation, dispersion, cell lysing, desegregation, homogenization, particle size reduction, soil testing, transesterification (including biodiesel production), nanotechnology (including nanoparticle and Graphene dispersion), acceleration of chemical reactions, degassing and atomization.

The new digital ultrasonicator is a powerful ultrasound processor for liquid treatments on bench-top and industrial scale. Common applications include homogenization, emulsification, dispersing & particle fine milling, lysis & extraction, dissolving vagy sonochemical reactions such as sono-synthesis and sono-catalysis. Touch display, browser remote control, automatic data recording. High Power and Full Process Control Powerful sonication is the process solution for manifold liquid processing applications, such as emulsifying, dispersing, milling vagy dissolving. The equipment provides intense ultrasound waves to fulfill demanding tasks without problems. To ensure a consistent process quality, not only the power delivered is essential, the control and monitoring of all important process parameters is key. The new generation of hdT ultrasonicators enables the operator to pilot the ultrasonic device via touch display or browser remote control.

• Dispersion

• Cell disruption

• Sample prep

• Homogenization

• Emulsification

• Nanoparticle dispersion

• Atomization

• Graphene dispersion

| Frequency | 20Khz | Power | 2000W |

|---|---|---|---|

| Weight | 14Kg | Name | Sonicator Ultrasonic Processor |

| Speed | <50L/HOUR | Generator | Digital |

| High Light | ultrasonic probe sonicator,ultrasonic homogenizer sonicator | ||

Description:

RPS-SONIC manufactures the most technologically advanced and reliable ultrasonic processors in the industry for applications such as: dispersion of nanoparticles, nanotubes and Graphene; cell lysing and cell disruption; sample prep; ChIP assay; homogenization; extraction; atomization; and more.

Ultrasonic Preparation of Nanoscale Devices

• Particle size uniformity, strong dispersion, crystal type control, simple preparation, high yield

• Ultrasound nano-fabrication of monodisperse, well-defined nanoparticles and reduced energy consumption

• Ultrasonic nanoprocessing is easier to achieve mesoscopic mixing than conventional mixing techniques, eliminating local concentration variations, increasing reaction rates, stimulating the formation of new phases, inhibiting reunion

Probe sonication is significantly more powerful and effective when compared to ultrasonic cleaner baths for nanoparticle applications. A cleaner bath requires hours to accomplish what a probe Sonicator can do in minutes. Sonicators can create a stable dispersion that can remain in suspension for many months as evidenced in this article excerpt:

Dispersions in vials (a) have coagulated CNTs in the body and at the bottom by means of bath sonication for 8 hours, (b) appear free-homogenous with probe sonication for 3 minutes, and (c) keep free-homogenous even after 4 months of sitting at room temperature. The concentration of Multi-Walled Carbon Nanotubes (MWCNTs) is 2500 mg/L and the MWCNTs/SDS ration is 1:10. (d) MWCNTs of (c) was diluted to 25 mg/L with deionized water.

| Item | Parameter |

| Frequency | 20Khz |

| Power | 2000W |

| Capacity | 10L |

| Horn diameter | 16mm |

| Probe dip depth | 80mm |

Applications:

Ultrasonic have extremely capable and versatile, it can safely process a wide range of organic and inorganic materials – from microliters to liters. Typical applications include: sample preparation, dispersion, cell lysing, desegregation, homogenization, particle size reduction, soil testing, transesterification (including biodiesel production), nanotechnology (including nanoparticle and Graphene dispersion), acceleration of chemical reactions, degassing and atomization.

The new digital ultrasonicator is a powerful ultrasound processor for liquid treatments on bench-top and industrial scale. Common applications include homogenization, emulsification, dispersing & particle fine milling, lysis & extraction, dissolving vagy sonochemical reactions such as sono-synthesis and sono-catalysis. Touch display, browser remote control, automatic data recording. High Power and Full Process Control Powerful sonication is the process solution for manifold liquid processing applications, such as emulsifying, dispersing, milling vagy dissolving. The equipment provides intense ultrasound waves to fulfill demanding tasks without problems. To ensure a consistent process quality, not only the power delivered is essential, the control and monitoring of all important process parameters is key. The new generation of hdT ultrasonicators enables the operator to pilot the ultrasonic device via touch display or browser remote control.

• Dispersion

• Cell disruption

• Sample prep

• Homogenization

• Emulsification

• Nanoparticle dispersion

• Atomization

• Graphene dispersion

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment