loading

| Availability: | |

|---|---|

| Quantity: | |

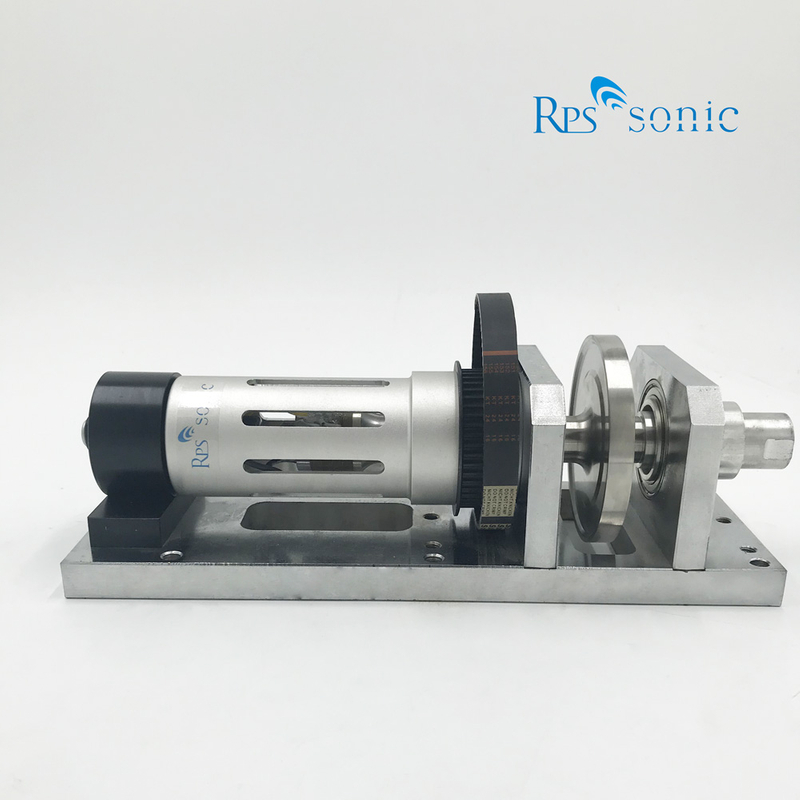

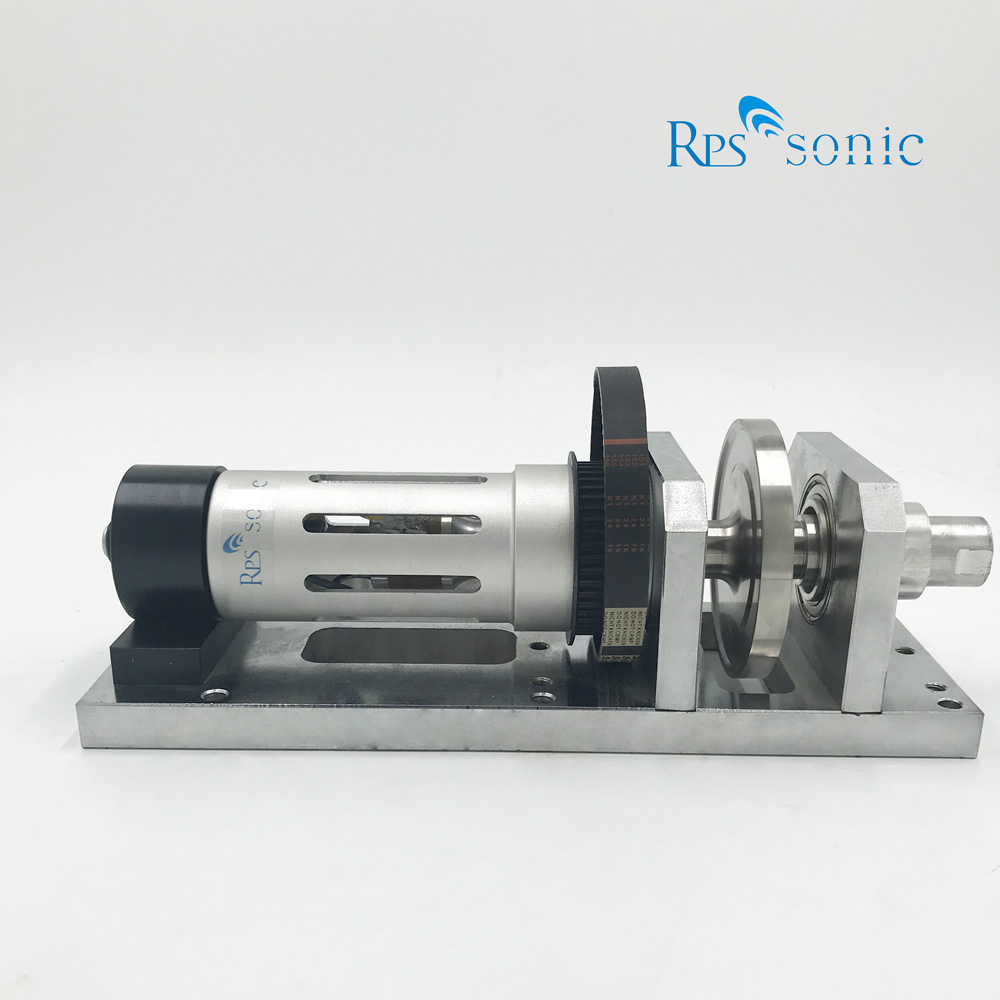

RPS-R35

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-S800 |

| Minimum Order Quantity | 1set |

| Price | negotiation |

| Packaging Details | FOAM AND CARTON |

| Delivery Time | 5days |

| Payment Terms | T/T, Western Union, MoneyGram, paypal |

| Supply Ability | 500 sets per month |

| Name | Ultrasonic Sewing Machine | Frequency | 35khz |

|---|---|---|---|

| Power | 800W | Horn Material | Rapid Steel,Titanium |

| Generator | Digital | Weight | 8.5Kg |

| High Light | ultrasonic sealing machine,ultrasonic seam welding equipment | ||

The closure process for packaging is a key process. It ensures the protective function of packaging and assures the packaged goods a long life. In this context, efficient and reliable sealing processes are essential for the production of sustainable packages.

Although the ultrasonic sealing method has marginal advantages for bulk materials such as wheat flour, conduction sealing was shown to be better for other products. A comparison of the energy consumption during the ultrasonic and conduction sealing verified the advantages of ultrasonic sealing. In particular for thick packaging films, the amount of energy required for bonding is significantly lower than for conduction sealing.

Ultrasonic bonding is the process of using high-frequency compression/relaxation of materials against specially designed anvil patterns that cause them to heat at the molecular level and melt. This process enables the materials to flow around the shapes of the anvil and adhere to each other and to other materials that are in the web matrix. It is only a part of the ultrasonic sewing machine.

It need be assembled on the ulltrasonic sewing machine, and drive by an other rotary horn.

RPS-SONIC specializes in manufacturing ultrasonic seam welding solutions for rotational systems.

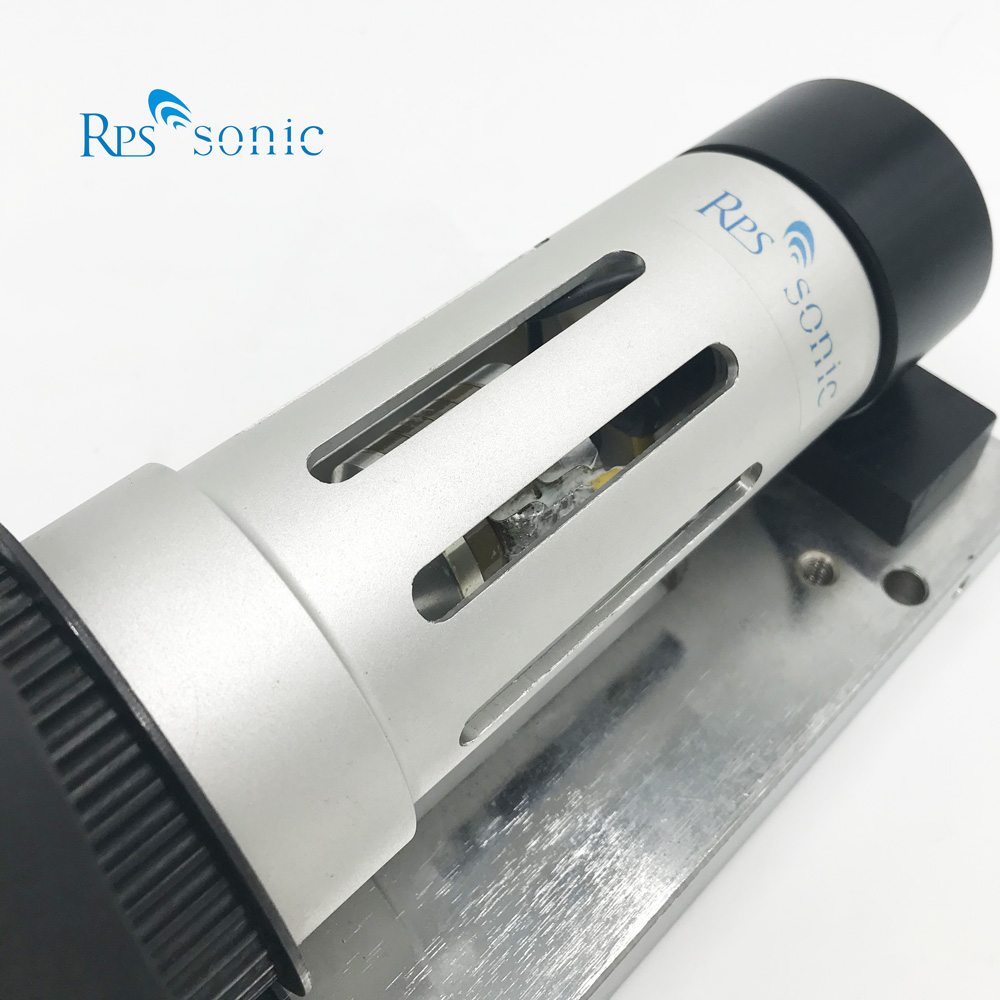

The Ultrasonic seamless sewing module is composed of ultrasonic transducer (converter) with cover,booster, horn (sonotrode) generator and rack.

The ultrasonic rotary type vibration is used for cloth’s sewing and cutting, which is the newest one of technical achievements in the world. Our company closely follows up this newest foreign scientific research achievement, thus developed the ultrasonic seamless sewing core Part in China. It’s the key part for ultrasonic seamless sewing machine (Also named ultrasonic radial direction sewing machine). It’s our company’s original creation, which thoroughly solved the common problems caused by ultrasonic vertical vibration:the ultrasonic horn’s moving direction and the cloth’s one are inconsistency and asynchrony. With the help of our ultrasonic seamless sewing core Part, the cloth’s sewing accuracy is greatly improved. Thus it make it possible that widely use the ultrasonic technology in garment sewing industry. The ultrasonic seamless sewing has much advantages: Fast welding speed, high strength, nice welding seam, good sealing,low energy consumption and easy operations so on. So it’s development trend for sewing technology.

| Item | Parameter |

| Frequency | 35KHZ |

| Power | 800W |

| Rotary horn diameter | 106MM |

| Amplitude | 28μm |

| Rotary horn material | Rapid steel,Titanium |

| Speed | 0.1-5m/s |

| Electrical tension: | 220 V single phase, 50 or 60 Hz |

| Welding width | 8mm |

Characteristics:

1. Seamming,trimming and embossing without glue, thread or other consumables

2. More faster and cost effective than traditional sewing machine and adhesive ways

3. Eliminates fraying or unraveling of bonded edges and seams

4. Multifunctional and thousands of designs available

5. Requires minimum training and maintenance

6. Super strong ultrasonic power meets the needs of different fabric thickness

Fast and cost-effective weaving;

Resilient seams;

No need for consumables such as tape, clips or glue;

Constant results;

No cooling times and reduced maintenance costs;

No shooting time for the stapler tool;

Edging in one operation

No need for needles, thread, spools and any activities related to color matching, inventories, winding and trimming;

Environmentally-friendly because it does not need any adhesives and solvents;

Edges get sealed without leaving any stitch holes, thus preventing penetration from chemical agents, bloodborne pathogens and other particles.

Instead of needles, thread, glues or other adhesives, ultrasonic sewing equipment uses a patented rotary system, coupled with high-frequency vibrations, to bond synthetic or blended materials containing up to 40 percent natural fibers.

Resembling a traditional sewing machine, the ultrasonic sewing machine channels the ultrasonic vibrations between a horn and rotating wheel, producing a localized heat buildup which causes the synthetic fibers to soften and fuse. This creates a strong molecular bond that’s impervious to moisture. Explains Alleman, “the resulting barrier seams are sealed, secure, ultra-reliable and soft-to-the-touch without the safety issues caused by stitch holes, glue gaps, fraying or unraveling.”

| Name | Ultrasonic Sewing Machine | Frequency | 35khz |

|---|---|---|---|

| Power | 800W | Horn Material | Rapid Steel,Titanium |

| Generator | Digital | Weight | 8.5Kg |

| High Light | ultrasonic sealing machine,ultrasonic seam welding equipment | ||

The closure process for packaging is a key process. It ensures the protective function of packaging and assures the packaged goods a long life. In this context, efficient and reliable sealing processes are essential for the production of sustainable packages.

Although the ultrasonic sealing method has marginal advantages for bulk materials such as wheat flour, conduction sealing was shown to be better for other products. A comparison of the energy consumption during the ultrasonic and conduction sealing verified the advantages of ultrasonic sealing. In particular for thick packaging films, the amount of energy required for bonding is significantly lower than for conduction sealing.

Ultrasonic bonding is the process of using high-frequency compression/relaxation of materials against specially designed anvil patterns that cause them to heat at the molecular level and melt. This process enables the materials to flow around the shapes of the anvil and adhere to each other and to other materials that are in the web matrix. It is only a part of the ultrasonic sewing machine.

It need be assembled on the ulltrasonic sewing machine, and drive by an other rotary horn.

RPS-SONIC specializes in manufacturing ultrasonic seam welding solutions for rotational systems.

The Ultrasonic seamless sewing module is composed of ultrasonic transducer (converter) with cover,booster, horn (sonotrode) generator and rack.

The ultrasonic rotary type vibration is used for cloth’s sewing and cutting, which is the newest one of technical achievements in the world. Our company closely follows up this newest foreign scientific research achievement, thus developed the ultrasonic seamless sewing core Part in China. It’s the key part for ultrasonic seamless sewing machine (Also named ultrasonic radial direction sewing machine). It’s our company’s original creation, which thoroughly solved the common problems caused by ultrasonic vertical vibration:the ultrasonic horn’s moving direction and the cloth’s one are inconsistency and asynchrony. With the help of our ultrasonic seamless sewing core Part, the cloth’s sewing accuracy is greatly improved. Thus it make it possible that widely use the ultrasonic technology in garment sewing industry. The ultrasonic seamless sewing has much advantages: Fast welding speed, high strength, nice welding seam, good sealing,low energy consumption and easy operations so on. So it’s development trend for sewing technology.

| Item | Parameter |

| Frequency | 35KHZ |

| Power | 800W |

| Rotary horn diameter | 106MM |

| Amplitude | 28μm |

| Rotary horn material | Rapid steel,Titanium |

| Speed | 0.1-5m/s |

| Electrical tension: | 220 V single phase, 50 or 60 Hz |

| Welding width | 8mm |

Characteristics:

1. Seamming,trimming and embossing without glue, thread or other consumables

2. More faster and cost effective than traditional sewing machine and adhesive ways

3. Eliminates fraying or unraveling of bonded edges and seams

4. Multifunctional and thousands of designs available

5. Requires minimum training and maintenance

6. Super strong ultrasonic power meets the needs of different fabric thickness

Fast and cost-effective weaving;

Resilient seams;

No need for consumables such as tape, clips or glue;

Constant results;

No cooling times and reduced maintenance costs;

No shooting time for the stapler tool;

Edging in one operation

No need for needles, thread, spools and any activities related to color matching, inventories, winding and trimming;

Environmentally-friendly because it does not need any adhesives and solvents;

Edges get sealed without leaving any stitch holes, thus preventing penetration from chemical agents, bloodborne pathogens and other particles.

Instead of needles, thread, glues or other adhesives, ultrasonic sewing equipment uses a patented rotary system, coupled with high-frequency vibrations, to bond synthetic or blended materials containing up to 40 percent natural fibers.

Resembling a traditional sewing machine, the ultrasonic sewing machine channels the ultrasonic vibrations between a horn and rotating wheel, producing a localized heat buildup which causes the synthetic fibers to soften and fuse. This creates a strong molecular bond that’s impervious to moisture. Explains Alleman, “the resulting barrier seams are sealed, secure, ultra-reliable and soft-to-the-touch without the safety issues caused by stitch holes, glue gaps, fraying or unraveling.”

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment