loading

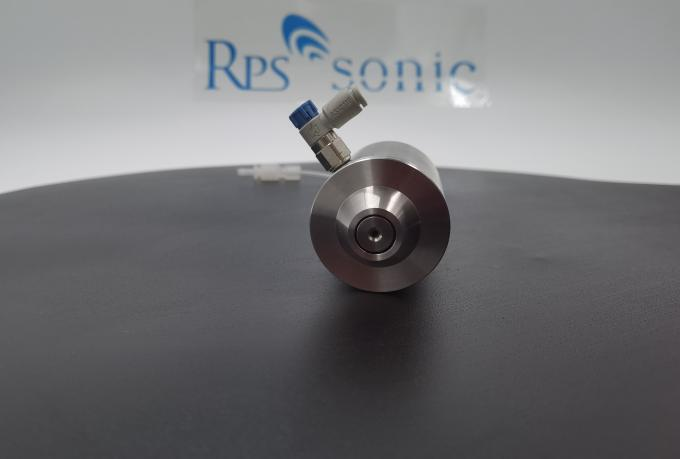

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-AT40 |

| Minimum Order Quantity | 1set |

| Packaging Details | carton |

| Payment Terms | T/T |

| Supply Ability | 200pcs |

| Material | Titanium | Frequency | 40Khz |

|---|---|---|---|

| Power Supply | 10-100W | Raw Coating Material Saving | Over 90% |

| High Light | Titanium Ultrasonic Spray Nozzle Systems,Ultrasonic Atomizing Nozzle Anti Corrosion,100W Ultrasonic Spray Nozzle Systems | ||

Ultrasonic atomizing flux process introduction Ultrasonic atomizing . The nozzle uses ultrasonic energy to convert the liquid into a fine mist of low-viscosity water droplets. This technology is used in the electronics assembly industry, especially in the application of liquid solder flux for printed circuit assembly, multichip modules (MCM, multichip module), discrete components, ball grid arrays (BGA) and chip scale packaging (CSP), Find a wide range of applications. Low-viscosity spray is a key factor in these applications, because with air or nitrogen, the spray shape can be as small as 0.070" and as large as 18" width depending on the nozzle. Due to this capability, a tiny amount of flux can be applied to components such as BGA, and large printed circuit assemblies can be covered with flux before wave soldering. Because the velocity generated by the ultrasonic nozzle is generally a few inches per second, it is simple to deliver the spray and shape it in a clear, slow-moving air stream. When the spray is directed at the target surface to be coated, the liquid shows a tendency to bounce off the surface and enter the environment.

Description:

Another characteristic of the ultrasonic nozzle is that it can accommodate a wide range of flow rates. Ultrasonic atomization does not require pressure. The speed of liquid atomization is only determined by the speed at which it is introduced into the nozzle. The nozzle can be designed to handle very small conveying speeds, as low as a few milliliters per minute, or relatively large flow rates, up to a few hundred milliliters per minute. Flux spraying Since the early 1990s, ultrasonic nozzles have been successfully used for flux spraying for on-line PCB wave soldering operations, mainly for products such as no-clean, water-soluble, VOC-free and RA (fully activated rosin) Soldering flux. In order to cover the entire board surface with flux, the spray from a static nozzle is conveyed in low-speed air to form a wide, narrow fog band, which is evenly deposited on the bottom surface of the board as the board passes through the spray. The same technique can be used to spray from the top down. Flux spray has advantages over old flux application methods, such as foaming or wave flux. Compared with the old method, flux spray reduces flux consumption by 70%, eliminates the need for flux thinner, provides better process control, and reduces defects. In the past few years, the industry trend has shifted to flux spray

Features

Uniform coating: uniformity >95%

Saving raw materials: raw material utilization rate is over 85%, 4 times that of traditional air spray nozzle

High control accuracy of coating thickness : 20 nm to tens of micron coatings can be precisely sprayed.

Non clogging

Anti-corrosion nozzle

High precision, high controllable spray.

Tech. info:

| Atomized particles | 15-40um |

| Spraying width | 10~50mm |

| Spray flow | >200ML/min |

| Spray height | 30-80mm |

| Suitable for liquid viscosity | <30cps |

| Suspension particle size | <15um |

| Diversion air pressure | <0.05mpa |

Applications

Electronics: Photoresists onto Wafer ,Sensors, PCB Fluxing, Semiconductors etc.

Industrial: Glass, Touch Screen, etc.

Medical: Medical Textile,Stents, Balloon Catheters, Diagnostic Device etc.

Energy: Fuel Cell, Solar Cell, etc.

| Material | Titanium | Frequency | 40Khz |

|---|---|---|---|

| Power Supply | 10-100W | Raw Coating Material Saving | Over 90% |

| High Light | Titanium Ultrasonic Spray Nozzle Systems,Ultrasonic Atomizing Nozzle Anti Corrosion,100W Ultrasonic Spray Nozzle Systems | ||

Ultrasonic atomizing flux process introduction Ultrasonic atomizing . The nozzle uses ultrasonic energy to convert the liquid into a fine mist of low-viscosity water droplets. This technology is used in the electronics assembly industry, especially in the application of liquid solder flux for printed circuit assembly, multichip modules (MCM, multichip module), discrete components, ball grid arrays (BGA) and chip scale packaging (CSP), Find a wide range of applications. Low-viscosity spray is a key factor in these applications, because with air or nitrogen, the spray shape can be as small as 0.070" and as large as 18" width depending on the nozzle. Due to this capability, a tiny amount of flux can be applied to components such as BGA, and large printed circuit assemblies can be covered with flux before wave soldering. Because the velocity generated by the ultrasonic nozzle is generally a few inches per second, it is simple to deliver the spray and shape it in a clear, slow-moving air stream. When the spray is directed at the target surface to be coated, the liquid shows a tendency to bounce off the surface and enter the environment.

Description:

Another characteristic of the ultrasonic nozzle is that it can accommodate a wide range of flow rates. Ultrasonic atomization does not require pressure. The speed of liquid atomization is only determined by the speed at which it is introduced into the nozzle. The nozzle can be designed to handle very small conveying speeds, as low as a few milliliters per minute, or relatively large flow rates, up to a few hundred milliliters per minute. Flux spraying Since the early 1990s, ultrasonic nozzles have been successfully used for flux spraying for on-line PCB wave soldering operations, mainly for products such as no-clean, water-soluble, VOC-free and RA (fully activated rosin) Soldering flux. In order to cover the entire board surface with flux, the spray from a static nozzle is conveyed in low-speed air to form a wide, narrow fog band, which is evenly deposited on the bottom surface of the board as the board passes through the spray. The same technique can be used to spray from the top down. Flux spray has advantages over old flux application methods, such as foaming or wave flux. Compared with the old method, flux spray reduces flux consumption by 70%, eliminates the need for flux thinner, provides better process control, and reduces defects. In the past few years, the industry trend has shifted to flux spray

Features

Uniform coating: uniformity >95%

Saving raw materials: raw material utilization rate is over 85%, 4 times that of traditional air spray nozzle

High control accuracy of coating thickness : 20 nm to tens of micron coatings can be precisely sprayed.

Non clogging

Anti-corrosion nozzle

High precision, high controllable spray.

Tech. info:

| Atomized particles | 15-40um |

| Spraying width | 10~50mm |

| Spray flow | >200ML/min |

| Spray height | 30-80mm |

| Suitable for liquid viscosity | <30cps |

| Suspension particle size | <15um |

| Diversion air pressure | <0.05mpa |

Applications

Electronics: Photoresists onto Wafer ,Sensors, PCB Fluxing, Semiconductors etc.

Industrial: Glass, Touch Screen, etc.

Medical: Medical Textile,Stents, Balloon Catheters, Diagnostic Device etc.

Energy: Fuel Cell, Solar Cell, etc.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!