loading

| Availability: | |

|---|---|

| Quantity: | |

RPS-AT50

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-D50 |

| Minimum Order Quantity | 1set |

| Packaging Details | carton |

| Payment Terms | T/T |

| Supply Ability | 200pcs |

| Material | Titanium | Frequency | 50Khz |

|---|---|---|---|

| Power Supply | 10-100W | Raw Coating Material Saving | Over 90% |

| High Light | Photoresists Ultrasonic Spray Nozzles,Wafer Coatings Ultrasonic Spray Nozzles,20ML/min Ultrasonic Spray Nozzles | ||

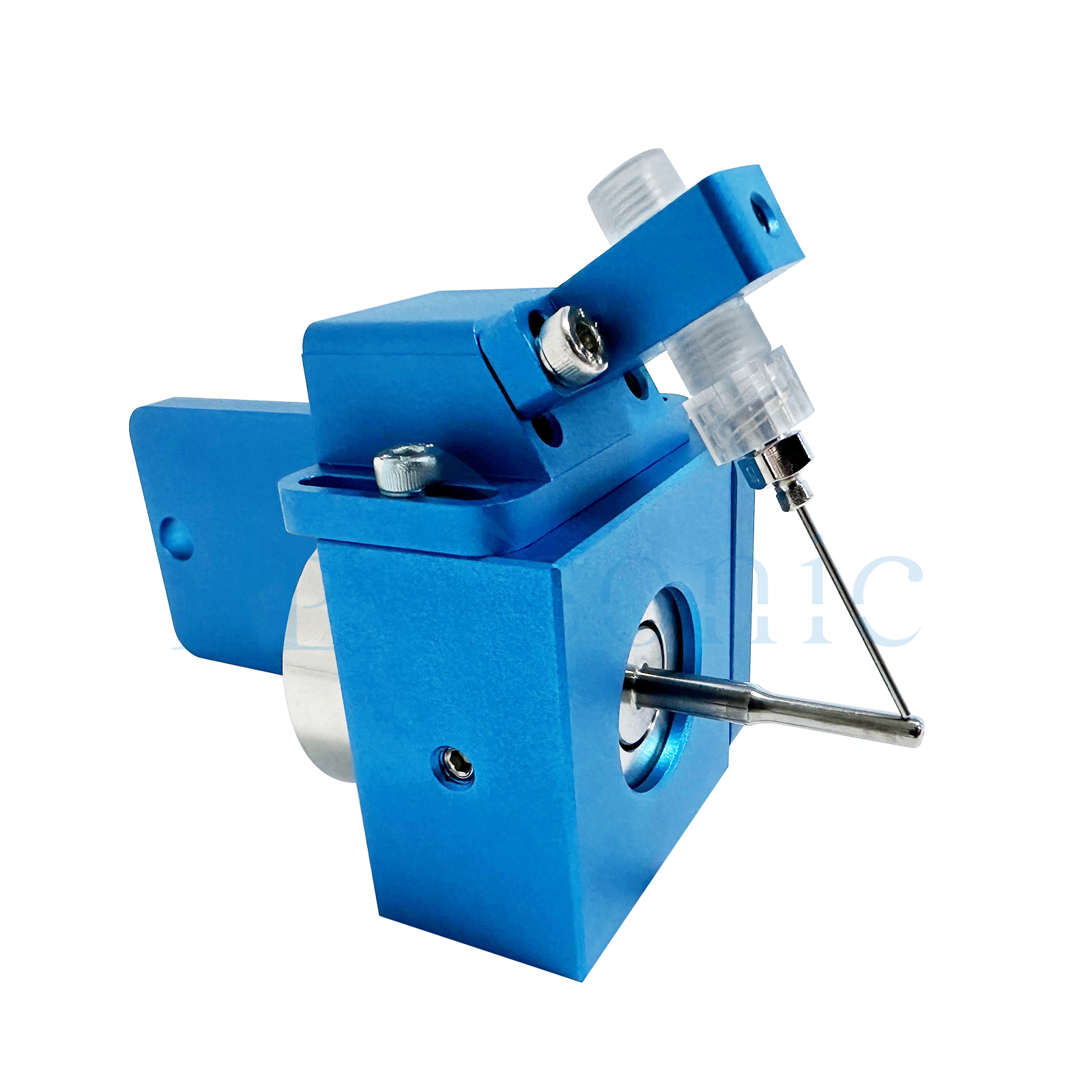

50Khz Titanium Cone Mist Ultrasonic Spray Nozzle For Photoresists Onto Wafer Coatings,Small With Of Spray Area

50Khz Cone mist ultrasonic spray Nozzle for Photoresists onto Wafer coatings ,small spray width

Ultrasonic atomization spraying is the use of piezoelectric effect to convert electrical energy into high-frequency mechanical energy, to break up the molecular bonds between liquid water molecules to produce a natural and elegant water mist, so as to atomize the liquid without heating or adding any chemical reagents. . Ultrasonic high-frequency oscillation is used to atomize the liquid into uniform micron-sized particles. Compared with traditional pressure nozzles, ultrasonic spraying can obtain a more uniform, thinner and more controllable film coating, and it is not easy to block the nozzles. Because the ultrasonic nozzle only needs a tiny air volume of kilopascals, and there is almost no splash during the spraying process, the paint utilization rate is as high as 90%. In the ultrasonic spraying process, the droplet size and distribution can be precisely controlled, so that very small droplet particles can be quickly evaporated, thereby producing particles with a high specific surface area. Ultrasonic atomization spraying is different from traditional atomization spraying. Traditional spraying relies on pressure and high-speed motion to shear the fluid into small droplets. Ultrasonic spraying uses only ultrasonic vibration energy for atomization. Ultrasonic atomization spray equipment is regarded as a "green" technology due to its low energy consumption and high efficiency, and is an ideal choice for key fluid applications. With its unique gentle spray characteristics, the device greatly reduces back spray, thereby reducing costs and pollution to the surrounding air. At the same time, this new technology also expands more application areas, such as spraying at low flow rates.

Description:

Cone mist of ultrasonic spray nozzle is an ultrasonic atomizing nozzle with a cyclonic cone spray. The ultrasonic atomizing nozzle technology adopts a special vortex flow channel design to transform the carrier gas into a uniform rotating airflow, so that the liquid mist after ultrasonic atomization is scattered and spurted in the form of a cyclone, as enlarges the spraying area of the ultrasonic spray nozzle. It is also possible to spray on angled substrates such as vertical or curved surfaces.

A typical application of a Cone mist ultrasonic spray nozzle is photoresist coating of a semiconductor wafer, which is to spray coating the photoresist onto a semiconductor wafer. Since the mist sprayed by Cone mist ultrasonic spray nozzle is rotationally scattered, not only the photoresist film can be uniformly formed on the plane of the wafer, but also a uniform package can be formed on the sidewalls and the corners of the wafer microstructure photoresist film. In addition, Cone mist ultrasonic nozzle can also be applied to, for example, thin film solar cell spray coating, perovskite solar cell spray coating, AR anti-reflective layer spray coating, thermal film spray coating, super hydrophobic spray coating, PCB flux spray coating, etc.

Features

Uniform coating: uniformity >95%

Saving raw materials: raw material utilization rate is over 85%, 4 times that of traditional air spray nozzle

High control accuracy of coating thickness : 20 nm to tens of micron coatings can be precisely sprayed.

Non clogging

Anti-corrosion nozzle

High precision, high controllable spray.

Tech. info:

| Atomized particles | 15-40um |

| Spraying width | 40-80mm |

| Spray flow | 0.5-20ML/min |

| Spray height | 30-80mm |

| Suitable for liquid viscosity | <30cps |

| Suspension particle size | <15um |

| Diversion air pressure | <0.05mpa |

Applications

Electronics: Photoresists onto Wafer ,Sensors, PCB Fluxing, Semiconductors etc.

Industrial: Glass, Touch Screen, etc.

Medical: Medical Textile,Stents, Balloon Catheters, Diagnostic Device etc.

Energy: Fuel Cell, Solar Cell, etc.

| Material | Titanium | Frequency | 50Khz |

|---|---|---|---|

| Power Supply | 10-100W | Raw Coating Material Saving | Over 90% |

| High Light | Photoresists Ultrasonic Spray Nozzles,Wafer Coatings Ultrasonic Spray Nozzles,20ML/min Ultrasonic Spray Nozzles | ||

50Khz Titanium Cone Mist Ultrasonic Spray Nozzle For Photoresists Onto Wafer Coatings,Small With Of Spray Area

50Khz Cone mist ultrasonic spray Nozzle for Photoresists onto Wafer coatings ,small spray width

Ultrasonic atomization spraying is the use of piezoelectric effect to convert electrical energy into high-frequency mechanical energy, to break up the molecular bonds between liquid water molecules to produce a natural and elegant water mist, so as to atomize the liquid without heating or adding any chemical reagents. . Ultrasonic high-frequency oscillation is used to atomize the liquid into uniform micron-sized particles. Compared with traditional pressure nozzles, ultrasonic spraying can obtain a more uniform, thinner and more controllable film coating, and it is not easy to block the nozzles. Because the ultrasonic nozzle only needs a tiny air volume of kilopascals, and there is almost no splash during the spraying process, the paint utilization rate is as high as 90%. In the ultrasonic spraying process, the droplet size and distribution can be precisely controlled, so that very small droplet particles can be quickly evaporated, thereby producing particles with a high specific surface area. Ultrasonic atomization spraying is different from traditional atomization spraying. Traditional spraying relies on pressure and high-speed motion to shear the fluid into small droplets. Ultrasonic spraying uses only ultrasonic vibration energy for atomization. Ultrasonic atomization spray equipment is regarded as a "green" technology due to its low energy consumption and high efficiency, and is an ideal choice for key fluid applications. With its unique gentle spray characteristics, the device greatly reduces back spray, thereby reducing costs and pollution to the surrounding air. At the same time, this new technology also expands more application areas, such as spraying at low flow rates.

Description:

Cone mist of ultrasonic spray nozzle is an ultrasonic atomizing nozzle with a cyclonic cone spray. The ultrasonic atomizing nozzle technology adopts a special vortex flow channel design to transform the carrier gas into a uniform rotating airflow, so that the liquid mist after ultrasonic atomization is scattered and spurted in the form of a cyclone, as enlarges the spraying area of the ultrasonic spray nozzle. It is also possible to spray on angled substrates such as vertical or curved surfaces.

A typical application of a Cone mist ultrasonic spray nozzle is photoresist coating of a semiconductor wafer, which is to spray coating the photoresist onto a semiconductor wafer. Since the mist sprayed by Cone mist ultrasonic spray nozzle is rotationally scattered, not only the photoresist film can be uniformly formed on the plane of the wafer, but also a uniform package can be formed on the sidewalls and the corners of the wafer microstructure photoresist film. In addition, Cone mist ultrasonic nozzle can also be applied to, for example, thin film solar cell spray coating, perovskite solar cell spray coating, AR anti-reflective layer spray coating, thermal film spray coating, super hydrophobic spray coating, PCB flux spray coating, etc.

Features

Uniform coating: uniformity >95%

Saving raw materials: raw material utilization rate is over 85%, 4 times that of traditional air spray nozzle

High control accuracy of coating thickness : 20 nm to tens of micron coatings can be precisely sprayed.

Non clogging

Anti-corrosion nozzle

High precision, high controllable spray.

Tech. info:

| Atomized particles | 15-40um |

| Spraying width | 40-80mm |

| Spray flow | 0.5-20ML/min |

| Spray height | 30-80mm |

| Suitable for liquid viscosity | <30cps |

| Suspension particle size | <15um |

| Diversion air pressure | <0.05mpa |

Applications

Electronics: Photoresists onto Wafer ,Sensors, PCB Fluxing, Semiconductors etc.

Industrial: Glass, Touch Screen, etc.

Medical: Medical Textile,Stents, Balloon Catheters, Diagnostic Device etc.

Energy: Fuel Cell, Solar Cell, etc.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment