loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-C40 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 40Khz | Power | 300w |

|---|---|---|---|

| Horn Material | Titanium | Outer Shell | Alumium |

| Generator | Digital | Type | Handheld |

| Voltage | 220/110V | Weight | 6kg |

| High Light | Titanium Horn Ultrasonic Cutting Device,Handheld Ultrasonic Cutting Device,300w Ultrasonic Cutting Device | ||

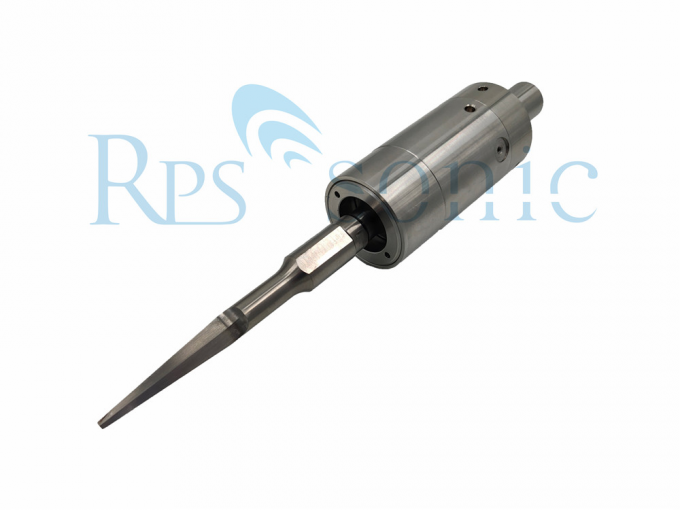

40Khz 300w Handheld Ultrasonic Cutting Device Auto Tracking With Titanium Ultrasonic Cutting Blade

40Khz 300w Handheld Ultrasonic cutting device for foam cutting

Parameter

| Frequency | 40Khz |

| Frequency adjustment | Auto-tracking type |

| Max. power output | 300W |

| Power output | Infinitive adjustment |

| Power supply | AC200V 50/60Hz |

| Outer dimension (mm) | 120*120*380 |

| Weight | 6kg |

| Blade thickness | 0.6mm |

Description

The principle of the 40K ultrasonic hand-held cutter is completely different from the traditional cutting. It uses ultrasonic energy to heat and melt the material to be cut locally, thereby

To achieve the purpose of cutting materials. Therefore, ultrasonic cutting does not require a sharp edge, nor does it require a lot of pressure, and will not cause chipping or damage to the material being cut. Simultaneously,

Because the cutting knife is doing ultrasonic vibration, the friction resistance is very small, and the material to be cut is not easy to stick to the blade. This pair of viscous and elastic materials, frozen materials, such as food, rubber

Etc., or cutting objects that are inconvenient to apply pressure, especially effective.

The 40K ultrasonic hand-held cutting knife is a kind of equipment that uses wave energy for cutting processing. Its major feature is that it does not require cutting edges. In other words, instead of using a blade in the traditional sense

mouth. Traditional cutting uses a knife with a sharp edge to press against the material to be cut. This pressure is concentrated at the cutting edge, and the pressure is very large, exceeding the shear of the material being cut.

Shear strength, the molecular bond of the material is pulled apart, it is cut. Since the material is pulled apart by strong pressure, the cutting edge of the cutting tool should be very sharp.

The material itself has to bear relatively large pressure. The cutting effect is not good for soft and elastic materials, and it is more difficult for sticky materials.

The basic structure of the ultrasonic anvil-type cutting machine is similar to that of the ultrasonic cutter-type cutting machine, except that the ultrasonic output part is not a cutting knife, but a standard ultrasonic plane mold.

With. Here, the mold is equivalent to an anvil. It's just that this is a cutting board that is vibrating ultrasonically. The cutting knife still uses the traditional, any shape.

However, it's just that the sharpness of the cutting edge has been reduced, and the life of the cutter has been greatly extended.

Application

In many cases, due to the effect of ultrasound, traditional cutting blades also allow great changes. Typically, the cutter is transformed into a cylindrical shape with raised patterns

Wheels, commonly known as flower wheels. The protruding part is equivalent to the cutting edge of the cutter, and the material to be cut passes between the flower wheel and the ultrasonic cutting board. This combination can cut flowers with changes*

Patterns are very low cost and efficient. This cutting method is suitable for cutting thin-film materials, such as all kinds of trademarks, clothing lace, cloth cutting, decorative bead cutting, natural fiber

Vinyl, synthetic fiber, non-woven fabric, synthetic resin, paper, film cutting, slitting, etc.

| Frequency | 40Khz | Power | 300w |

|---|---|---|---|

| Horn Material | Titanium | Outer Shell | Alumium |

| Generator | Digital | Type | Handheld |

| Voltage | 220/110V | Weight | 6kg |

| High Light | Titanium Horn Ultrasonic Cutting Device,Handheld Ultrasonic Cutting Device,300w Ultrasonic Cutting Device | ||

40Khz 300w Handheld Ultrasonic Cutting Device Auto Tracking With Titanium Ultrasonic Cutting Blade

40Khz 300w Handheld Ultrasonic cutting device for foam cutting

Parameter

| Frequency | 40Khz |

| Frequency adjustment | Auto-tracking type |

| Max. power output | 300W |

| Power output | Infinitive adjustment |

| Power supply | AC200V 50/60Hz |

| Outer dimension (mm) | 120*120*380 |

| Weight | 6kg |

| Blade thickness | 0.6mm |

Description

The principle of the 40K ultrasonic hand-held cutter is completely different from the traditional cutting. It uses ultrasonic energy to heat and melt the material to be cut locally, thereby

To achieve the purpose of cutting materials. Therefore, ultrasonic cutting does not require a sharp edge, nor does it require a lot of pressure, and will not cause chipping or damage to the material being cut. Simultaneously,

Because the cutting knife is doing ultrasonic vibration, the friction resistance is very small, and the material to be cut is not easy to stick to the blade. This pair of viscous and elastic materials, frozen materials, such as food, rubber

Etc., or cutting objects that are inconvenient to apply pressure, especially effective.

The 40K ultrasonic hand-held cutting knife is a kind of equipment that uses wave energy for cutting processing. Its major feature is that it does not require cutting edges. In other words, instead of using a blade in the traditional sense

mouth. Traditional cutting uses a knife with a sharp edge to press against the material to be cut. This pressure is concentrated at the cutting edge, and the pressure is very large, exceeding the shear of the material being cut.

Shear strength, the molecular bond of the material is pulled apart, it is cut. Since the material is pulled apart by strong pressure, the cutting edge of the cutting tool should be very sharp.

The material itself has to bear relatively large pressure. The cutting effect is not good for soft and elastic materials, and it is more difficult for sticky materials.

The basic structure of the ultrasonic anvil-type cutting machine is similar to that of the ultrasonic cutter-type cutting machine, except that the ultrasonic output part is not a cutting knife, but a standard ultrasonic plane mold.

With. Here, the mold is equivalent to an anvil. It's just that this is a cutting board that is vibrating ultrasonically. The cutting knife still uses the traditional, any shape.

However, it's just that the sharpness of the cutting edge has been reduced, and the life of the cutter has been greatly extended.

Application

In many cases, due to the effect of ultrasound, traditional cutting blades also allow great changes. Typically, the cutter is transformed into a cylindrical shape with raised patterns

Wheels, commonly known as flower wheels. The protruding part is equivalent to the cutting edge of the cutter, and the material to be cut passes between the flower wheel and the ultrasonic cutting board. This combination can cut flowers with changes*

Patterns are very low cost and efficient. This cutting method is suitable for cutting thin-film materials, such as all kinds of trademarks, clothing lace, cloth cutting, decorative bead cutting, natural fiber

Vinyl, synthetic fiber, non-woven fabric, synthetic resin, paper, film cutting, slitting, etc.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!