loading

| Availability: | |

|---|---|

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-R35 |

| Minimum Order Quantity | 1pcs |

| Price | Negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 100 sets/month |

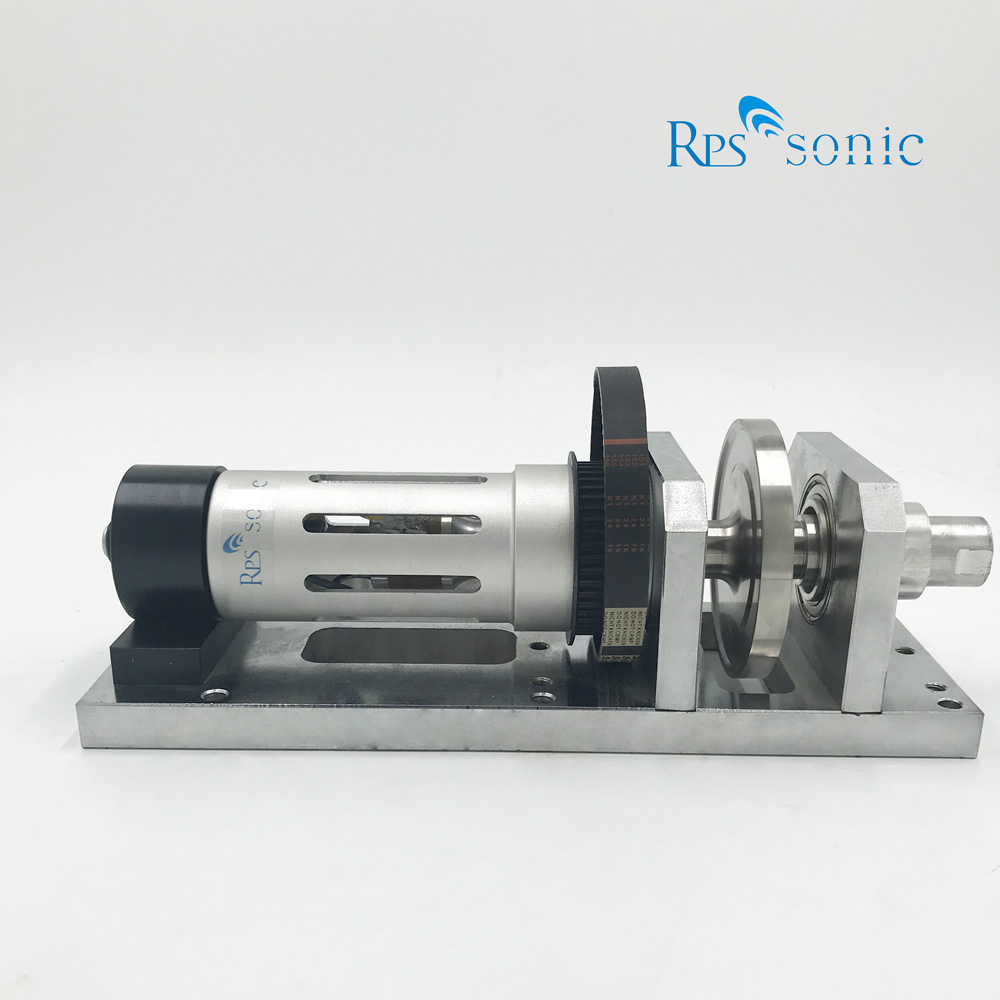

35Khz ultrasonic sewing machine part with Rotary System for fabric sealing and cutting

Parameter

| Item | Parameter | |

| Frequency | 35KHZ | |

| Power | 800 W | |

| Width of horn | 11 . 5 mm ( customized) | |

| Rotary horn diameter | 108 MM | 106 MM |

| Amplitude | 25 μm | 22 μm |

| Rotary horn material | Rapid steel | Titanium |

| Rotating speed | 3000r/min | |

| Hardness | 58-62HRC | 30 ~ 3 2HRC |

Description

The ultrasonic seamless sewing system is composed of 35k ultrasonic transducer, horn (fixed function), disc-shaped welding head and supporting special CNC power supply. The ultrasonic numerical control power supply converts the mains power into 35k high-frequency high-voltage alternating current and supplies it to the ultrasonic transducer. The ultrasonic transducer converts electrical energy into mechanical energy (ultrasonic wave), and the transducer generates vibration amplitude when it does telescopic movement in the longitudinal direction, and then transmits it to the disc-shaped welding head through the horn. So that the disc-shaped welding head is welded, and it is a complete ultrasonic cutting and sewing machine equipped with a frame, a pressure wheel and auxiliary structure and control components.

Ultrasonic bonding occurs when the materials to be joined are placed between the ultrasonic bonder’s horn and rotating wheel. High-frequency vibrations result in localized heat buildup that causes the synthetic fibers to soften and fuse, creating a durable seal.

RPS-R35 Ultrasonic Sewing Machinery is a 35khz intelligent ultrasonic welding machine and it equipped with intelligent follow-up ultrasonic generator, high-Q transducer, and wear-resistant tool head. No matter it is used in cutting, welding, and stitching. After welding sewing, the product is flat, wrinkle-free, and highly efficient. The whole size machine has speed customization, data storage, pressure adjustment, flower wheel diversity, abnormal alarm and other functions.

Applications in making non-woven bags

1. Non-woven bag seam: The use of ultrasonic welding eliminates the need for needles and threads, saves the trouble of frequent needle changes, does not have the broken joints of traditional stitching, and can also neatly cut and seal the non-woven bags. . Stitching also plays a decorative role. It has strong adhesion, can achieve waterproof effect, clear embossing, more three-dimensional relief effect on the surface, fast working speed, good product effect and high-end beauty; quality is guaranteed.

2. Making the hand strap: connect the ultrasonic lace machine and a shearing machine together, and set the ultrasonic lace machine to automatic, which can automatically make the hand strap.

Ultrasonic lace machine (semi-automatic non-woven bag machine) is widely used in packaging industry, clothing industry, beauty industry, service industry, home appliance industry, non-woven clothing, office supplies, toy industry, etc. Used to make eco-friendly bags, gift bags, shopping bags, advertising bags, non-woven bags, gift bags, non-woven handbags, non-woven clothes bags, cosmetic bags, suit bags, advertising aprons, non-woven computer covers , TV sets, air conditioner sets, washing machine sets, dust cover covers and other environmentally friendly non-woven products.

35Khz ultrasonic sewing machine part with Rotary System for fabric sealing and cutting

Parameter

| Item | Parameter | |

| Frequency | 35KHZ | |

| Power | 800 W | |

| Width of horn | 11 . 5 mm ( customized) | |

| Rotary horn diameter | 108 MM | 106 MM |

| Amplitude | 25 μm | 22 μm |

| Rotary horn material | Rapid steel | Titanium |

| Rotating speed | 3000r/min | |

| Hardness | 58-62HRC | 30 ~ 3 2HRC |

Description

The ultrasonic seamless sewing system is composed of 35k ultrasonic transducer, horn (fixed function), disc-shaped welding head and supporting special CNC power supply. The ultrasonic numerical control power supply converts the mains power into 35k high-frequency high-voltage alternating current and supplies it to the ultrasonic transducer. The ultrasonic transducer converts electrical energy into mechanical energy (ultrasonic wave), and the transducer generates vibration amplitude when it does telescopic movement in the longitudinal direction, and then transmits it to the disc-shaped welding head through the horn. So that the disc-shaped welding head is welded, and it is a complete ultrasonic cutting and sewing machine equipped with a frame, a pressure wheel and auxiliary structure and control components.

Ultrasonic bonding occurs when the materials to be joined are placed between the ultrasonic bonder’s horn and rotating wheel. High-frequency vibrations result in localized heat buildup that causes the synthetic fibers to soften and fuse, creating a durable seal.

RPS-R35 Ultrasonic Sewing Machinery is a 35khz intelligent ultrasonic welding machine and it equipped with intelligent follow-up ultrasonic generator, high-Q transducer, and wear-resistant tool head. No matter it is used in cutting, welding, and stitching. After welding sewing, the product is flat, wrinkle-free, and highly efficient. The whole size machine has speed customization, data storage, pressure adjustment, flower wheel diversity, abnormal alarm and other functions.

Applications in making non-woven bags

1. Non-woven bag seam: The use of ultrasonic welding eliminates the need for needles and threads, saves the trouble of frequent needle changes, does not have the broken joints of traditional stitching, and can also neatly cut and seal the non-woven bags. . Stitching also plays a decorative role. It has strong adhesion, can achieve waterproof effect, clear embossing, more three-dimensional relief effect on the surface, fast working speed, good product effect and high-end beauty; quality is guaranteed.

2. Making the hand strap: connect the ultrasonic lace machine and a shearing machine together, and set the ultrasonic lace machine to automatic, which can automatically make the hand strap.

Ultrasonic lace machine (semi-automatic non-woven bag machine) is widely used in packaging industry, clothing industry, beauty industry, service industry, home appliance industry, non-woven clothing, office supplies, toy industry, etc. Used to make eco-friendly bags, gift bags, shopping bags, advertising bags, non-woven bags, gift bags, non-woven handbags, non-woven clothes bags, cosmetic bags, suit bags, advertising aprons, non-woven computer covers , TV sets, air conditioner sets, washing machine sets, dust cover covers and other environmentally friendly non-woven products.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!