loading

| Availability: | |

|---|---|

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-S35 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

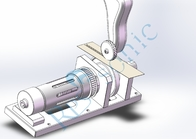

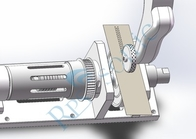

35Khz 800w Continuous Working Ultrasonic Rotary Horn For Radial Acoustic Welding

Parameter

| Item | Parameter |

| Frequency | 35Khz |

| Power | 800W |

| Ceramice chips | 4chips |

| Speed | 20m/min in max |

| Welding width | 10mm in max |

| Welding horn | 35Khz rotary horn |

| Welding type | Continues welding |

Description

A traditional sewing machine uses a needle to drive the thread to sew two pieces of cloth together. During the needle threading process, not only the cloth is pierced, but there is no bond between the cloth and the cloth, but a thin thread is used to tie them together. In this way, the cloth is easy to be pulled and the thread is easy to break. Thermoplastic fabrics can be stitched together by hot air welding. Needle and thread are not needed, but the welding temperature is not easy to control and the welding speed is slow.

Ultrasonic welding eliminates the need for needles and threads, and the trouble of frequent needle and thread changes. There is no breakage of the thread joints in traditional thread sewing, and the textiles can be neatly cut and sealed. While sewing, it also plays a decorative role, with strong adhesion, waterproof effect, clear embossing, and a more three-dimensional relief effect on the surface. The working speed is fast, the product effect is good, and it is more upscale and beautiful; the quality is guaranteed.

Textile Industry:

Seamless sewing of garments, such as lingerie, sportswear, or technical fabrics.

Hemming, cutting, and sealing fabrics for curtains, banners, and other home textiles.

Medical Industry:

Producing nonwoven items like surgical gowns, face masks, and disposable medical wear.

Packaging:

Sealing synthetic bags or pouches for food, electronics, and consumer goods.

Automotive:

Bonding or sealing interior components, such as seat covers or airbags.

No Thread or Needle:

Eliminates the need for consumables like thread, reducing costs and maintenance.

Fast and Efficient:

Processes materials quickly and seamlessly without requiring manual adjustments.

Clean and Precise:

Produces clean seams with no fraying, making it ideal for delicate or high-performance fabrics.

Eco-Friendly:

Reduces waste by eliminating the need for adhesives or other consumables.

Hygienic:

Suitable for medical and food packaging applications due to the clean bonding process.

35Khz 800w Continuous Working Ultrasonic Rotary Horn For Radial Acoustic Welding

Parameter

| Item | Parameter |

| Frequency | 35Khz |

| Power | 800W |

| Ceramice chips | 4chips |

| Speed | 20m/min in max |

| Welding width | 10mm in max |

| Welding horn | 35Khz rotary horn |

| Welding type | Continues welding |

Description

A traditional sewing machine uses a needle to drive the thread to sew two pieces of cloth together. During the needle threading process, not only the cloth is pierced, but there is no bond between the cloth and the cloth, but a thin thread is used to tie them together. In this way, the cloth is easy to be pulled and the thread is easy to break. Thermoplastic fabrics can be stitched together by hot air welding. Needle and thread are not needed, but the welding temperature is not easy to control and the welding speed is slow.

Ultrasonic welding eliminates the need for needles and threads, and the trouble of frequent needle and thread changes. There is no breakage of the thread joints in traditional thread sewing, and the textiles can be neatly cut and sealed. While sewing, it also plays a decorative role, with strong adhesion, waterproof effect, clear embossing, and a more three-dimensional relief effect on the surface. The working speed is fast, the product effect is good, and it is more upscale and beautiful; the quality is guaranteed.

Textile Industry:

Seamless sewing of garments, such as lingerie, sportswear, or technical fabrics.

Hemming, cutting, and sealing fabrics for curtains, banners, and other home textiles.

Medical Industry:

Producing nonwoven items like surgical gowns, face masks, and disposable medical wear.

Packaging:

Sealing synthetic bags or pouches for food, electronics, and consumer goods.

Automotive:

Bonding or sealing interior components, such as seat covers or airbags.

No Thread or Needle:

Eliminates the need for consumables like thread, reducing costs and maintenance.

Fast and Efficient:

Processes materials quickly and seamlessly without requiring manual adjustments.

Clean and Precise:

Produces clean seams with no fraying, making it ideal for delicate or high-performance fabrics.

Eco-Friendly:

Reduces waste by eliminating the need for adhesives or other consumables.

Hygienic:

Suitable for medical and food packaging applications due to the clean bonding process.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment