loading

| Availability: | |

|---|---|

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-LP20 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

High Power Stable 20Khz Ultrasonic Nano Dispersion Equipment

Parameter

| Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

| Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

| Power | 1000 W | 2000 W | 3000 W | 3000 W |

| Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

| Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Intensity of sound | 20 W/cm² | 40 W/cm² | 60 W/cm² | 60 W/cm² |

| Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

| Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Description

Industrial applications usually mix different liquids or solids with liquids to formulate various products. Such as: liquid beverages/pharmaceuticals, paints, coatings, detergents, etc. In order to better mix various substances into the solution, it is necessary to disperse the initially agglomerated substances into a dispersion. Ultrasonic cavitation immediately creates countless areas of high pressure and low pressure in the solution. These high-pressure and low-pressure areas continuously collide with each other to generate strong shearing force and deagglomerate the material.

1. The dispersion efficiency is high, and the efficiency can be increased by more than 200 times in the appropriate field.

2. The dispersed particles are finer, with better uniformity and stability.

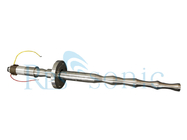

3. A snap flange is usually installed for easy movement and cleaning.

Application fields of ultrasonic dispersion of nanomaterials:

1.Nano drug preparation: Ultrasonic dispersion technology can be used to prepare nano drug carriers, such as nano drug particles, nano capsules, liposomes, etc. Ultrasonic waves can make the particle size of drug carriers smaller and more uniform, enhance the solubility and bioavailability of drugs, and are especially suitable for the dispersion of water-insoluble drugs.

2.Nano catalysts: In the preparation process of catalysts, ultrasonic waves can effectively disperse nano catalytic particles and avoid particle agglomeration, thereby increasing the surface area and reaction activity of catalysts.

3.Nano coatings and inks: When nanoparticles are used in coatings and inks, ultrasonic dispersion technology can effectively disperse pigments or other nano materials evenly and improve the stability and adhesion of the coating. It can also improve the mechanical properties, wear resistance, corrosion resistance, etc. of the coating.

4.Surface modification of nanomaterials: In the surface modification of nanomaterials, ultrasonic waves can effectively disperse surface treatment agents, improve the dispersion and surface functionalization of materials, and are widely used in conductive materials, optoelectronic materials and other fields.

5.Energy storage materials: Ultrasonic dispersion technology is widely used in the preparation of energy storage materials such as batteries and supercapacitors, which can ensure the uniform dispersion of active substances and improve the performance and stability of energy storage materials.

6.Environmental protection: In environmental pollution control, ultrasonic technology is used for the dispersion of nanomaterials and the distribution of water treatment agents, enhancing the dispersion performance of water treatment agents and improving the treatment effect.

7.Food and cosmetics: Ultrasonic technology can be used in the food and cosmetics industry to prepare nanoemulsions, such as nanoemulsified moisturizers, drug delivery systems, etc.

High Power Stable 20Khz Ultrasonic Nano Dispersion Equipment

Parameter

| Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

| Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

| Power | 1000 W | 2000 W | 3000 W | 3000 W |

| Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

| Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Intensity of sound | 20 W/cm² | 40 W/cm² | 60 W/cm² | 60 W/cm² |

| Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

| Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Description

Industrial applications usually mix different liquids or solids with liquids to formulate various products. Such as: liquid beverages/pharmaceuticals, paints, coatings, detergents, etc. In order to better mix various substances into the solution, it is necessary to disperse the initially agglomerated substances into a dispersion. Ultrasonic cavitation immediately creates countless areas of high pressure and low pressure in the solution. These high-pressure and low-pressure areas continuously collide with each other to generate strong shearing force and deagglomerate the material.

1. The dispersion efficiency is high, and the efficiency can be increased by more than 200 times in the appropriate field.

2. The dispersed particles are finer, with better uniformity and stability.

3. A snap flange is usually installed for easy movement and cleaning.

Application fields of ultrasonic dispersion of nanomaterials:

1.Nano drug preparation: Ultrasonic dispersion technology can be used to prepare nano drug carriers, such as nano drug particles, nano capsules, liposomes, etc. Ultrasonic waves can make the particle size of drug carriers smaller and more uniform, enhance the solubility and bioavailability of drugs, and are especially suitable for the dispersion of water-insoluble drugs.

2.Nano catalysts: In the preparation process of catalysts, ultrasonic waves can effectively disperse nano catalytic particles and avoid particle agglomeration, thereby increasing the surface area and reaction activity of catalysts.

3.Nano coatings and inks: When nanoparticles are used in coatings and inks, ultrasonic dispersion technology can effectively disperse pigments or other nano materials evenly and improve the stability and adhesion of the coating. It can also improve the mechanical properties, wear resistance, corrosion resistance, etc. of the coating.

4.Surface modification of nanomaterials: In the surface modification of nanomaterials, ultrasonic waves can effectively disperse surface treatment agents, improve the dispersion and surface functionalization of materials, and are widely used in conductive materials, optoelectronic materials and other fields.

5.Energy storage materials: Ultrasonic dispersion technology is widely used in the preparation of energy storage materials such as batteries and supercapacitors, which can ensure the uniform dispersion of active substances and improve the performance and stability of energy storage materials.

6.Environmental protection: In environmental pollution control, ultrasonic technology is used for the dispersion of nanomaterials and the distribution of water treatment agents, enhancing the dispersion performance of water treatment agents and improving the treatment effect.

7.Food and cosmetics: Ultrasonic technology can be used in the food and cosmetics industry to prepare nanoemulsions, such as nanoemulsified moisturizers, drug delivery systems, etc.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment