loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | RPS-Sonic |

| Certification | CE |

| Model Number | RPS-T3040-4D |

| Minimum Order Quantity | 5 sets |

| Price | negotiation |

| Packaging Details | Foam+Carton |

| Delivery Time | 2days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 200 Sets/month |

| Frequency | 40Khz | Diameter | 30mm |

|---|---|---|---|

| Ceramic Chips | 4chips | Capacitance | 5000~6000nf |

| Resistance | Less Than 30 | Amplitude | 2um |

| High Light | high power ultrasonic transducer,ultrasonic piezo transducer | ||

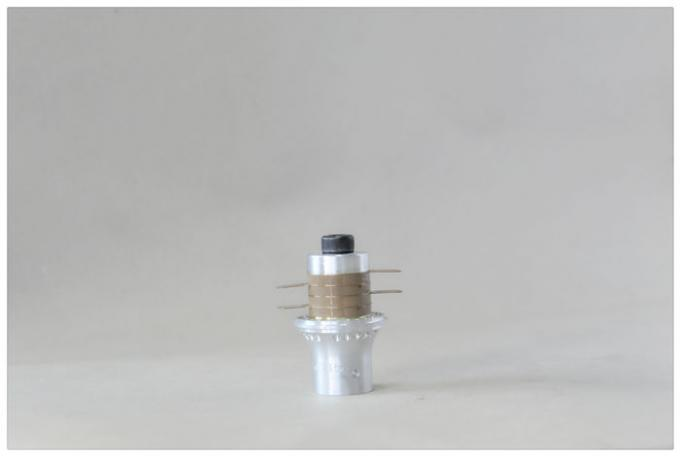

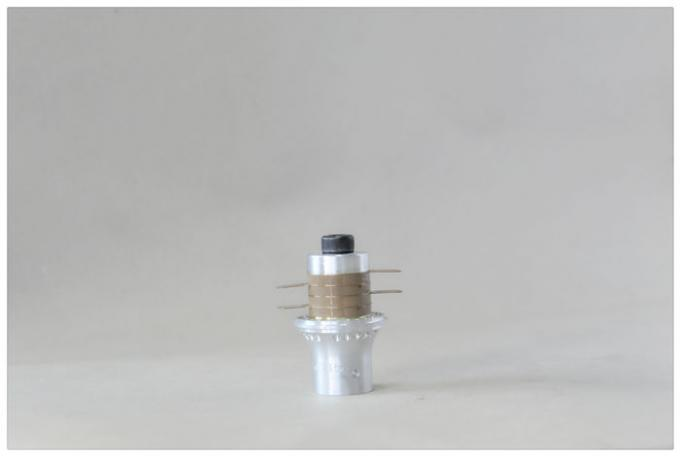

40khz Transducer For Dukane Ultrasonic Welder 43a240 Ultrasonic Generator

Ultrasonic welding is a great form of bonding technology that can streamline your manufacturing process. At RPS-SONIC we have decades of experience manufacturing high tech welding equipment, and we want to share some of the advantages ultrasonic welding with you. For many companies it represents a great way to join various different plastics, with some advantages that are hard to replicate.

First of all, Speed One of the best parts about an ultrasonic welding system is the speed that it offers. The ultrasonic horn creates a weld almost instantly, and the bonding time is determined by how quickly the weld cools. As soon as the weld is back to a normal temperature, the bond is nearly as solid as it can be. In most cases this is only a second, and for some materials even less.

For automated systems that need to achieve a high throughput, the speed that ultrasonic welding delivers is fantastic. Your production line will never have to worry about ultrasonic welding creating delays.

Naming method:

T - Transducer

50 - The outside diameter for piezoceramic ring (mm)

20 - The frequency of the transducer

4 - The number for piezoceramic ring,

D - The type of transducer D means Chinese type,B-Branson type,Z-NTK type.

Description:

1.High Efficiency: of high mechanical factor. High transfer efficiency is obtained when working in resonance frequency.

2.Big amplitude: designed and chosen by computer, high rate in oscillation speed and big amplitude in front operculum.

3.Big Power: under the function of the pre-stressed force screw rod, the piezoelectricity ceramics can work freely in the highest level of power.

4.In good heat resistance: of small resonance impedance, less heat produced, can be used in a wide range of temperature with long life and high reliability.

Specifications:

| Model | 3040-4Z |

| Connect Screw | M10 |

| Ceramic Diameter | 30 mm |

| Quantity of Ceramic | 4 pcs |

| Frequency | 40 KHz |

| Resistance | 30 Ω |

| Capacitance | 5500-6500 pF |

| Input Power | 1000 W |

| Amplitude | 2 μm |

Description:

The Replacement Converter for Branson 4TR , 4TH , 4TJ , 4TP, Direct replacement for the 40khz Branson machine.

You tell us the brand, and we can make it for you according to the brand items' No. or the original samples.

First, all of the parts are all new.

The parts are made from certified materials in tightly controlled manufacturing processes, assembled and

tested in a climate-controlled environment using carefully calibrated equipment, then properly aged and re-tested to ensure performance that duplicates the OEM part.

40Khz transducer widely ultrasonic sewing/sealing and cutting machine.Piezoelectric transducer is the electric charge that accumulates in certain solid materials in response to applied mechanical stress. It is key point of all ultrasonic equipment.The transducer decide the property of the machine.We can supply transducer, also transducer with house and booster.

Power ultrasound is used for industrial welding of plastics and bonding of minute wires in semiconductor chip manufacturing. Another industrial application is ultrasonic cleaning, also used in microsystems technology and semiconductor manufacturing.

The challenge with micro-systems cleaning is to avoid damage to tiniest structures on the surface to be cleaned. High frequencies in the range of 700 kHz to 3 MHz provide the best results without damage. With these systems, contamination particles in the nanometer range can be removed reliably without damaging the sensitive surfaces by excessive pressures and temperatures.

The ultrasonic system consists of three components: the electronic ultrasonic generator, the ultrasonic oscillator/transducer, a piezo element, and a special cleaning fluid, selected according to the cleaning task.

The ultrasonic generator converts the supplied AC current of 50/60 Hz to a frequency corresponding with the operating frequency of the transducer. The transducer in turn converts the released electric energy into mechanical acoustic oscillations causing the surrounding fluid to oscillate. Each oscillation leads to an over-pressure and low-pressure phase in the fluid, depending on whether the transducer expands or contracts. During the low-pressure phase, small cavities (cavitation bubbles) form in the fluid due to the fluid’s limited tensile strength. The bubbles implode during the over-pressure phase. When bubbles implode at the surface of the item to be cleaned, dirt particles are removed.

| Frequency | 40Khz | Diameter | 30mm |

|---|---|---|---|

| Ceramic Chips | 4chips | Capacitance | 5000~6000nf |

| Resistance | Less Than 30 | Amplitude | 2um |

| High Light | high power ultrasonic transducer,ultrasonic piezo transducer | ||

40khz Transducer For Dukane Ultrasonic Welder 43a240 Ultrasonic Generator

Ultrasonic welding is a great form of bonding technology that can streamline your manufacturing process. At RPS-SONIC we have decades of experience manufacturing high tech welding equipment, and we want to share some of the advantages ultrasonic welding with you. For many companies it represents a great way to join various different plastics, with some advantages that are hard to replicate.

First of all, Speed One of the best parts about an ultrasonic welding system is the speed that it offers. The ultrasonic horn creates a weld almost instantly, and the bonding time is determined by how quickly the weld cools. As soon as the weld is back to a normal temperature, the bond is nearly as solid as it can be. In most cases this is only a second, and for some materials even less.

For automated systems that need to achieve a high throughput, the speed that ultrasonic welding delivers is fantastic. Your production line will never have to worry about ultrasonic welding creating delays.

Naming method:

T - Transducer

50 - The outside diameter for piezoceramic ring (mm)

20 - The frequency of the transducer

4 - The number for piezoceramic ring,

D - The type of transducer D means Chinese type,B-Branson type,Z-NTK type.

Description:

1.High Efficiency: of high mechanical factor. High transfer efficiency is obtained when working in resonance frequency.

2.Big amplitude: designed and chosen by computer, high rate in oscillation speed and big amplitude in front operculum.

3.Big Power: under the function of the pre-stressed force screw rod, the piezoelectricity ceramics can work freely in the highest level of power.

4.In good heat resistance: of small resonance impedance, less heat produced, can be used in a wide range of temperature with long life and high reliability.

Specifications:

| Model | 3040-4Z |

| Connect Screw | M10 |

| Ceramic Diameter | 30 mm |

| Quantity of Ceramic | 4 pcs |

| Frequency | 40 KHz |

| Resistance | 30 Ω |

| Capacitance | 5500-6500 pF |

| Input Power | 1000 W |

| Amplitude | 2 μm |

Description:

The Replacement Converter for Branson 4TR , 4TH , 4TJ , 4TP, Direct replacement for the 40khz Branson machine.

You tell us the brand, and we can make it for you according to the brand items' No. or the original samples.

First, all of the parts are all new.

The parts are made from certified materials in tightly controlled manufacturing processes, assembled and

tested in a climate-controlled environment using carefully calibrated equipment, then properly aged and re-tested to ensure performance that duplicates the OEM part.

40Khz transducer widely ultrasonic sewing/sealing and cutting machine.Piezoelectric transducer is the electric charge that accumulates in certain solid materials in response to applied mechanical stress. It is key point of all ultrasonic equipment.The transducer decide the property of the machine.We can supply transducer, also transducer with house and booster.

Power ultrasound is used for industrial welding of plastics and bonding of minute wires in semiconductor chip manufacturing. Another industrial application is ultrasonic cleaning, also used in microsystems technology and semiconductor manufacturing.

The challenge with micro-systems cleaning is to avoid damage to tiniest structures on the surface to be cleaned. High frequencies in the range of 700 kHz to 3 MHz provide the best results without damage. With these systems, contamination particles in the nanometer range can be removed reliably without damaging the sensitive surfaces by excessive pressures and temperatures.

The ultrasonic system consists of three components: the electronic ultrasonic generator, the ultrasonic oscillator/transducer, a piezo element, and a special cleaning fluid, selected according to the cleaning task.

The ultrasonic generator converts the supplied AC current of 50/60 Hz to a frequency corresponding with the operating frequency of the transducer. The transducer in turn converts the released electric energy into mechanical acoustic oscillations causing the surrounding fluid to oscillate. Each oscillation leads to an over-pressure and low-pressure phase in the fluid, depending on whether the transducer expands or contracts. During the low-pressure phase, small cavities (cavitation bubbles) form in the fluid due to the fluid’s limited tensile strength. The bubbles implode during the over-pressure phase. When bubbles implode at the surface of the item to be cleaned, dirt particles are removed.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!