loading

| Availability: | |

|---|---|

| Quantity: | |

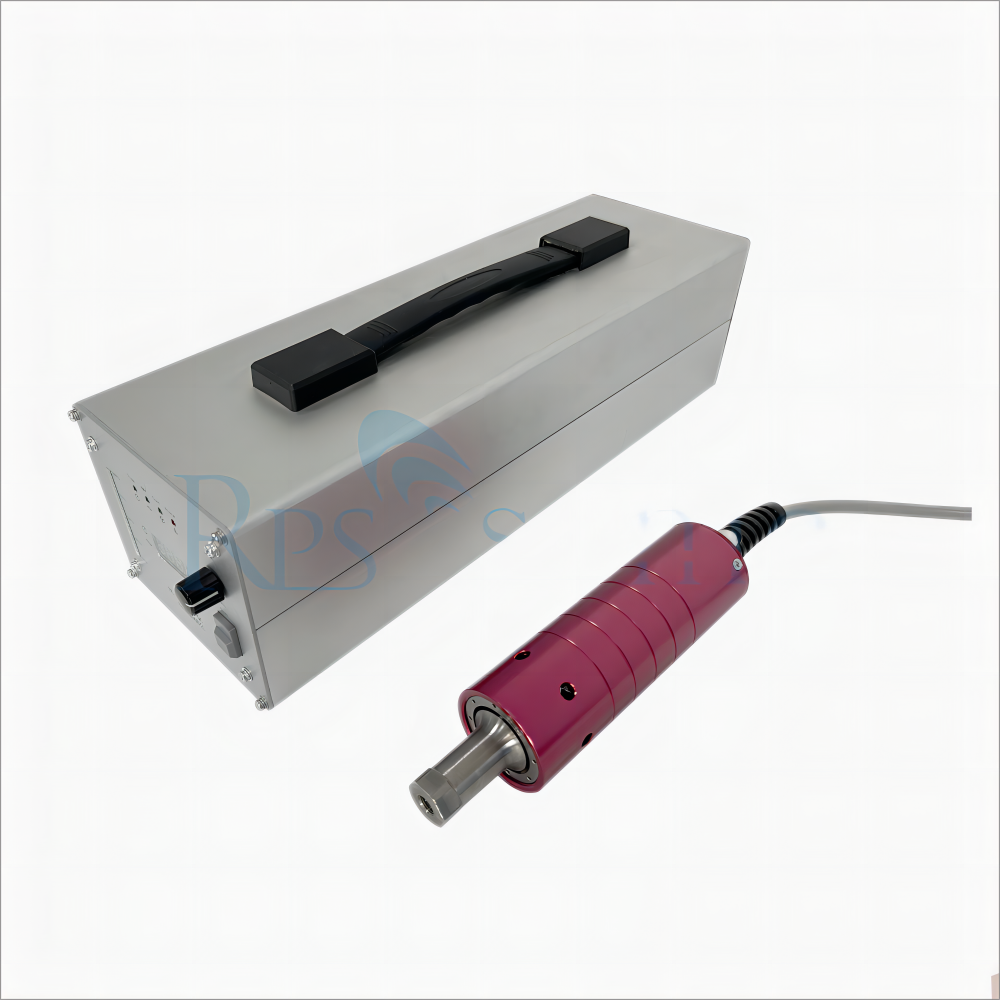

RPS-SW35

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-2000 |

| Minimum Order Quantity | 1set |

| Price | negotiation |

| Packaging Details | FOAM AND CARTON |

| Delivery Time | 3DAYS |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 200 SETS PER MONTH |

| Frequency | 15K~60K | Power | 300W~3000W |

|---|---|---|---|

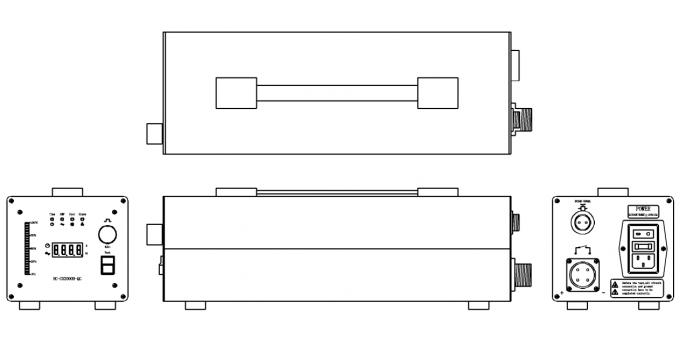

| Type | Digital Generator | Size | 120*120*380 |

| Weight | 3.3Kg | Certification | SGS |

| High Light | digital ultrasonic generator,ultrasonic frequency generator | ||

Min size:120*120*380

The paper presents a new type of high power ultrasonic generator for welding and cutting processes developed by the Tele & Radio Research Institute. The new generator can provide up to 4 kW of electrical power to an ultrasonic transducer in the frequency range of 15 kHz up to 60 kHz with regulation step down to 0.1 Hz. The device utilizes an innovative microcontroller with built-in high resolution timing blocks that enable direct synthesis of control signals for the generator's resonant converter, without the need of an external DDS unit or programmable device. This new approach to designing ultrasonic generators can benefit in greater flexibility and reliability of the device. New algorithms with cycle-by-cycle parameter control, and precise regulation of output frequency and power delivery, have been developed.

Various parameters of ultrasonic stack, such as impedance and resonant frequency, are measured by the generator in real-time, and can be used for ultrasonic stack wear monitoring and fault detection.

This digital generator is available in frequencies of 15kHz, 20Khz, 28Khz,30 kHz, 35 kHz and 40Khz at a power range between 300 W and 3000 W. Programmable ramp up and ramp down times and infinitely variable adjustment of weld amplitudes are only some of the features of this product line. The biggest advantage of this generator is the wide frenquncy range, for example: the 20Khz generator, it can catch the frequency from 18~21khz, so it is easy to tuning. Also it is easy for some ultrasonic new user.

100% digital control of all power supply functions and parameters allows for unique configurations and future upgrades or requirements. Includes digital frequency syntheses

Industry leading data acquisition rate speed of .5 ms due to advanced multi-core architecture. Increased weld accuracy and repeatability.

Digi-Trac tuning automatically tracks the resonant frequency digitally. Adjust the output frequency to match the acoustic stack (sonotrode, booster, and transducer) this is done for every weld cycle and eliminates the need to manually tune the generator.

Ultrasonic overload protection, with status indicator for ease of troubleshooting. The overload power limit is based on true RMS power output level.

Line Voltage Regulation compensates for line fluctuations assuring consistent amplitude.

1, Adopt parallel resonance to drive the converter, reduce the heating of converter to protect it.

2, Button start, easy operation.

3, Imported control chip and driver, makes the ultrasonic generator works more reliable.

4,The frequency based on the PID control and amplitude control, frequency locking and achieve constant amplitude control as well.

5, Explosive power output,compare to traditional ultrasonic generator, our ultrasonic generator only request 1/2 cylinder pressure to achieve the same power output.

6, Amplitude soft start, ensure make use of huge mould.

7, Welding amplitude adjustment range 0~100% by 1%.

8, Multiple protection to ensure the safety of equipment and test-piece.

| Ultrasonic generator technical specification | |||||||||

| Model | 15kHz | 20 kHz | 30 kHz | 35 kHz | 40 kHz | ||||

| Operating environment | -20℃~+80℃, humidity less 70% | ||||||||

| Dimension | Length 350mm, Width 12mm, Height 100mm | ||||||||

| Matched converter | 15kHz | 20kHz | 30kHz | 35kHz | 40kHz | ||||

| Power | 2200W/3200W | 2000W/2600W | 800W/1500W | 800W/1200W | 500W/800W | ||||

Material | Shell: aluminum alloy,

Panel: 304 stainless steel, Heating panel: 6061 pure aluminum | ||||||||

| Voltage | 220VAC, 50/60HZ | ||||||||

| Standard parts | Ultrasonic generator, converter wire, power wire, control signal interface, DB9 core wire. | ||||||||

| Optional part | Shockproof suitcase | ||||||||

| Application | Suitable |

Welding | Available |

| Sealing | Available |

| Sewing | Available |

| Cutting | Available |

| Sonochemistry | Available , but not the best, If open the equipment when the horn in the liquid , it can catch the frequency well, it is better tracking the frequency without any loading. |

| Metal welding | Available , but not the best. Metal welding always in high loading , it is better use a generator with well ventilation. |

| Atomization | Available |

Available environment temperature: -20C° to 40°C, work over temperature may cause in abnormal operation of the equipment and safety accidents.

Available air humidity: less than 70%. Excessive air humidity may cause Short circuit of the internal electronic components.

Maximum electromagnetic interference intensity: less than 120E. Larger than 120E will cause seriously interfere and damage the equipment.

The power input standard is: single-phase AC220V 50HZ/60HZ.

Input power supply voltage fluctuation range: <10%.

Input power supply harmonic content: <20%.

Input power supply current: 10A.

Input power cord diameter: >1.5MM2.

Advantages

1. DDS and PID high precision frequency control core.

2. Electric constant amplitude control system.

3. Welding amplitude setting range 0% - 100% by 1%.

4. Soft start, setting range 0-999MS, setprecison 1MS.

5. Three self-checking modes.

6. Pressure trigger/Time/Energy welding modes.

7. Six protections.

8. Less space, total weight 3.3KG.

| Frequency | 15K~60K | Power | 300W~3000W |

|---|---|---|---|

| Type | Digital Generator | Size | 120*120*380 |

| Weight | 3.3Kg | Certification | SGS |

| High Light | digital ultrasonic generator,ultrasonic frequency generator | ||

Min size:120*120*380

The paper presents a new type of high power ultrasonic generator for welding and cutting processes developed by the Tele & Radio Research Institute. The new generator can provide up to 4 kW of electrical power to an ultrasonic transducer in the frequency range of 15 kHz up to 60 kHz with regulation step down to 0.1 Hz. The device utilizes an innovative microcontroller with built-in high resolution timing blocks that enable direct synthesis of control signals for the generator's resonant converter, without the need of an external DDS unit or programmable device. This new approach to designing ultrasonic generators can benefit in greater flexibility and reliability of the device. New algorithms with cycle-by-cycle parameter control, and precise regulation of output frequency and power delivery, have been developed.

Various parameters of ultrasonic stack, such as impedance and resonant frequency, are measured by the generator in real-time, and can be used for ultrasonic stack wear monitoring and fault detection.

This digital generator is available in frequencies of 15kHz, 20Khz, 28Khz,30 kHz, 35 kHz and 40Khz at a power range between 300 W and 3000 W. Programmable ramp up and ramp down times and infinitely variable adjustment of weld amplitudes are only some of the features of this product line. The biggest advantage of this generator is the wide frenquncy range, for example: the 20Khz generator, it can catch the frequency from 18~21khz, so it is easy to tuning. Also it is easy for some ultrasonic new user.

100% digital control of all power supply functions and parameters allows for unique configurations and future upgrades or requirements. Includes digital frequency syntheses

Industry leading data acquisition rate speed of .5 ms due to advanced multi-core architecture. Increased weld accuracy and repeatability.

Digi-Trac tuning automatically tracks the resonant frequency digitally. Adjust the output frequency to match the acoustic stack (sonotrode, booster, and transducer) this is done for every weld cycle and eliminates the need to manually tune the generator.

Ultrasonic overload protection, with status indicator for ease of troubleshooting. The overload power limit is based on true RMS power output level.

Line Voltage Regulation compensates for line fluctuations assuring consistent amplitude.

1, Adopt parallel resonance to drive the converter, reduce the heating of converter to protect it.

2, Button start, easy operation.

3, Imported control chip and driver, makes the ultrasonic generator works more reliable.

4,The frequency based on the PID control and amplitude control, frequency locking and achieve constant amplitude control as well.

5, Explosive power output,compare to traditional ultrasonic generator, our ultrasonic generator only request 1/2 cylinder pressure to achieve the same power output.

6, Amplitude soft start, ensure make use of huge mould.

7, Welding amplitude adjustment range 0~100% by 1%.

8, Multiple protection to ensure the safety of equipment and test-piece.

| Ultrasonic generator technical specification | |||||||||

| Model | 15kHz | 20 kHz | 30 kHz | 35 kHz | 40 kHz | ||||

| Operating environment | -20℃~+80℃, humidity less 70% | ||||||||

| Dimension | Length 350mm, Width 12mm, Height 100mm | ||||||||

| Matched converter | 15kHz | 20kHz | 30kHz | 35kHz | 40kHz | ||||

| Power | 2200W/3200W | 2000W/2600W | 800W/1500W | 800W/1200W | 500W/800W | ||||

Material | Shell: aluminum alloy,

Panel: 304 stainless steel, Heating panel: 6061 pure aluminum | ||||||||

| Voltage | 220VAC, 50/60HZ | ||||||||

| Standard parts | Ultrasonic generator, converter wire, power wire, control signal interface, DB9 core wire. | ||||||||

| Optional part | Shockproof suitcase | ||||||||

| Application | Suitable |

Welding | Available |

| Sealing | Available |

| Sewing | Available |

| Cutting | Available |

| Sonochemistry | Available , but not the best, If open the equipment when the horn in the liquid , it can catch the frequency well, it is better tracking the frequency without any loading. |

| Metal welding | Available , but not the best. Metal welding always in high loading , it is better use a generator with well ventilation. |

| Atomization | Available |

Available environment temperature: -20C° to 40°C, work over temperature may cause in abnormal operation of the equipment and safety accidents.

Available air humidity: less than 70%. Excessive air humidity may cause Short circuit of the internal electronic components.

Maximum electromagnetic interference intensity: less than 120E. Larger than 120E will cause seriously interfere and damage the equipment.

The power input standard is: single-phase AC220V 50HZ/60HZ.

Input power supply voltage fluctuation range: <10%.

Input power supply harmonic content: <20%.

Input power supply current: 10A.

Input power cord diameter: >1.5MM2.

Advantages

1. DDS and PID high precision frequency control core.

2. Electric constant amplitude control system.

3. Welding amplitude setting range 0% - 100% by 1%.

4. Soft start, setting range 0-999MS, setprecison 1MS.

5. Three self-checking modes.

6. Pressure trigger/Time/Energy welding modes.

7. Six protections.

8. Less space, total weight 3.3KG.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment