loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-W20-800 |

| Minimum Order Quantity | 1SET |

| Price | negotiation |

| Packaging Details | FOAM AND CARTON |

| Delivery Time | 3DYAS |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 200 SET PER MONTH |

| Name | Ultrasonic Assisted Threaded Inserts | Frequency | 20Khz |

|---|---|---|---|

| Power | 2000W | Install Type | Auto |

| Generator | Digital | Weight | 60Kg |

| Horn | Customized | ||

| High Light | ultrasonic hand welder,ultrasonic welding gun | ||

Ultrasonic assisther threased insert equipment Great for Thermoplastics material and with High overall performance.

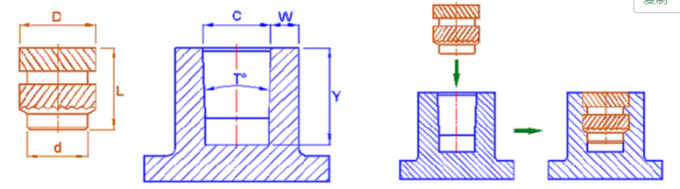

Similarly, ultrasonics can be applied to melt a border zone in the hole. Instead of heat, the ultrasonic process creates a vibration frequency that melts the plastic. It is comparable in speed with heat staking but requires precise control, and can create a larger process-affected zone that can result in chipping of the material. The ultrasonic process can also be loud and more difficult to automate, which is why it is less likely to be used, particularly by shops not already doing ultrasonic welding.

20KHz Ultrasonic plastic welding machine:

1, Automatic frequency tracking functions.

2. Automatically detect and display.

3, Five-step adjustable amplitude without replacement increases, you can weld various plastics.

4. Control time accuracy up to 0.001 seconds.

5, Weld Mode :Time mode

6. Adoption of the internal signal output/direct and automatic matching of mechanical systems.

7, Department of mechanical combination output, convenient automatic match.

8, The original German (PINOT) automatic constant amplitude

9.The complete machine adopts fittings: original imported Germany (PINOT) transducer, battery valve (Germany FESTO), pressure gauge (FESTO), linear cross Rails (ITO), cylinder (Germany FESTO), pressure regulating valve (Germany FESTO), header (Japanese SMC) program (OMRON), filters (SMC), PLC (Japan PANASONIC), man-machine interface

| Model | output power | Frequency | voltage | journey | oscillatory system | output time | ||||

| AS006 | 2000W | 20KHz | 220V | 100mm | automatic balancing circuit | “Germany”time0.001-9.999S | ||||

| air pressure | Vibrating head cold system | welding area(mm) | AIR COMPRESSOR | Dimensions(mm) | Net weight | |||||

| pressure range1-7bar | cooling wind | 180 | 2HP | 650*420*1300 | 120Kg | |||||

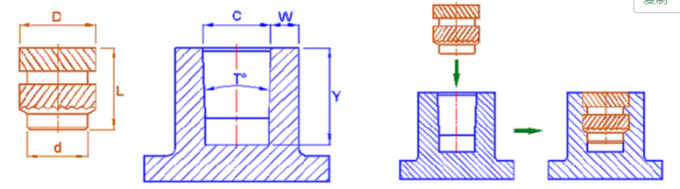

| Tapered, thru threaded inserts, types IUA (aluminum inserts), IUB (brass inserts) and IUC (stainless steel inserts) are designed for use in tapered holes. A tapered mounting hole allows for rapid and accurate alignment prior to installation. | Straight wall, thru threaded inserts, types IUTA (aluminum inserts), IUTB (brass inserts) and IUTC (stainless steel inserts) are designed for use in straight holes. Self-aligning lead-in of inserts provides for accurate alignment prior to installation. |

| Symmetrical, thru threaded inserts, types ISA (aluminum inserts), ISB (brass inserts) and ISC (stainless steel inserts) are designed for use in straight or tapered holes. Symmetrical design eliminates the need for orientation. | Threads as small as M1, designed for use in straight or tapered holes. Symmetrical design eliminates need for orientation and provides excellent performance in a wide range of plastics. Available in aluminum or brass. |

| Name | Ultrasonic Assisted Threaded Inserts | Frequency | 20Khz |

|---|---|---|---|

| Power | 2000W | Install Type | Auto |

| Generator | Digital | Weight | 60Kg |

| Horn | Customized | ||

| High Light | ultrasonic hand welder,ultrasonic welding gun | ||

Ultrasonic assisther threased insert equipment Great for Thermoplastics material and with High overall performance.

Similarly, ultrasonics can be applied to melt a border zone in the hole. Instead of heat, the ultrasonic process creates a vibration frequency that melts the plastic. It is comparable in speed with heat staking but requires precise control, and can create a larger process-affected zone that can result in chipping of the material. The ultrasonic process can also be loud and more difficult to automate, which is why it is less likely to be used, particularly by shops not already doing ultrasonic welding.

20KHz Ultrasonic plastic welding machine:

1, Automatic frequency tracking functions.

2. Automatically detect and display.

3, Five-step adjustable amplitude without replacement increases, you can weld various plastics.

4. Control time accuracy up to 0.001 seconds.

5, Weld Mode :Time mode

6. Adoption of the internal signal output/direct and automatic matching of mechanical systems.

7, Department of mechanical combination output, convenient automatic match.

8, The original German (PINOT) automatic constant amplitude

9.The complete machine adopts fittings: original imported Germany (PINOT) transducer, battery valve (Germany FESTO), pressure gauge (FESTO), linear cross Rails (ITO), cylinder (Germany FESTO), pressure regulating valve (Germany FESTO), header (Japanese SMC) program (OMRON), filters (SMC), PLC (Japan PANASONIC), man-machine interface

| Model | output power | Frequency | voltage | journey | oscillatory system | output time | ||||

| AS006 | 2000W | 20KHz | 220V | 100mm | automatic balancing circuit | “Germany”time0.001-9.999S | ||||

| air pressure | Vibrating head cold system | welding area(mm) | AIR COMPRESSOR | Dimensions(mm) | Net weight | |||||

| pressure range1-7bar | cooling wind | 180 | 2HP | 650*420*1300 | 120Kg | |||||

| Tapered, thru threaded inserts, types IUA (aluminum inserts), IUB (brass inserts) and IUC (stainless steel inserts) are designed for use in tapered holes. A tapered mounting hole allows for rapid and accurate alignment prior to installation. | Straight wall, thru threaded inserts, types IUTA (aluminum inserts), IUTB (brass inserts) and IUTC (stainless steel inserts) are designed for use in straight holes. Self-aligning lead-in of inserts provides for accurate alignment prior to installation. |

| Symmetrical, thru threaded inserts, types ISA (aluminum inserts), ISB (brass inserts) and ISC (stainless steel inserts) are designed for use in straight or tapered holes. Symmetrical design eliminates the need for orientation. | Threads as small as M1, designed for use in straight or tapered holes. Symmetrical design eliminates need for orientation and provides excellent performance in a wide range of plastics. Available in aluminum or brass. |

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!