loading

| Availability: | |

|---|---|

| Quantity: | |

RPS-SW35

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-TS20 |

| Minimum Order Quantity | 1 |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 5 WORK DAYS |

| Payment Terms | T/T |

| Supply Ability | 100SET/,YEAR |

| Frequency | 28Khz | Power | 800W |

|---|---|---|---|

| Generator | Digital Generator | Suitable Apply | Medical Hose, Cosmetic Hose,Toothpaste Tube |

| Horn | Aluminum Alloy, Titanium Alloy, Steel | Suitable Material | All Thermoplastic Tube |

| High Light | ultrasonic hand welder,ultrasonic welding gun | ||

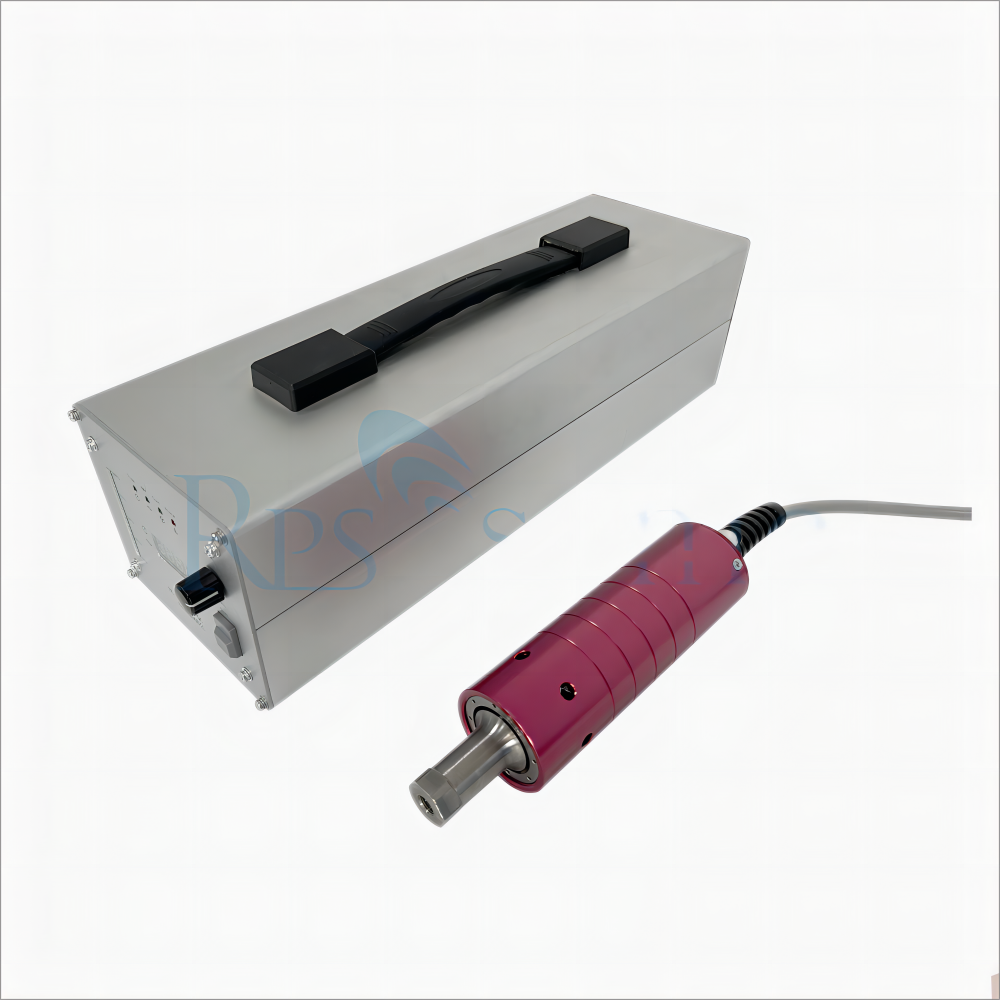

Ultrasonic placstic tube sealing equipment combined by ultrasonic generator, ultrasonic transducer booster& horn, horn need be customized depending on your requirement.

The plastic inside the tube is heated and melted by high frequency friction force introduced from ultrasonic horn. Clamps closed and cooled and formed the melted plastic to seal the tube. This methos is suitable for production of small to medium capacity.

Advantages:

Only contacted areas are heated. The physical and chemical characteristics of inner filling are still remained.

Sealed area is flat; over-melting phenomenon is contrlled.

With high frequency oscillation from ultrasonic, the liquid, oil, filling or plastic waste at sealing area is driven away. Sealing effect is more reliable

to initiate the weld cycle. Air is directed into cylinders to advance the weld anvil and ultrasonic horn towards the center line of the tube. The tube is closed to a preset gap and held for the applicationof sonic energy.

An ultrasonic power supply takes the 50/60 Hz electrical energy and converts it to 20,000 cycles

per second thorough a power oscillator. This high frequency electrical energy is applied to the convertor which transforms the electrical current to high frequency mechanical vibrations. The sonic energy causes the horn to vibrate against the tube end at 20,000 cycles per second.

Advantages of Ultrasonic Sealing

• Universal: Adapts to virtually all filling machine styles. Seals both plastic and laminates tubes

• Fast: Seals up to 60 tubes per minute

• Reliable: Maintains high seal strength even when sealing through product overflow and contaminant’s.

• Economical: No time lost waiting for machine warm-up. Requires minimal electrical power.

• Compact: Actuator and power supply require minimal space.

• Clean:The intense vibration disperses contamination from the seal area and generates heat to bond the materials.

| Item | parameter |

| Frequency | 20Khz |

| Power | 2000W in max |

| Generator | digital generator |

| Voltage | 220-240V 50/60 Hz |

| Horn material | Aluminum alloy, titanium alloy, steel |

| Application | Medical plasctic tube, cosmetic plastic tube Toothpaste tube |

| Seal tube dia | 5-80mm(can customed) |

1.Min order quantity:1 set

2. Payment terms :100%TT

3.Delivery time:7 days after confirming the order

4.Packaging :In export carton covered with damp proof film

5.One year quality guarantee,lifelong maintenance.

![]()

| Frequency | 28Khz | Power | 800W |

|---|---|---|---|

| Generator | Digital Generator | Suitable Apply | Medical Hose, Cosmetic Hose,Toothpaste Tube |

| Horn | Aluminum Alloy, Titanium Alloy, Steel | Suitable Material | All Thermoplastic Tube |

| High Light | ultrasonic hand welder,ultrasonic welding gun | ||

Ultrasonic placstic tube sealing equipment combined by ultrasonic generator, ultrasonic transducer booster& horn, horn need be customized depending on your requirement.

The plastic inside the tube is heated and melted by high frequency friction force introduced from ultrasonic horn. Clamps closed and cooled and formed the melted plastic to seal the tube. This methos is suitable for production of small to medium capacity.

Advantages:

Only contacted areas are heated. The physical and chemical characteristics of inner filling are still remained.

Sealed area is flat; over-melting phenomenon is contrlled.

With high frequency oscillation from ultrasonic, the liquid, oil, filling or plastic waste at sealing area is driven away. Sealing effect is more reliable

to initiate the weld cycle. Air is directed into cylinders to advance the weld anvil and ultrasonic horn towards the center line of the tube. The tube is closed to a preset gap and held for the applicationof sonic energy.

An ultrasonic power supply takes the 50/60 Hz electrical energy and converts it to 20,000 cycles

per second thorough a power oscillator. This high frequency electrical energy is applied to the convertor which transforms the electrical current to high frequency mechanical vibrations. The sonic energy causes the horn to vibrate against the tube end at 20,000 cycles per second.

Advantages of Ultrasonic Sealing

• Universal: Adapts to virtually all filling machine styles. Seals both plastic and laminates tubes

• Fast: Seals up to 60 tubes per minute

• Reliable: Maintains high seal strength even when sealing through product overflow and contaminant’s.

• Economical: No time lost waiting for machine warm-up. Requires minimal electrical power.

• Compact: Actuator and power supply require minimal space.

• Clean:The intense vibration disperses contamination from the seal area and generates heat to bond the materials.

| Item | parameter |

| Frequency | 20Khz |

| Power | 2000W in max |

| Generator | digital generator |

| Voltage | 220-240V 50/60 Hz |

| Horn material | Aluminum alloy, titanium alloy, steel |

| Application | Medical plasctic tube, cosmetic plastic tube Toothpaste tube |

| Seal tube dia | 5-80mm(can customed) |

1.Min order quantity:1 set

2. Payment terms :100%TT

3.Delivery time:7 days after confirming the order

4.Packaging :In export carton covered with damp proof film

5.One year quality guarantee,lifelong maintenance.

![]()

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!