loading

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | ISO-9001 |

| Model Number | RPS-Σ3000M |

| Minimum Order Quantity | 1 |

| Price | negotiation |

| Packaging Details | wood box |

| Delivery Time | 7 days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 100 sets/month |

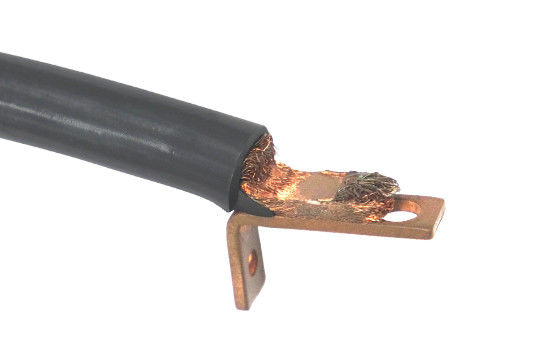

| Name | Ultrasonic Welding Machine | Application | Metal Welding |

|---|---|---|---|

| Frequency | 20Khz | Power | 2000-5000W |

| Voltage | 220V/50~60HZ | Warranty | 1 Year |

| High Light | 20khz Ultrasonic Welding Equipment,ultrasonic welder 20khz | ||

The Ultrasonic Metal Welding Machine Σ3000M Series is a complete ultrasonic welding device that integrates ultrasonic digital generators and controllers with ultrasonic welding presses. The Σ3000M series has a variety of welding modes to meet customers' more stringent welding requirements.

Ultrasonic welding machine with modes of time model and engry model, it can automatically track and display real-time frequency, with amplitude stepping function, welding amplitude range up to 10-100(1%accuracy). There is also amplitude compensation; welding quality management (time,energy mutual detection), including clear traceable welding records (operation statistics) to control your welding quality in real time. It also features transducer overload protection, mold impedance analysis and protection to protect your equipment. Powerful, high quality and high welding stability.

*Full range of modular design

*High-strength rigid structure

*Digital ultrasonic generator

*Maximum pressure 1000N

| Auto parts | bumpers, air filters, car audios, foot pads, door panels, clutch forks |

| Electric products | humidifiers, chargers, storage battery, telephones, sockets, flash discs |

| Medical products | leucocyte filters, accurate liquid medicine filters, blood plasma separating cups |

| Packaging and clothing | valve bags, paper cups, dairy food packing cases, bag belts, zippers |

| Stationery and toy | ink boxes, file folders, name card holders, albums |

| Σ3000M | 20Khz | 20Khz |

| Power | 2000W/3000W | 4000W/5000W |

| Pressure | 3000N | 3000N |

| Power Input | 2000W/10A 3000W/15A AC 220V +10% 50/60Hz | 4000W,5000W/15A AC 220V +10% 50/60Hz |

| Electric Box Size | 2000W/420mm×211mm×185mm 3000W/465mm×211mm×185mm | 465mm×211mm×185mm |

| Electric Box Weight | 10KG | 11.76KG |

| Machine Size | 747mm×467mm×581mm | 792mm×467mm×581mm |

| Machine Weight | 64.5KG | 66.2KG |

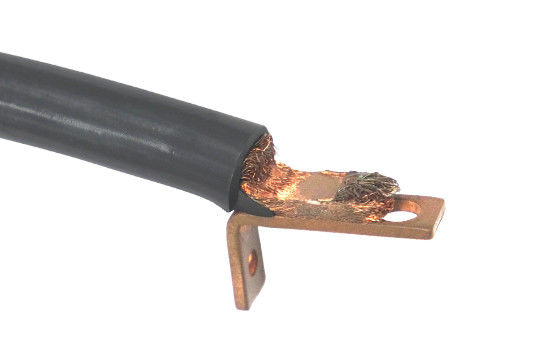

| Name | Ultrasonic Welding Machine | Application | Metal Welding |

|---|---|---|---|

| Frequency | 20Khz | Power | 2000-5000W |

| Voltage | 220V/50~60HZ | Warranty | 1 Year |

| High Light | 20khz Ultrasonic Welding Equipment,ultrasonic welder 20khz | ||

The Ultrasonic Metal Welding Machine Σ3000M Series is a complete ultrasonic welding device that integrates ultrasonic digital generators and controllers with ultrasonic welding presses. The Σ3000M series has a variety of welding modes to meet customers' more stringent welding requirements.

Ultrasonic welding machine with modes of time model and engry model, it can automatically track and display real-time frequency, with amplitude stepping function, welding amplitude range up to 10-100(1%accuracy). There is also amplitude compensation; welding quality management (time,energy mutual detection), including clear traceable welding records (operation statistics) to control your welding quality in real time. It also features transducer overload protection, mold impedance analysis and protection to protect your equipment. Powerful, high quality and high welding stability.

*Full range of modular design

*High-strength rigid structure

*Digital ultrasonic generator

*Maximum pressure 1000N

| Auto parts | bumpers, air filters, car audios, foot pads, door panels, clutch forks |

| Electric products | humidifiers, chargers, storage battery, telephones, sockets, flash discs |

| Medical products | leucocyte filters, accurate liquid medicine filters, blood plasma separating cups |

| Packaging and clothing | valve bags, paper cups, dairy food packing cases, bag belts, zippers |

| Stationery and toy | ink boxes, file folders, name card holders, albums |

| Σ3000M | 20Khz | 20Khz |

| Power | 2000W/3000W | 4000W/5000W |

| Pressure | 3000N | 3000N |

| Power Input | 2000W/10A 3000W/15A AC 220V +10% 50/60Hz | 4000W,5000W/15A AC 220V +10% 50/60Hz |

| Electric Box Size | 2000W/420mm×211mm×185mm 3000W/465mm×211mm×185mm | 465mm×211mm×185mm |

| Electric Box Weight | 10KG | 11.76KG |

| Machine Size | 747mm×467mm×581mm | 792mm×467mm×581mm |

| Machine Weight | 64.5KG | 66.2KG |

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!