loading

| Availability: | |

|---|---|

| Quantity: | |

RPS-SONO20

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-C30-50 |

| Minimum Order Quantity | 1set |

| Packaging Details | wooden box |

| Reactor Type | Stailess Steel U Shape Pipe | Horn Material | Titanium |

|---|---|---|---|

| Frequency | 20Khz | Capacity | 50L |

| Function | Graphene Dispersion,pigment Dispersion | Ultrasonic Cavitation Intensity | 3.0-4.5(w/cm²) |

| High Light | Titanium Horn Ultrasonic Dispersion Equipment,U Shaped Pipe Dispersion Equipment,20Khz Ultrasonic Liquid Processor | ||

Stainless Steel U Shaped Pipe Ultrasonic Graphene Dispersion Equipment 50L

Ultrasonic Graphene Dispersion Machine 50L Stainless Steel U Shaped Pipe Improve Efficiency Up To 200 Times

Product Descripiton:

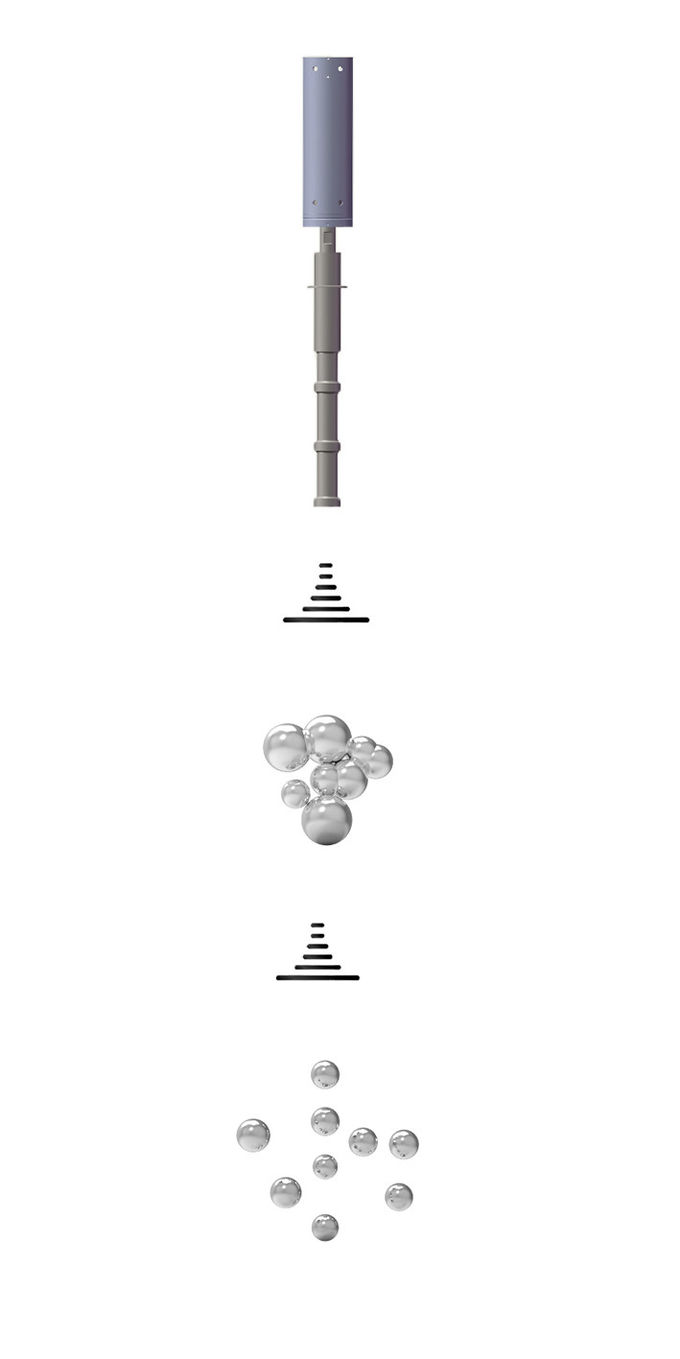

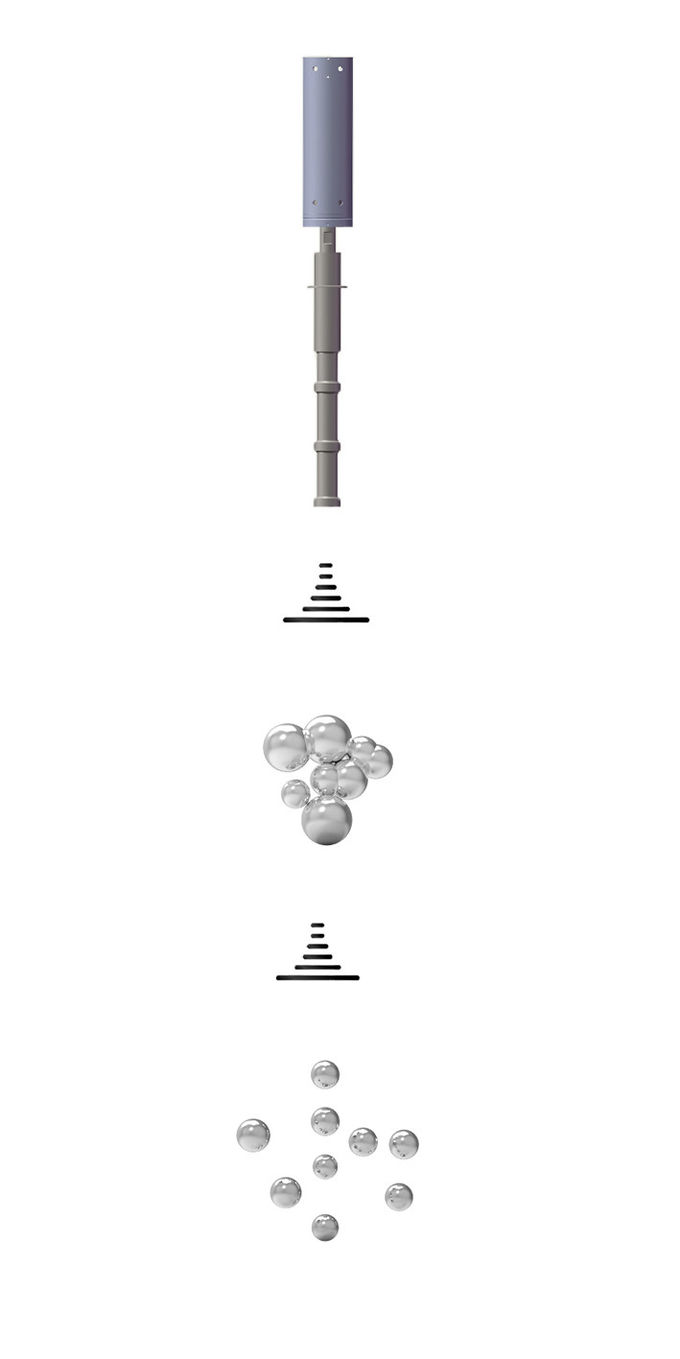

The power of ultrasonic affects the efficiency of stripping graphite oxide into graphene oxide and the transverse size of graphene oxide. The higher the power is, the higher the efficiency is. Compared with the way of ultrasonic grinding, that is, direct action stripping, ultrasonic cleaning, that is, indirect action stripping, has less damage to the transverse size of graphite oxide, and can obtain graphene oxide with larger transverse size.

Graphene nanobelts were prepared from single-walled carbon nanotubes by gas-phase oxidation and ultrasonic pyrolysis. The morphology and structure of the prepared graphene nanobelts were analyzed by transmission electron microscopy (TEM), atomic force microscopy (AFM) and Raman spectroscopy (Raman). The results show that the width of graphene nanobelts prepared by Hannover instrument ultrasonic processor is narrow, the edge is smooth, and compared with the rigid single-walled carbon nanotubes, they have good flexibility. The thickness of about 2 nm also indicates the double-layer structure of graphene nanobelts. In the process of gas phase oxidation and ultrasonic pyrolysis, the ratio of D peak to G peak in Raman spectrum is always about 0.15, which indicates that no new defects are introduced in the whole preparation process.

Compared with other methods, the nanobelts prepared by RPS-SONIC ultrasonic processor have the advantages of high crystallinity, narrow width and smooth edge

Ultrasonic-assisted liquid phase exfoliation greatly improves the efficiency of graphene extraction.The application of ultrasonic equipment in the preparation of graphene is mainly in the volumetric thermal layer method and the redox method. These two methods are simpler to operate and cost less than other preparation methods. Due to the cavitation in the liquid, the micro-jet, vibration and other phenomena are formed.

Features:

1. Reliable for heavy duty sonication processes

2. 24*7 hours continuous operation

3. Industrial grade

4. Colored touch display

5. PLC remote control

6. Automatic Frequency tuning

| Type | RPS-C30-10 | RPS-C30-50 | RPS-C30-300 |

| Input voltage | 380V/220V±10V 50Hz | ||

| Working frequency | 20KHz | ||

| Processing capacity | 10-30L | 50L | 300L |

Ultrasonic cavitation intensity

| 3.0-4.5(w/cm²) | ||

| Ultrasonic probe material | Titanium alloy | ||

| Reactor material | 304/316 stainless steel | ||

| Cooling method | Cold water cycle | ||

| Reactor type | U-shaped pipe | U-shaped pipe | Tank |

| Remote control | customized | ||

1) Intelligent control technology, stable ultrasonic energy output,stable work for 24 hours per day.

2) Automatic frequency tracking mode, ultrasonic transducer working frequency real-time tracking.

3) Multiple protection mechanisms to extend service life to more than 5 years.

4) Energy focus design, high output density, improve efficiency to 200 times in the suitable area.

5) Support static or cyclic working mode .

| Reactor Type | Stailess Steel U Shape Pipe | Horn Material | Titanium |

|---|---|---|---|

| Frequency | 20Khz | Capacity | 50L |

| Function | Graphene Dispersion,pigment Dispersion | Ultrasonic Cavitation Intensity | 3.0-4.5(w/cm²) |

| High Light | Titanium Horn Ultrasonic Dispersion Equipment,U Shaped Pipe Dispersion Equipment,20Khz Ultrasonic Liquid Processor | ||

Stainless Steel U Shaped Pipe Ultrasonic Graphene Dispersion Equipment 50L

Ultrasonic Graphene Dispersion Machine 50L Stainless Steel U Shaped Pipe Improve Efficiency Up To 200 Times

Product Descripiton:

The power of ultrasonic affects the efficiency of stripping graphite oxide into graphene oxide and the transverse size of graphene oxide. The higher the power is, the higher the efficiency is. Compared with the way of ultrasonic grinding, that is, direct action stripping, ultrasonic cleaning, that is, indirect action stripping, has less damage to the transverse size of graphite oxide, and can obtain graphene oxide with larger transverse size.

Graphene nanobelts were prepared from single-walled carbon nanotubes by gas-phase oxidation and ultrasonic pyrolysis. The morphology and structure of the prepared graphene nanobelts were analyzed by transmission electron microscopy (TEM), atomic force microscopy (AFM) and Raman spectroscopy (Raman). The results show that the width of graphene nanobelts prepared by Hannover instrument ultrasonic processor is narrow, the edge is smooth, and compared with the rigid single-walled carbon nanotubes, they have good flexibility. The thickness of about 2 nm also indicates the double-layer structure of graphene nanobelts. In the process of gas phase oxidation and ultrasonic pyrolysis, the ratio of D peak to G peak in Raman spectrum is always about 0.15, which indicates that no new defects are introduced in the whole preparation process.

Compared with other methods, the nanobelts prepared by RPS-SONIC ultrasonic processor have the advantages of high crystallinity, narrow width and smooth edge

Ultrasonic-assisted liquid phase exfoliation greatly improves the efficiency of graphene extraction.The application of ultrasonic equipment in the preparation of graphene is mainly in the volumetric thermal layer method and the redox method. These two methods are simpler to operate and cost less than other preparation methods. Due to the cavitation in the liquid, the micro-jet, vibration and other phenomena are formed.

Features:

1. Reliable for heavy duty sonication processes

2. 24*7 hours continuous operation

3. Industrial grade

4. Colored touch display

5. PLC remote control

6. Automatic Frequency tuning

| Type | RPS-C30-10 | RPS-C30-50 | RPS-C30-300 |

| Input voltage | 380V/220V±10V 50Hz | ||

| Working frequency | 20KHz | ||

| Processing capacity | 10-30L | 50L | 300L |

Ultrasonic cavitation intensity

| 3.0-4.5(w/cm²) | ||

| Ultrasonic probe material | Titanium alloy | ||

| Reactor material | 304/316 stainless steel | ||

| Cooling method | Cold water cycle | ||

| Reactor type | U-shaped pipe | U-shaped pipe | Tank |

| Remote control | customized | ||

1) Intelligent control technology, stable ultrasonic energy output,stable work for 24 hours per day.

2) Automatic frequency tracking mode, ultrasonic transducer working frequency real-time tracking.

3) Multiple protection mechanisms to extend service life to more than 5 years.

4) Energy focus design, high output density, improve efficiency to 200 times in the suitable area.

5) Support static or cyclic working mode .

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment