loading

| Availability: | |

|---|---|

| Quantity: | |

RPS-SONO20

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-C20-150 |

| Minimum Order Quantity | 1set |

| Packaging Details | carton box |

| Payment Terms | T/T |

| Horn Material | Titanium | Frequency | 20Khz |

|---|---|---|---|

| Power | 150W | Power Supply | Ultrasonic Digital Generator |

| Application | Beverage | Cooling | Water Cooling |

| High Light | Ultrasonic Beverage Defoaming Machine,150W Defoaming Machine,20Khz Defoaming Machine | ||

20Khz 150W Ultrasonic beverage defoaming machine with Titanum horn

Description:

The beverage defoaming system is designed to significantly reduce foam in the bottles/cans during the packaging operation creating a compressed and denser foam in the can or bottle. This enables the defoaming system to deliver significant productivity gains, filling line efficiency gains, reduced beverage waste, reduced contamination, energy & water saving, eliminate contamination on the package and quality improvements

Features:

| Frequency | 20Khz |

| Power | 150~500W |

| Horn Material | Titanium |

| Application | Beverage |

| Cooling | wate cooling |

| Control | With digital generator, it can connect with PLC remote control |

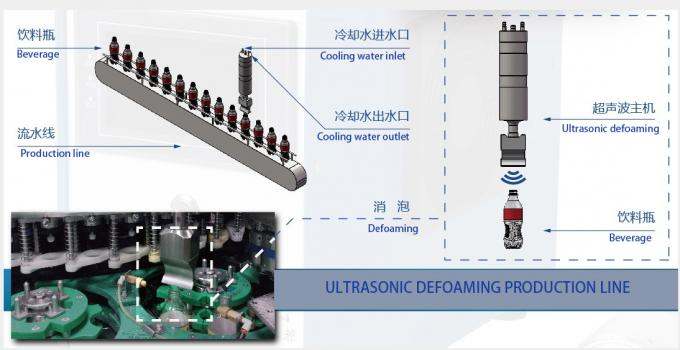

| Installation | No need to change the production line, just add the ultrasonic into the line |

| Max working speed | 1600bottles/minutes. |

| Defoaming for small area | bottle, can |

| Packing | carton box |

Key Benefits To The Beverage Packaging Line:

Increased filling line speed (5-60%): enhanced productivity gains or reduced operational days per week (savings on labour, energy, water, cleaning cycle/chemicals, waste treatment)

Reduced beverage/syrup losses by an average 1ml to 6ml per can or bottle: due to the foam compression effect, beverage losses are reduced and more beverage is kept in the bottle or can. Adjustment of the fill settings (volumetric filler) or tube length on filler valves (mechanical filler) allows for the beverage saving to be realized.

Reduced beverage waste (waste treatment cost): reduced waste treatment costs (beverage/water/chemicals)

Filling temperature increase: Potential to increase filling temperature by up to +6oC or more above the normal filling temperature (energy cost saving, eliminate condensation issues on bottle or can impacting down-stream processes in the plant (labeller, packing logistics)

Reduced bottle & can rejects due to underfill: reduced beverage losses, packaging material and reduction in waste treatment costs

Enhanced hygiene, reduced contamination on package and filler: due to the foam control effect, beverage stays in the bottle or can instead of contaminating the bottle and can filling line zone resulting in a cleaner line and potentially reduced cleaning cycles/CIP (energy, water, chemical saving, reduced down time on filler). Eliminating contamination and risk for microbial growth on the caps, threads and seal of the package.

Enhanced efficiency of filling lines where nitrogen dosing is applied: due to the defoaming effect in the bottle or package prior to capping, ,increased nitrogen dosing efficiency and greater nitrogen content in the capped bottle or package.

Applicable to carbonated, none carbonated beverages, juices, smoothies, energy drinks, tea & coffee drinks, flavoured water

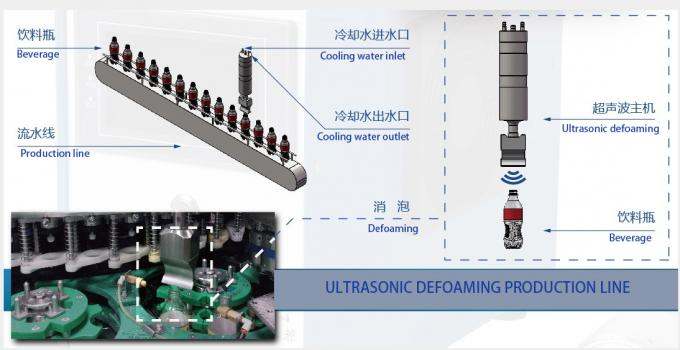

Installation of Production line

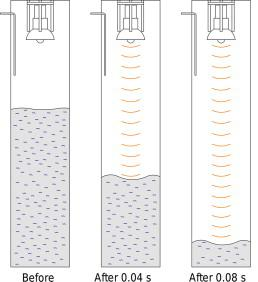

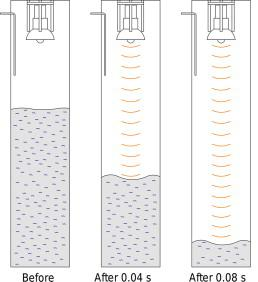

Defoaming:

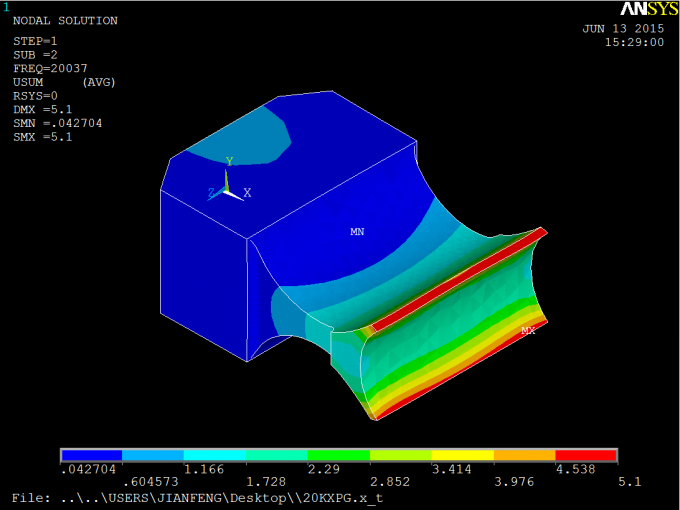

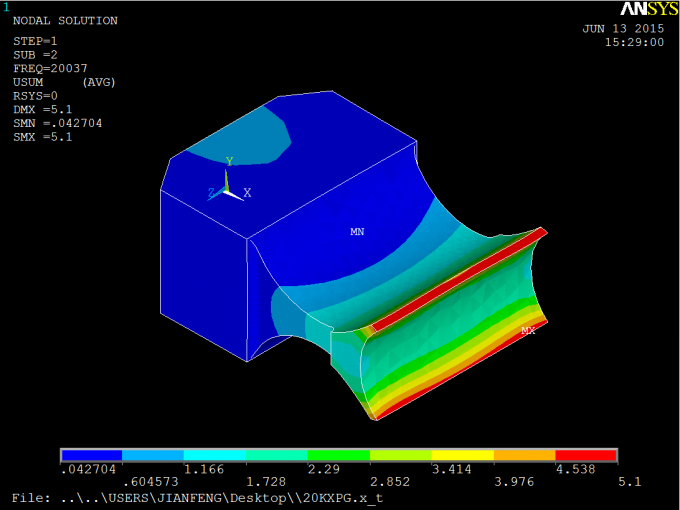

3.Horn drawing:

| Horn Material | Titanium | Frequency | 20Khz |

|---|---|---|---|

| Power | 150W | Power Supply | Ultrasonic Digital Generator |

| Application | Beverage | Cooling | Water Cooling |

| High Light | Ultrasonic Beverage Defoaming Machine,150W Defoaming Machine,20Khz Defoaming Machine | ||

20Khz 150W Ultrasonic beverage defoaming machine with Titanum horn

Description:

The beverage defoaming system is designed to significantly reduce foam in the bottles/cans during the packaging operation creating a compressed and denser foam in the can or bottle. This enables the defoaming system to deliver significant productivity gains, filling line efficiency gains, reduced beverage waste, reduced contamination, energy & water saving, eliminate contamination on the package and quality improvements

Features:

| Frequency | 20Khz |

| Power | 150~500W |

| Horn Material | Titanium |

| Application | Beverage |

| Cooling | wate cooling |

| Control | With digital generator, it can connect with PLC remote control |

| Installation | No need to change the production line, just add the ultrasonic into the line |

| Max working speed | 1600bottles/minutes. |

| Defoaming for small area | bottle, can |

| Packing | carton box |

Key Benefits To The Beverage Packaging Line:

Increased filling line speed (5-60%): enhanced productivity gains or reduced operational days per week (savings on labour, energy, water, cleaning cycle/chemicals, waste treatment)

Reduced beverage/syrup losses by an average 1ml to 6ml per can or bottle: due to the foam compression effect, beverage losses are reduced and more beverage is kept in the bottle or can. Adjustment of the fill settings (volumetric filler) or tube length on filler valves (mechanical filler) allows for the beverage saving to be realized.

Reduced beverage waste (waste treatment cost): reduced waste treatment costs (beverage/water/chemicals)

Filling temperature increase: Potential to increase filling temperature by up to +6oC or more above the normal filling temperature (energy cost saving, eliminate condensation issues on bottle or can impacting down-stream processes in the plant (labeller, packing logistics)

Reduced bottle & can rejects due to underfill: reduced beverage losses, packaging material and reduction in waste treatment costs

Enhanced hygiene, reduced contamination on package and filler: due to the foam control effect, beverage stays in the bottle or can instead of contaminating the bottle and can filling line zone resulting in a cleaner line and potentially reduced cleaning cycles/CIP (energy, water, chemical saving, reduced down time on filler). Eliminating contamination and risk for microbial growth on the caps, threads and seal of the package.

Enhanced efficiency of filling lines where nitrogen dosing is applied: due to the defoaming effect in the bottle or package prior to capping, ,increased nitrogen dosing efficiency and greater nitrogen content in the capped bottle or package.

Applicable to carbonated, none carbonated beverages, juices, smoothies, energy drinks, tea & coffee drinks, flavoured water

Installation of Production line

Defoaming:

3.Horn drawing:

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!