loading

| Availability: | |

|---|---|

| Quantity: | |

RPS-SONO20

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-S20 |

| Minimum Order Quantity | 1 |

| Price | Negotiation |

| Packaging Details | CARTON/WOODEN |

| Delivery Time | 3 work days after payment |

| Payment Terms | T/T, Western Union,PayPal |

| Supply Ability | 100sets |

| Power | 1000W-3000W | Frequency | 20KHZ |

|---|---|---|---|

| Application | Ultrasonic Liquid Processor Ballast/capacity Ultrasonic Liquid Processor | Material | Titanium Alloy |

| High Light | Ultrasonic High Pressure Homogeniser,20KHZ sonic homogenizer,1000W sonic homogenizer | ||

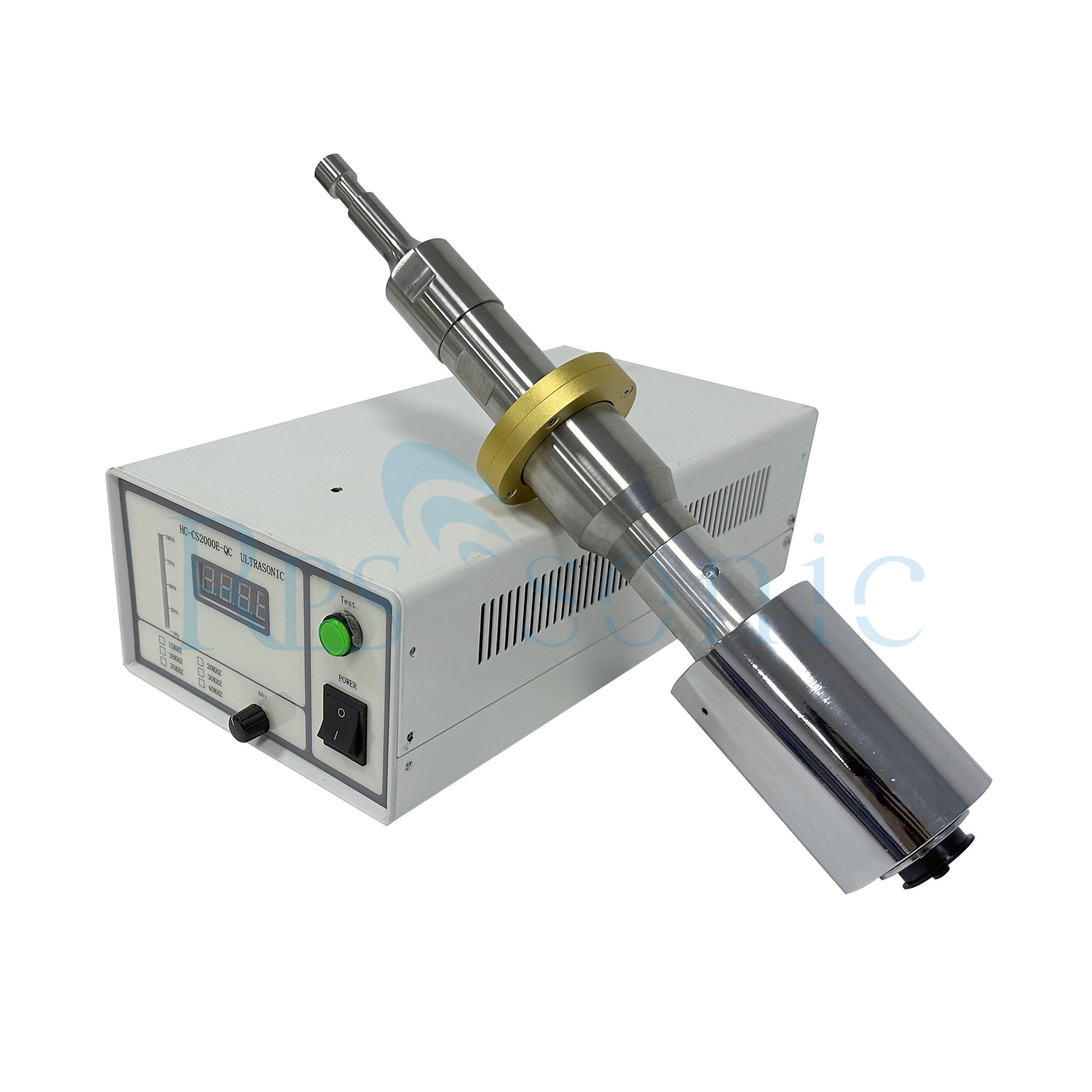

Ultrasonic High Pressure Homogeniser With Ultrasound Irradiation Permanent Controlled

Specifications:

| Model | RPSS20-1000 | RPSS20-1500 | RPSS20-2000 | RPSS20-3000 |

| Frequency | 20±1 KHz | 20±1 KHz | 20±1 KHz | 20±1 KHz |

| Power | 1000 W | 1500 W | 2000 W | 3000 W |

| Voltage | 220±10% V | 220±10% V | 220±10% V | 220±10% V |

| Temperature | 150 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | Normal | 35 MPa | 35 MPa | 35 MPa |

| Intensity of sound | >10 W/cm² | >30 W/cm² | >40 W/cm² | >60 W/cm² |

| Max Capacity | > 5 L/Min | > 15 L/Min | > 20 L/Min | > 30 L/Min |

| Material Of Tip Head | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Description:

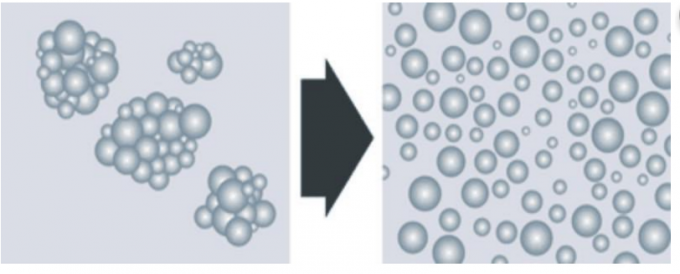

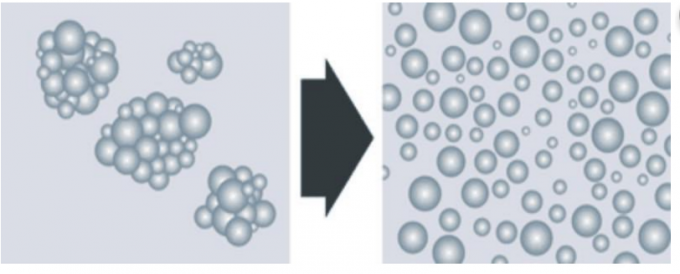

Ultrasound creates acoustic cavitation, which produces violently imploding vacuum bubbles, causing shock waves, microjets and strong shear forces as well as extreme local temperatures (~5,000 K) and pressures (~1,000 atm). These extreme conditions result in exceptionally efficient mixing, yielding nanoemulsions with very small droplet sizes and enormous contact areas between all components.

Applications:

Food processing

Sonochemistry

Reaction Acceleration – cavitation accelerates chemical and physical reactions.

Fine Particle

Dispersion – e.g. nanoparticle processing

Disruption and Cell Lysing – will break open biological tissues and

cells to extract enzymes and DNA, prepare vaccines.

This technology provides a method for

ultrasonically lysing cells and spores in a liquid flowing continuously or intermittently through a cylindrical reactor.

Homogenization – making uniform mixtures of liquids or liquid suspensions.

Emulsification – processing foods, pharmaceuticals, and cosmetics.

Dissolution – dissolving solids in solvents.

Degassing – removing gases from solutions without heat or vacuum.

Inline pipe cleaning, removes scale or build/up without disassembly.

Cylindrical 360° internally radiating chamber.

Internal or external liquid atomizing or powder making sonotrode.

Competitive Advantage:

Custom System Designs and Consulting:

Active Ultrasonics provides consulting services and custom reactor designs.

High amplitude probe flow cells

Unrestricted flow-through cylindrical systems

High Power Probe Sonicator

Custom sizes available for laboratory and high volume industrial applications.

| Power | 1000W-3000W | Frequency | 20KHZ |

|---|---|---|---|

| Application | Ultrasonic Liquid Processor Ballast/capacity Ultrasonic Liquid Processor | Material | Titanium Alloy |

| High Light | Ultrasonic High Pressure Homogeniser,20KHZ sonic homogenizer,1000W sonic homogenizer | ||

Ultrasonic High Pressure Homogeniser With Ultrasound Irradiation Permanent Controlled

Specifications:

| Model | RPSS20-1000 | RPSS20-1500 | RPSS20-2000 | RPSS20-3000 |

| Frequency | 20±1 KHz | 20±1 KHz | 20±1 KHz | 20±1 KHz |

| Power | 1000 W | 1500 W | 2000 W | 3000 W |

| Voltage | 220±10% V | 220±10% V | 220±10% V | 220±10% V |

| Temperature | 150 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | Normal | 35 MPa | 35 MPa | 35 MPa |

| Intensity of sound | >10 W/cm² | >30 W/cm² | >40 W/cm² | >60 W/cm² |

| Max Capacity | > 5 L/Min | > 15 L/Min | > 20 L/Min | > 30 L/Min |

| Material Of Tip Head | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Description:

Ultrasound creates acoustic cavitation, which produces violently imploding vacuum bubbles, causing shock waves, microjets and strong shear forces as well as extreme local temperatures (~5,000 K) and pressures (~1,000 atm). These extreme conditions result in exceptionally efficient mixing, yielding nanoemulsions with very small droplet sizes and enormous contact areas between all components.

Applications:

Food processing

Sonochemistry

Reaction Acceleration – cavitation accelerates chemical and physical reactions.

Fine Particle

Dispersion – e.g. nanoparticle processing

Disruption and Cell Lysing – will break open biological tissues and

cells to extract enzymes and DNA, prepare vaccines.

This technology provides a method for

ultrasonically lysing cells and spores in a liquid flowing continuously or intermittently through a cylindrical reactor.

Homogenization – making uniform mixtures of liquids or liquid suspensions.

Emulsification – processing foods, pharmaceuticals, and cosmetics.

Dissolution – dissolving solids in solvents.

Degassing – removing gases from solutions without heat or vacuum.

Inline pipe cleaning, removes scale or build/up without disassembly.

Cylindrical 360° internally radiating chamber.

Internal or external liquid atomizing or powder making sonotrode.

Competitive Advantage:

Custom System Designs and Consulting:

Active Ultrasonics provides consulting services and custom reactor designs.

High amplitude probe flow cells

Unrestricted flow-through cylindrical systems

High Power Probe Sonicator

Custom sizes available for laboratory and high volume industrial applications.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment