loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-SONO20-2000 |

| Minimum Order Quantity | 1set |

| Price | $3800/SET |

| Packaging Details | carton box |

| Supply Ability | 200SETS |

| Horn Material | Titanium | Frequency | 20Khz |

|---|---|---|---|

| Power | 2000W | Power Supply | Ultrasonic Digital Generator |

| Voltage | 220/110V | Temperature | 300 ℃ |

| Pressure | 35 MPa | ||

| High Light | Nanoparticles Ultrasonic Dispersion Machine,Titanium Horn Ultrasonic Dispersion Machine,2000 Watt Ultrasonic Dispersion Equipment | ||

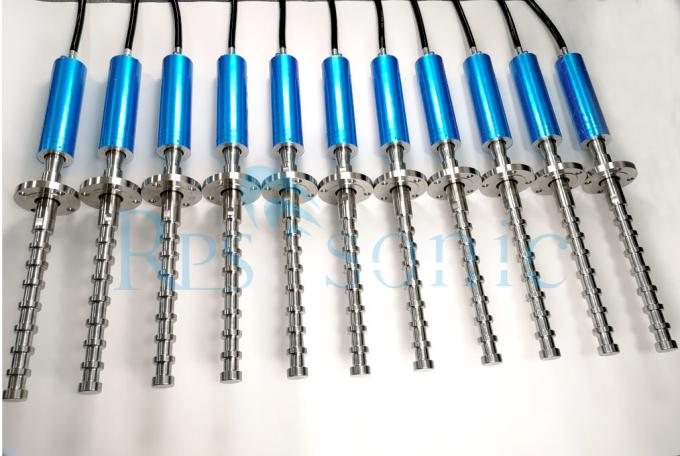

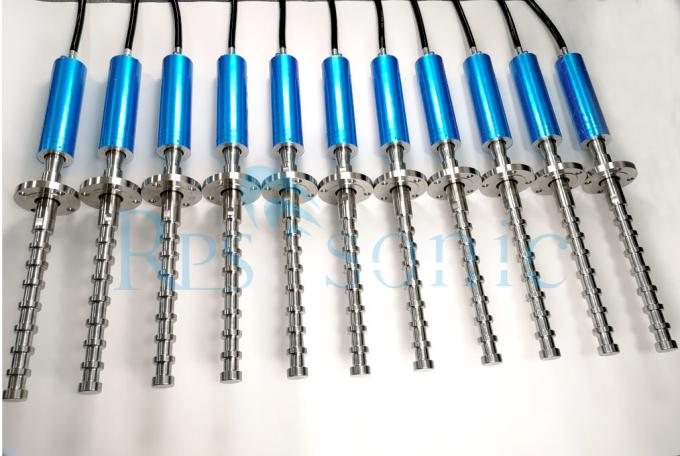

20Khz 2000W Ultrasonic Nano particles dispersion machine with Titanium horn

What's the theory of ultrasonic sonochemistry?

The essence of the sonochemical effect is the cavitation effect, including the appearance of the gas nucleus, the growth of the microbubbles and the bursting of the microbubbles. Under the action of ultrasound, the fluid produces a sharp motion. Due to the change of sound pressure, the solvent is compressed and sparse. In the sparse phase region of the sound wave, the gas bubble expands and is filled with the surrounding liquid vapor or gas. In the compressed phase region, the air pockets quickly collapse and rupture, producing a large number of microbubbles, which in turn can serve as new gas cores. It is currently believed that the main reason for the influence of ultrasound on chemical reactions is that these microbubbles can generate strong shock waves when they grow up and suddenly rupture. It is estimated that when the microbubble bursts, it can generate pressures up to MPa in the local space, and the center temperature can reach 3000-5000K. The interpretation of the action of the ultrasonic field has not yet entered the molecular level, but stays in the machinery of the molecular group. The level of action mechanism. For example, the cavitation and cleansing effect on the solid surface; the emulsification of the immiscible liquid; the effect of the high temperature and high pressure caused by the shock wave in the micro space on mass transfer and energy transfer when the microbubble bursts.

Parameter

| Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

| Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

| Power | 1000 W | 2000 W | 3000 W | 3000 W |

| Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

| Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Intensity of sound | 20 W/cm² | 40 W/cm² | 60 W/cm² | 60 W/cm² |

| Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

| Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Application:

Ultrasonic sonochemistry equipment are powerful,efficient and reliable.It is widely used in industry liquid process,such as:

1. Herb extraction.

2. Dispersing and milling of pigments in paint or ink.

3. Manufacturing of bio-diesel.

4. Homogenize food or beverage during the mixing.

5. Emulsify the shampoo or other chemical process

6. Graphene making

Other liquid mixing process

| Horn Material | Titanium | Frequency | 20Khz |

|---|---|---|---|

| Power | 2000W | Power Supply | Ultrasonic Digital Generator |

| Voltage | 220/110V | Temperature | 300 ℃ |

| Pressure | 35 MPa | ||

| High Light | Nanoparticles Ultrasonic Dispersion Machine,Titanium Horn Ultrasonic Dispersion Machine,2000 Watt Ultrasonic Dispersion Equipment | ||

20Khz 2000W Ultrasonic Nano particles dispersion machine with Titanium horn

What's the theory of ultrasonic sonochemistry?

The essence of the sonochemical effect is the cavitation effect, including the appearance of the gas nucleus, the growth of the microbubbles and the bursting of the microbubbles. Under the action of ultrasound, the fluid produces a sharp motion. Due to the change of sound pressure, the solvent is compressed and sparse. In the sparse phase region of the sound wave, the gas bubble expands and is filled with the surrounding liquid vapor or gas. In the compressed phase region, the air pockets quickly collapse and rupture, producing a large number of microbubbles, which in turn can serve as new gas cores. It is currently believed that the main reason for the influence of ultrasound on chemical reactions is that these microbubbles can generate strong shock waves when they grow up and suddenly rupture. It is estimated that when the microbubble bursts, it can generate pressures up to MPa in the local space, and the center temperature can reach 3000-5000K. The interpretation of the action of the ultrasonic field has not yet entered the molecular level, but stays in the machinery of the molecular group. The level of action mechanism. For example, the cavitation and cleansing effect on the solid surface; the emulsification of the immiscible liquid; the effect of the high temperature and high pressure caused by the shock wave in the micro space on mass transfer and energy transfer when the microbubble bursts.

Parameter

| Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

| Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

| Power | 1000 W | 2000 W | 3000 W | 3000 W |

| Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

| Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Intensity of sound | 20 W/cm² | 40 W/cm² | 60 W/cm² | 60 W/cm² |

| Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

| Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Application:

Ultrasonic sonochemistry equipment are powerful,efficient and reliable.It is widely used in industry liquid process,such as:

1. Herb extraction.

2. Dispersing and milling of pigments in paint or ink.

3. Manufacturing of bio-diesel.

4. Homogenize food or beverage during the mixing.

5. Emulsify the shampoo or other chemical process

6. Graphene making

Other liquid mixing process

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!