loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-W35 |

| Minimum Order Quantity | 1set |

| Price | $1800/SET |

| Packaging Details | carton box |

| Payment Terms | T/T |

| Material | Rapid Steel,Titanium | Frequency | 35Khz |

|---|---|---|---|

| Power | 800W,1000W | Generator | Digital Ultrasonic Generator |

| Horn Pattern | Can Be Customized | ||

| High Light | Titanium Material Ultrasonic Welding Gun,1000W Ultrasonic Welding Gun | ||

35Khz 1000W Easy Operation Handheld Ultrasonic Welding Gun For Automotive Industry

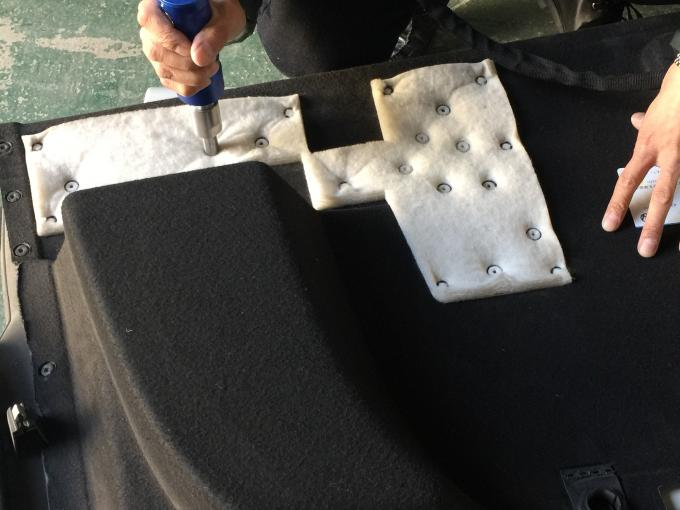

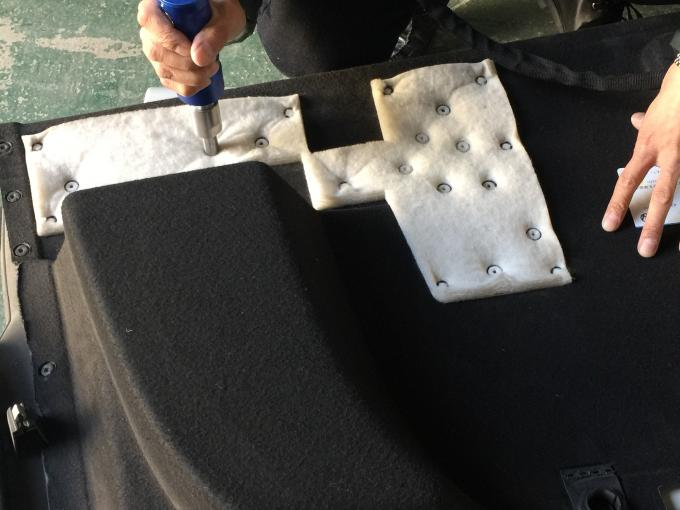

Ultrasonic hand welder offers a low cost solution for parts where automation is not viable or production volumes are low. Application areas include spot-welding, staking of components, access to difficult weld areas and second operations/re-work.

Ultrasonic welding, for thermoplastic injection moulded components, is a process that uses mechanical vibrations above the audible range. The vibrations, produced by a welding sonotrode or horn, as it is generally known, are used to soften or melt the thermoplastic material at the joint line. The components to be joined are held together under pressure and subjected to vibrations, usually at a frequency of 20 to 40kHz.

The ability to weld a component successfully is governed by the design of the equipment, the mechanical properties of the material to be welded and the design of the components and joint. Ultrasonic welding times are short (typically less than one second), which makes the process ideal for mass production. The process is widely accepted in many applications ranging from automotive light clusters to consumer electronics products, such as mobile telephone casings.

The design and lightness of the manual pistol handgrip have been carefully delineated in order to assure a practical and comfortable handling when in use.

Ultrasonic welding guns are used to weld thermoplastic, where areas of welding are hard to reach the parts are too bigger to weld.

Application: welding, joint, embedding, spot-welding, cutting

Material: Acrylonitrile -butadiene-styrene (ABS), polystyrene(PS), SNA, non-woven fabrics, nylon, polyester, paper, leather, etc.

| Model Number | RPS-W35 |

| Environmental Condition | -10℃~+40℃,

Damp heat lower than 70% |

| Dimensions | Length 41cm, Width 12cm, Height 11.9cm |

| Transducer Adaptor | 35kHz |

| Power | 800W/1000W |

| Material | Case: aluminum alloy ; Panel: 304 stainless steel;

Heating panel: 6061 aluminum alloy |

| Power Supply | 220VAC,50/60HZ |

| Standard Accessory | Ultrasonic generator, 35K transducer hand gun, power cable |

| Optional Accessory | Shockproof suitcase, Titanium Alloy flat-die, cooling solenoid valve |

Automotive industry

Prototype/trials work

Conveyor belt repair

Re-work for automation

Fabric repairs and joining

Blister packs

Vac forming- component retaining

Equipment is mobile

Our hand-held thermoplastic welding tools meet two needs: welding of hard-to-reach areas and tamper-proof sealing of packaging.

In practically no time your production teams will be producing clean welds with our ultrasonic gun and pencil.

These tools are designed for ease of use, adaptability and flexibility to ensure clean and strong welds.

We have the solution to all your assembly needs.

We also have metal housing welding pencil, for welsing machine assembly.

| Material | Rapid Steel,Titanium | Frequency | 35Khz |

|---|---|---|---|

| Power | 800W,1000W | Generator | Digital Ultrasonic Generator |

| Horn Pattern | Can Be Customized | ||

| High Light | Titanium Material Ultrasonic Welding Gun,1000W Ultrasonic Welding Gun | ||

35Khz 1000W Easy Operation Handheld Ultrasonic Welding Gun For Automotive Industry

Ultrasonic hand welder offers a low cost solution for parts where automation is not viable or production volumes are low. Application areas include spot-welding, staking of components, access to difficult weld areas and second operations/re-work.

Ultrasonic welding, for thermoplastic injection moulded components, is a process that uses mechanical vibrations above the audible range. The vibrations, produced by a welding sonotrode or horn, as it is generally known, are used to soften or melt the thermoplastic material at the joint line. The components to be joined are held together under pressure and subjected to vibrations, usually at a frequency of 20 to 40kHz.

The ability to weld a component successfully is governed by the design of the equipment, the mechanical properties of the material to be welded and the design of the components and joint. Ultrasonic welding times are short (typically less than one second), which makes the process ideal for mass production. The process is widely accepted in many applications ranging from automotive light clusters to consumer electronics products, such as mobile telephone casings.

The design and lightness of the manual pistol handgrip have been carefully delineated in order to assure a practical and comfortable handling when in use.

Ultrasonic welding guns are used to weld thermoplastic, where areas of welding are hard to reach the parts are too bigger to weld.

Application: welding, joint, embedding, spot-welding, cutting

Material: Acrylonitrile -butadiene-styrene (ABS), polystyrene(PS), SNA, non-woven fabrics, nylon, polyester, paper, leather, etc.

| Model Number | RPS-W35 |

| Environmental Condition | -10℃~+40℃,

Damp heat lower than 70% |

| Dimensions | Length 41cm, Width 12cm, Height 11.9cm |

| Transducer Adaptor | 35kHz |

| Power | 800W/1000W |

| Material | Case: aluminum alloy ; Panel: 304 stainless steel;

Heating panel: 6061 aluminum alloy |

| Power Supply | 220VAC,50/60HZ |

| Standard Accessory | Ultrasonic generator, 35K transducer hand gun, power cable |

| Optional Accessory | Shockproof suitcase, Titanium Alloy flat-die, cooling solenoid valve |

Automotive industry

Prototype/trials work

Conveyor belt repair

Re-work for automation

Fabric repairs and joining

Blister packs

Vac forming- component retaining

Equipment is mobile

Our hand-held thermoplastic welding tools meet two needs: welding of hard-to-reach areas and tamper-proof sealing of packaging.

In practically no time your production teams will be producing clean welds with our ultrasonic gun and pencil.

These tools are designed for ease of use, adaptability and flexibility to ensure clean and strong welds.

We have the solution to all your assembly needs.

We also have metal housing welding pencil, for welsing machine assembly.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!