loading

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-SW28 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 28Khz | Power | 800w |

|---|---|---|---|

| Horn Material | Titanium | Horn Size | Customized |

| Generator | Digital | Weight | 6kg |

| Warranty | One Year | Package | Carton |

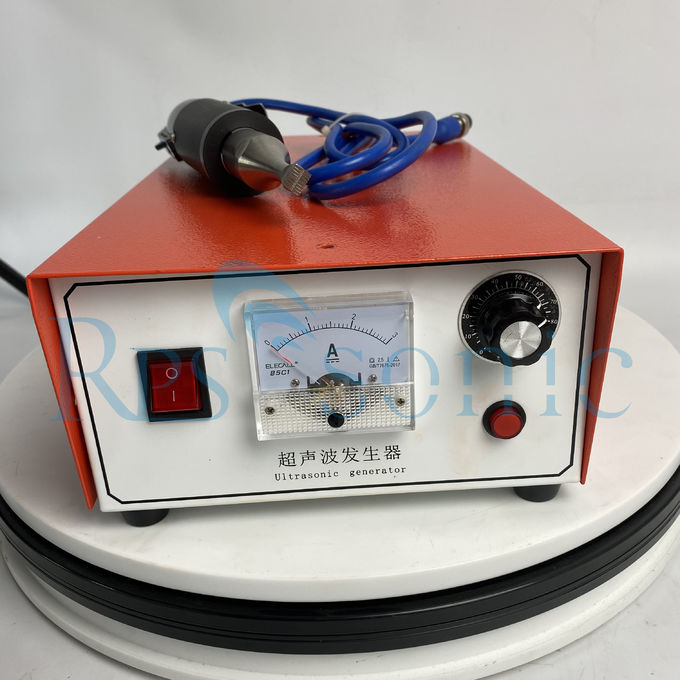

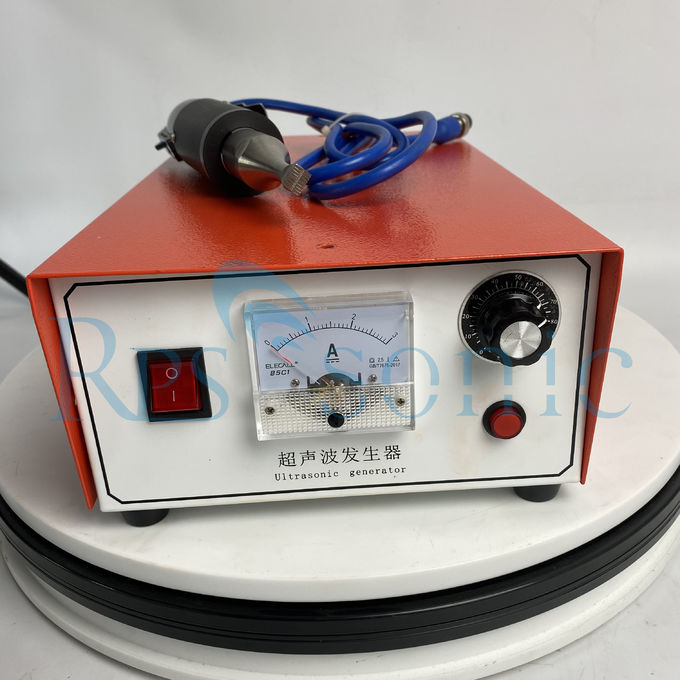

Handheld 28khz 800w Ultrasonic Spot Welding machine For ribbon welding

Paremeter:

| Item | 20 | 28 | 35 | 40 |

| Frequency | 20Khz | 28khz | 35khz | 40khz |

| Power | 800w | 600w | 500w | 300w |

| Horn tip diameter | 12mm | 10mm | 8mm | 8mm |

| Horn material | Aluminum alloy&Steel & Titanium alloy | |||

| Generator | Digital generator | |||

What are the signs of high-quality solder joints?

The most commonly used method for testing specimens is the tear-off method. One piece of the tear-off specimen has a round hole and the other piece has a round boss. Thick plates or quenched materials sometimes cannot tear the round holes and bosses, but the diameter of the nugget can be judged by the cut fracture. When necessary, low-magnification measurement, tensile test and X-ray inspection are also required to determine the welding rate, shear strength, shrinkage cavity, cracks, etc.

How are weld nuggets of different thicknesses and different materials formed?

When spot welding of unequal thickness or different materials is performed, the solder joint will be asymmetrical to its interface, but will shift to the side with poor thickness or conductivity and thermal conductivity. The result of the deviation will make thin parts or good conductivity and thermal conductivity. The penetration rate of the workpiece is reduced, and the strength of the solder joint is reduced. The offset of the solder joint is caused by the difference in melting point and quality of the two workpieces. When the thickness is not equal, the resistance on one side of the thickness is large and the interface is far away from the welding head, so more heat is generated but less heat dissipation, which causes the solder joints to be biased toward thick parts; when the materials are different, materials with poor thermal conductivity are easy to generate heat but difficult to dissipate, so The solder joints are also biased towards this material

Application fields of handheld ultrasonic welding machine:

1. Automobile: (Traffic) Ultrasonic cm01 can be controlled by computer programs to weld large and irregular workpieces such as bumpers, front and rear doors, lamps, brake lights, etc. With the development of high-grade roads, more and more reflectors are welded by ultrasonic.

2. Home appliances: After proper adjustment, it can be used for: portable fluorescent lampshade, steam ironing door, TV shell, recording, transparent panel of sound machine, power rectifier, screw fixing seat of TV shell, mosquito-reducing lamp shell, washing machine dehydration tank, etc. Sealed, strong and beautiful household appliances.

3. Packing: The sealing of the hose, the connection of the special packing belt.

4. Toy industry: Because of the use of ultrasonic technology to make products clean, efficient and firm, it eliminates the use of screws, adhesives, glues or other auxiliary products, reduces production costs, and greatly enhances the competitiveness of enterprises in the market.

5. Electronics: The use of automation program design enables users to achieve large-scale production, while ensuring product quality requirements.

| Frequency | 28Khz | Power | 800w |

|---|---|---|---|

| Horn Material | Titanium | Horn Size | Customized |

| Generator | Digital | Weight | 6kg |

| Warranty | One Year | Package | Carton |

Handheld 28khz 800w Ultrasonic Spot Welding machine For ribbon welding

Paremeter:

| Item | 20 | 28 | 35 | 40 |

| Frequency | 20Khz | 28khz | 35khz | 40khz |

| Power | 800w | 600w | 500w | 300w |

| Horn tip diameter | 12mm | 10mm | 8mm | 8mm |

| Horn material | Aluminum alloy&Steel & Titanium alloy | |||

| Generator | Digital generator | |||

What are the signs of high-quality solder joints?

The most commonly used method for testing specimens is the tear-off method. One piece of the tear-off specimen has a round hole and the other piece has a round boss. Thick plates or quenched materials sometimes cannot tear the round holes and bosses, but the diameter of the nugget can be judged by the cut fracture. When necessary, low-magnification measurement, tensile test and X-ray inspection are also required to determine the welding rate, shear strength, shrinkage cavity, cracks, etc.

How are weld nuggets of different thicknesses and different materials formed?

When spot welding of unequal thickness or different materials is performed, the solder joint will be asymmetrical to its interface, but will shift to the side with poor thickness or conductivity and thermal conductivity. The result of the deviation will make thin parts or good conductivity and thermal conductivity. The penetration rate of the workpiece is reduced, and the strength of the solder joint is reduced. The offset of the solder joint is caused by the difference in melting point and quality of the two workpieces. When the thickness is not equal, the resistance on one side of the thickness is large and the interface is far away from the welding head, so more heat is generated but less heat dissipation, which causes the solder joints to be biased toward thick parts; when the materials are different, materials with poor thermal conductivity are easy to generate heat but difficult to dissipate, so The solder joints are also biased towards this material

Application fields of handheld ultrasonic welding machine:

1. Automobile: (Traffic) Ultrasonic cm01 can be controlled by computer programs to weld large and irregular workpieces such as bumpers, front and rear doors, lamps, brake lights, etc. With the development of high-grade roads, more and more reflectors are welded by ultrasonic.

2. Home appliances: After proper adjustment, it can be used for: portable fluorescent lampshade, steam ironing door, TV shell, recording, transparent panel of sound machine, power rectifier, screw fixing seat of TV shell, mosquito-reducing lamp shell, washing machine dehydration tank, etc. Sealed, strong and beautiful household appliances.

3. Packing: The sealing of the hose, the connection of the special packing belt.

4. Toy industry: Because of the use of ultrasonic technology to make products clean, efficient and firm, it eliminates the use of screws, adhesives, glues or other auxiliary products, reduces production costs, and greatly enhances the competitiveness of enterprises in the market.

5. Electronics: The use of automation program design enables users to achieve large-scale production, while ensuring product quality requirements.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!