loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-MW20 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 2000~6000w |

|---|---|---|---|

| Horn Material | Titanium | Horn Size | Customized |

| Generator | Digital | Weight | 55kg |

| Warranty | One Year | Package | Wooden |

| High Light | Ultrasonic Welding Machine 20Khz,Touch Screen Ultrasonic Welding Machine,Ultrasonic Welding Equipment 6000 Watt | ||

20Khz 6000w High Power Ultrasonic Welding Machine With Touch Screen

20Khz 6000w Ultrasonic metal welding machine for metal welding

Parameter

| Power | 2000---6000W | Frequency | 20KHZ |

| Power supply | 220V | Gas source | 0.5kg |

| Way to control | Touch screen | Welding area range | 1mm---5mm |

| Welding mode | Automic | Welding time area | 0.01sec-999sec |

| Bracket size | 700LX600WX300H MM | Quality control | 1year |

| Generator size | 400LX280W220H MM | Whole weight | 60kg |

| Main component information | Transducer, mold, generator. | ||

Description

Ultrasonic metal welding uses high-frequency vibration waves to be transmitted to two metal surfaces to be welded. Under pressure, the two metal surfaces are rubbed against each other to form a fusion between molecular layers. Its advantages are rapid, energy-saving, and fusion. High strength, good electrical conductivity, no sparks, close to cold processing; the disadvantage is that the welded metal parts should not be too thick (generally less than or equal to 5mm), the solder joints should not be too large, and they need to be pressurized. Ultrasonic metal welding was discovered by accident in the 1830s. At that time, during the current spot welding electrode plus ultrasonic vibration test, it was found that it could be welded without current, so the ultrasonic metal cold welding technology was developed. Although ultrasonic welding was discovered earlier, its mechanism of action is still not very clear so far. It is similar to friction welding, but there are differences. Ultrasonic welding has a short time and the temperature is lower than recrystallization; it is also different from pressure welding because the static pressure applied is much smaller than that of pressure welding. It is generally believed that in the initial stage of the ultrasonic welding process, the tangential vibration removes the oxides on the metal surface, and the protruding part of the rough surface produces repeated micro-welding and destruction, which increases the contact area and increases the temperature of the welding zone. High, plastic deformation occurs at the interface of the weldment. In this way, under the action of contact pressure, when they approach each other to the distance at which atomic gravity can act, a solder joint is formed. The welding time is too long, or the ultrasonic amplitude is too large, which will reduce the welding strength or even destroy it.

Advantages of ultrasonic welding

※Good electrical and thermal conductivity after welding, extremely low resistivity (almost no change in the internal resistance of the material) ※The welding material does not need to reach the melting point to achieve the welding effect ↓ Not fragile metal characteristics

※The soldering time is short, no flux or gas solder is needed

※Low requirements on the surface of the welded metal, both oxidation and plating can be welded. ※Easy to realize the welding between dissimilar metals and realize automatic control. ※The welding is non-sparking, environmentally friendly, safe and efficient

Conventional and applicable products for ultrasonic metal welding

Power battery, 3C lithium battery multilayer positive and negative welding

Soft and hard connection welding of battery pack module. Combination welding of dissimilar materials such as copper sheet and aluminum sheet

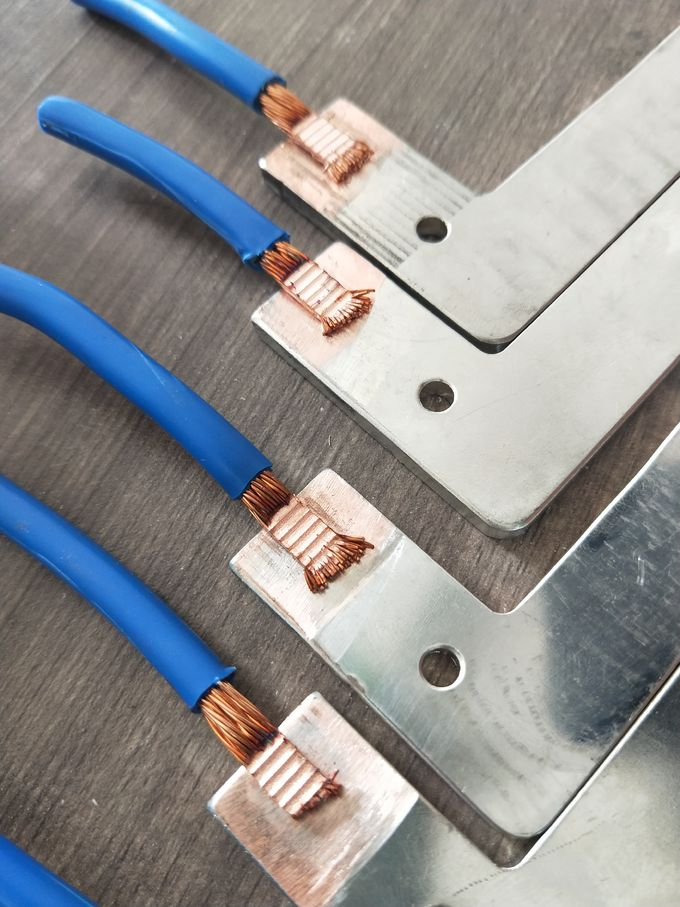

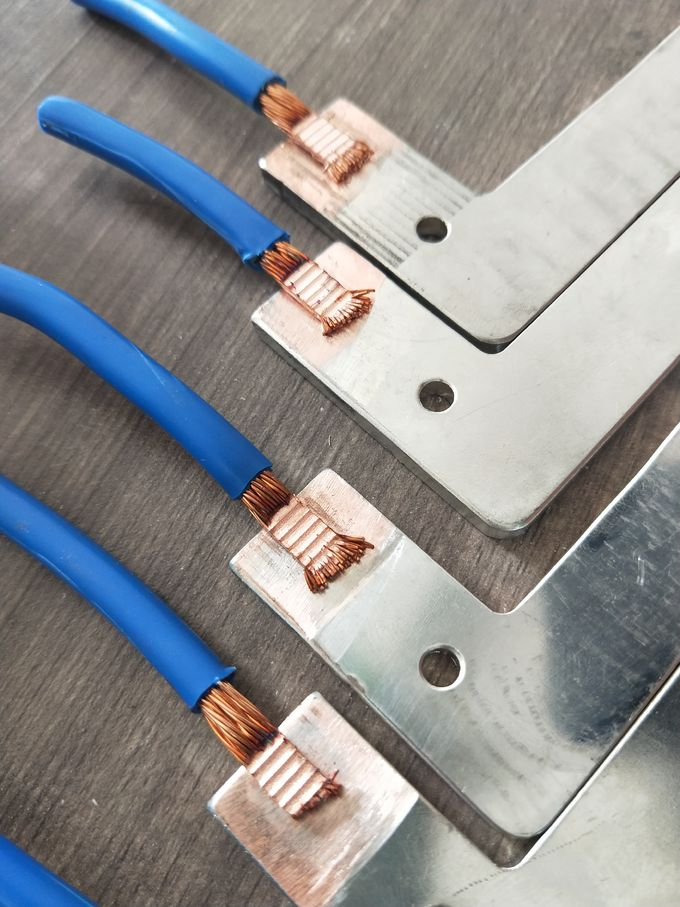

Automobile wiring harness, wiring harness terminal, multiple wires are mutually welded into a wire knot, copper wire wire conversion welding

Wire and various electronic components, connectors, terminals, contacts are welded

Fusion welding of dissimilar metal sheets such as copper-aluminum, copper-nickel, aluminum-nickel, copper-aluminum-nickel, titanium-aluminum, etc.

Copper pipes in refrigerators, air conditioners and other industries are sealed, and the copper and aluminum can be sealed and cut for water and air tightness.

Welding of high-current contacts such as non-fuse switches, electromagnetic switches, etc. 5828 nickel mesh, aluminum mesh, nickel foil, copper aluminum foil, solar heat absorption plate welding

| Frequency | 20Khz | Power | 2000~6000w |

|---|---|---|---|

| Horn Material | Titanium | Horn Size | Customized |

| Generator | Digital | Weight | 55kg |

| Warranty | One Year | Package | Wooden |

| High Light | Ultrasonic Welding Machine 20Khz,Touch Screen Ultrasonic Welding Machine,Ultrasonic Welding Equipment 6000 Watt | ||

20Khz 6000w High Power Ultrasonic Welding Machine With Touch Screen

20Khz 6000w Ultrasonic metal welding machine for metal welding

Parameter

| Power | 2000---6000W | Frequency | 20KHZ |

| Power supply | 220V | Gas source | 0.5kg |

| Way to control | Touch screen | Welding area range | 1mm---5mm |

| Welding mode | Automic | Welding time area | 0.01sec-999sec |

| Bracket size | 700LX600WX300H MM | Quality control | 1year |

| Generator size | 400LX280W220H MM | Whole weight | 60kg |

| Main component information | Transducer, mold, generator. | ||

Description

Ultrasonic metal welding uses high-frequency vibration waves to be transmitted to two metal surfaces to be welded. Under pressure, the two metal surfaces are rubbed against each other to form a fusion between molecular layers. Its advantages are rapid, energy-saving, and fusion. High strength, good electrical conductivity, no sparks, close to cold processing; the disadvantage is that the welded metal parts should not be too thick (generally less than or equal to 5mm), the solder joints should not be too large, and they need to be pressurized. Ultrasonic metal welding was discovered by accident in the 1830s. At that time, during the current spot welding electrode plus ultrasonic vibration test, it was found that it could be welded without current, so the ultrasonic metal cold welding technology was developed. Although ultrasonic welding was discovered earlier, its mechanism of action is still not very clear so far. It is similar to friction welding, but there are differences. Ultrasonic welding has a short time and the temperature is lower than recrystallization; it is also different from pressure welding because the static pressure applied is much smaller than that of pressure welding. It is generally believed that in the initial stage of the ultrasonic welding process, the tangential vibration removes the oxides on the metal surface, and the protruding part of the rough surface produces repeated micro-welding and destruction, which increases the contact area and increases the temperature of the welding zone. High, plastic deformation occurs at the interface of the weldment. In this way, under the action of contact pressure, when they approach each other to the distance at which atomic gravity can act, a solder joint is formed. The welding time is too long, or the ultrasonic amplitude is too large, which will reduce the welding strength or even destroy it.

Advantages of ultrasonic welding

※Good electrical and thermal conductivity after welding, extremely low resistivity (almost no change in the internal resistance of the material) ※The welding material does not need to reach the melting point to achieve the welding effect ↓ Not fragile metal characteristics

※The soldering time is short, no flux or gas solder is needed

※Low requirements on the surface of the welded metal, both oxidation and plating can be welded. ※Easy to realize the welding between dissimilar metals and realize automatic control. ※The welding is non-sparking, environmentally friendly, safe and efficient

Conventional and applicable products for ultrasonic metal welding

Power battery, 3C lithium battery multilayer positive and negative welding

Soft and hard connection welding of battery pack module. Combination welding of dissimilar materials such as copper sheet and aluminum sheet

Automobile wiring harness, wiring harness terminal, multiple wires are mutually welded into a wire knot, copper wire wire conversion welding

Wire and various electronic components, connectors, terminals, contacts are welded

Fusion welding of dissimilar metal sheets such as copper-aluminum, copper-nickel, aluminum-nickel, copper-aluminum-nickel, titanium-aluminum, etc.

Copper pipes in refrigerators, air conditioners and other industries are sealed, and the copper and aluminum can be sealed and cut for water and air tightness.

Welding of high-current contacts such as non-fuse switches, electromagnetic switches, etc. 5828 nickel mesh, aluminum mesh, nickel foil, copper aluminum foil, solar heat absorption plate welding

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!