loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-LP20 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 1000-3000w |

|---|---|---|---|

| Horn Material | Titanium | Horn Size | Customized |

| Generator | Digital | Weight | 23kg |

| Package | Wooden | Warranty | One Year |

| High Light | PLC Control Ultrasonic Dispersion Equipment,Nano Ultrasonic Dispersion Equipment,Titanium Ultrasonic Dispersion Equipment | ||

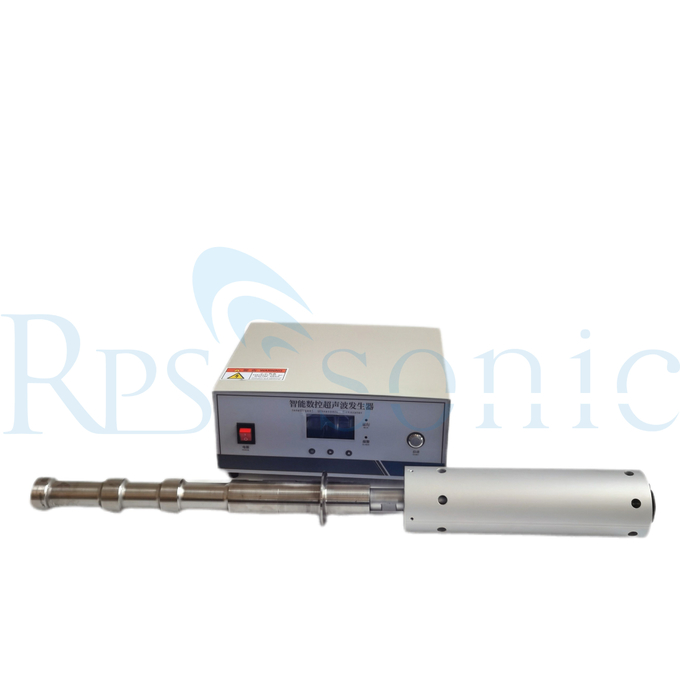

High Power Nano Material Ultrasonic Dispersion Equipment 20Khz 1500w Ultrasonic Breaker

20Khz high quality Ultrasonic nano material dispersion equipment

Parameter

| Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

| Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

| Power | 1000 W | 2000 W | 3000 W | 3000 W |

| Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

| Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Intensity of sound | 20 W/cm² | 40 W/cm² | 60 W/cm² | 60 W/cm² |

| Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

| Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Description

Ultrasonic nano-material dispersion system uses the principle of ultrasound to quickly and uniformly disperse the agglomeration of nano-materials physically and wetly, thus thoroughly breaking through this technical difficulty. Realize large-scale production equipment to meet customer's multi-type and different levels of industrial production needs. According to the difference of different media, concentration and process, the distribution and intensity of ultrasonic cavitation field (sound field) are not the same. Researchers can use ultrasonic equipment to control and calibrate the cavitation effect in the liquid, so as to solve the problem of industrial production. problem.

In recent years, nanomaterial B has been widely used in various industries to optimize the performance of materials. For example, adding graphene paint to the battery can greatly extend the service life of the battery, while adding silicon oxide to the glass can increase the transparency and robustness of the glass.

The core content of nanotechnology is how to solve the problem of nanoparticle agglomeration. Because nanoparticle itself is very easy to agglomerate, it is very difficult to obtain a single dispersed nanoparticle. How to uniformly disperse nanoparticles into the matrix is the key technology of nanotechnology.

In order to obtain excellent nanoparticles, an effective method is required. Ultrasonic cavitation immediately forms countless high-pressure and low-pressure areas in the solution. These high-pressure and low-pressure areas continuously collide with each other to generate strong shear force, depolymerize and reduce the size of the material. Ultrasonic waves used in the dispersion of nano-materials generally require relatively large sound pressure and ultrasonic amplitude. Therefore, horn type, that is, probe type, is more commonly used at present.

Recommendations

1. If you are new to nano materials and want to understand the effect of ultrasonic dispersion, you can use 1000W / 1500W laboratory materials.

2. If you are a small and medium enterprise that handles less than 5 tons of liquid per day, you can choose to add an ultrasonic probe to the reaction tank. You can use a 3000W probe.

3. If it is a large enterprise that needs to process dozens of tons or even hundreds of tons of liquid every day, an external ultrasonic circulation system is required. Multiple sets of ultrasonic equipment can process the circulation at the same time to achieve the desired effect.

Features

1. Unique focusing tool head design, higher energy concentration, larger amplitude and better homogenization effect.

2 The ultrasonic treatment process can be controlled, so the terminal state of the dispersion is also controllable, thereby greatly reducing the damage to the solution components.

3 It can disperse materials to nanometer level, and can handle high-viscosity solutions. The equipment can be equipped with PLC control, which makes the operation easier and the effect is more precise

| Frequency | 20Khz | Power | 1000-3000w |

|---|---|---|---|

| Horn Material | Titanium | Horn Size | Customized |

| Generator | Digital | Weight | 23kg |

| Package | Wooden | Warranty | One Year |

| High Light | PLC Control Ultrasonic Dispersion Equipment,Nano Ultrasonic Dispersion Equipment,Titanium Ultrasonic Dispersion Equipment | ||

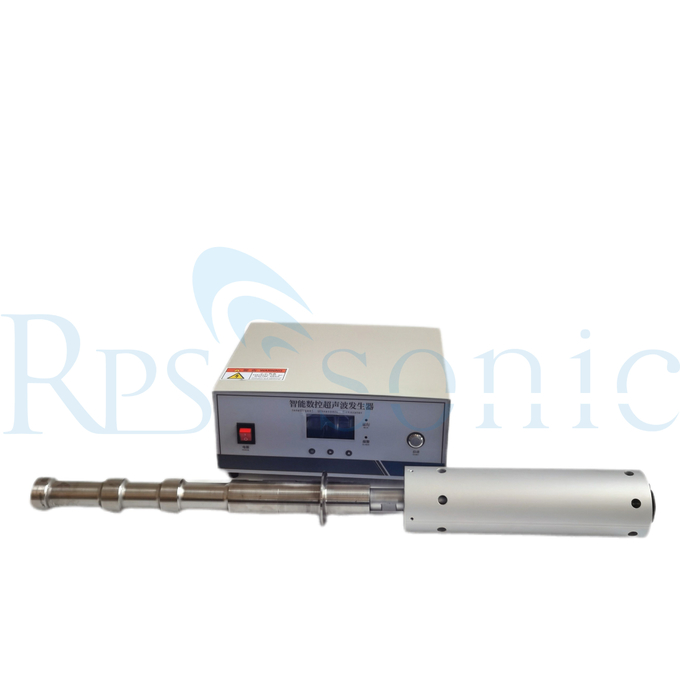

High Power Nano Material Ultrasonic Dispersion Equipment 20Khz 1500w Ultrasonic Breaker

20Khz high quality Ultrasonic nano material dispersion equipment

Parameter

| Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

| Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

| Power | 1000 W | 2000 W | 3000 W | 3000 W |

| Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

| Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Intensity of sound | 20 W/cm² | 40 W/cm² | 60 W/cm² | 60 W/cm² |

| Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

| Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Description

Ultrasonic nano-material dispersion system uses the principle of ultrasound to quickly and uniformly disperse the agglomeration of nano-materials physically and wetly, thus thoroughly breaking through this technical difficulty. Realize large-scale production equipment to meet customer's multi-type and different levels of industrial production needs. According to the difference of different media, concentration and process, the distribution and intensity of ultrasonic cavitation field (sound field) are not the same. Researchers can use ultrasonic equipment to control and calibrate the cavitation effect in the liquid, so as to solve the problem of industrial production. problem.

In recent years, nanomaterial B has been widely used in various industries to optimize the performance of materials. For example, adding graphene paint to the battery can greatly extend the service life of the battery, while adding silicon oxide to the glass can increase the transparency and robustness of the glass.

The core content of nanotechnology is how to solve the problem of nanoparticle agglomeration. Because nanoparticle itself is very easy to agglomerate, it is very difficult to obtain a single dispersed nanoparticle. How to uniformly disperse nanoparticles into the matrix is the key technology of nanotechnology.

In order to obtain excellent nanoparticles, an effective method is required. Ultrasonic cavitation immediately forms countless high-pressure and low-pressure areas in the solution. These high-pressure and low-pressure areas continuously collide with each other to generate strong shear force, depolymerize and reduce the size of the material. Ultrasonic waves used in the dispersion of nano-materials generally require relatively large sound pressure and ultrasonic amplitude. Therefore, horn type, that is, probe type, is more commonly used at present.

Recommendations

1. If you are new to nano materials and want to understand the effect of ultrasonic dispersion, you can use 1000W / 1500W laboratory materials.

2. If you are a small and medium enterprise that handles less than 5 tons of liquid per day, you can choose to add an ultrasonic probe to the reaction tank. You can use a 3000W probe.

3. If it is a large enterprise that needs to process dozens of tons or even hundreds of tons of liquid every day, an external ultrasonic circulation system is required. Multiple sets of ultrasonic equipment can process the circulation at the same time to achieve the desired effect.

Features

1. Unique focusing tool head design, higher energy concentration, larger amplitude and better homogenization effect.

2 The ultrasonic treatment process can be controlled, so the terminal state of the dispersion is also controllable, thereby greatly reducing the damage to the solution components.

3 It can disperse materials to nanometer level, and can handle high-viscosity solutions. The equipment can be equipped with PLC control, which makes the operation easier and the effect is more precise

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!