loading

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-W20 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 2600w |

|---|---|---|---|

| Type | Digital | Weight | 10kg |

| Excitemen | Separate Excitation | Screen | Touch Screen |

| Application | Welding,cutting,liquid Proccessor | ||

| High Light | 2600w Ultrasonic Generator 20khz,2600w Ultrasonic Power Supply,Digital Ultrasonic Generator 20khz | ||

20khz 2600w Ultrasonic Welding Generator RPS-DG4200 For Ultrasonic Welding

20khz 2600w High Power Ultrasonic Generator for ultrasonic welding

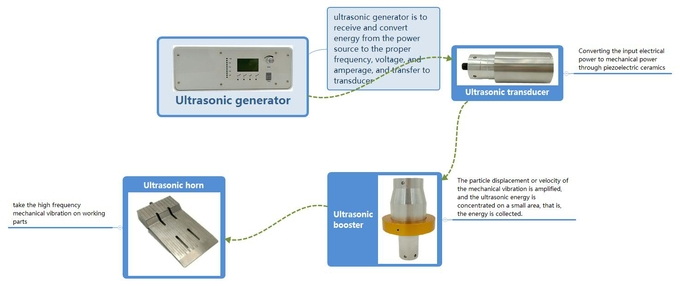

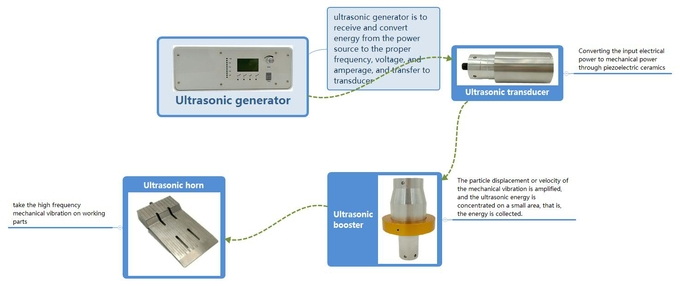

What's ultrasonic generator?

Ultrasonic generator, usually called ultrasonic power supply. Its function is to convert our mains (220V 110V or 380V, 50 or 60Hz) into a high frequency AC signal that matches the ultrasonic transducer. From the form of the amplifying circuit, a linear amplifying circuit and a switching power supply circuit can be used, and the high-power ultrasonic power source generally adopts a circuit form of a switching power supply in terms of conversion efficiency. Linear power supplies also have their own application range, which has the advantage that the circuit can be not strictly required.

Matching allows the operating frequency to change continuously and continuously. From the current situation in the ultrasound industry, ultrasonic generators are mainly divided into self-excited and separate excited power supply.

The principle of the ultrasonic generator is to first generate a signal of a specific frequency by a signal generator, which may be a sinusoidal signal or a pulse signal. This specific frequency is the frequency of the transducer, and is generally applied to ultrasonic in an ultrasonic device. The frequency is 20KHz, 25KHz, 28KHz, 33KHz, 40KHz, 60KHz,70khz, 100KHz.

Advantages

1. High stability: All-digital integrated circuits, use of US imports of high- performance processors interference, while reducing the number of components, simplify the hardware structure, thereby improving the reliability of the system.

2. Automatic frequency tracking: Digital frequency synthesis technology combined with digital phase-locked loop frequency tracking of complex control technology, can eliminate the temperature, static load, machining area, tool wear and other factors drift disadvantages of conventional analog regulator insurmountable, conducive parameter adjustment, easy modification by software, easily adjust the control scheme and achieve a variety of new control strategies.

3. Strong output: The use of IGBT power modules plus his excited oscillation circuit structure, the output power is more than 1.5 times that of conventional self-excited circuit.

4. Amplitude stepless adjustment: Amplitude can instantly increase or decrease in the adjustment process, also can be micro adjusted, can effectively prevent the perfect size pieces of plastic welding, effectively reducing wear shock, burns and so on. Defective amplitude setting range of 10% to 100%.

5. Intelligent three protection and fault alarm: Die-current protection, frequency offset protection, total output is too large to protect. Equipment failure, the generator will stop working, and make the appropriate cause of the malfunction prompts until technician troubleshooting.

6. Intelligent closed-loop amplitude control technology to achieve the amplitude adjustment, independent of input supply voltage and load fluctuations affect the amplitude of the output remains constant.

7. Two kinds of welding mode switch back and forth, so that a higher precision welding, soldering and better results.

Operation instructions

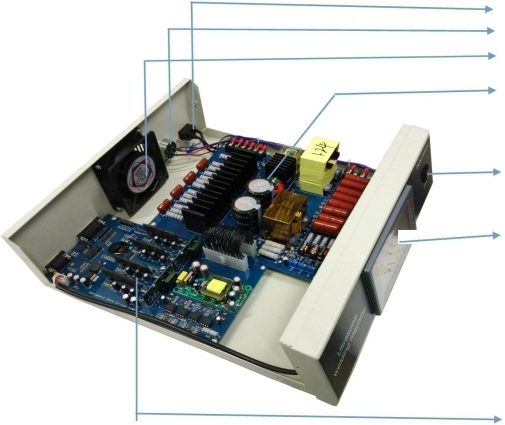

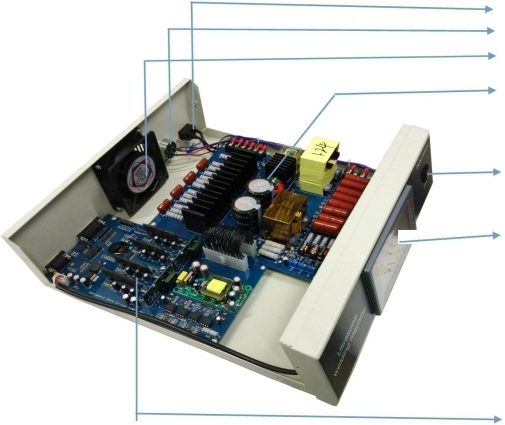

First. Ultrasonic generator structure

SECOND. Instructions of wire connection

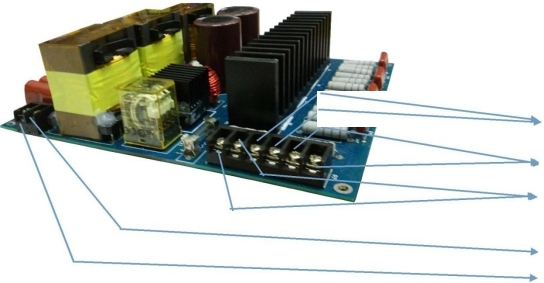

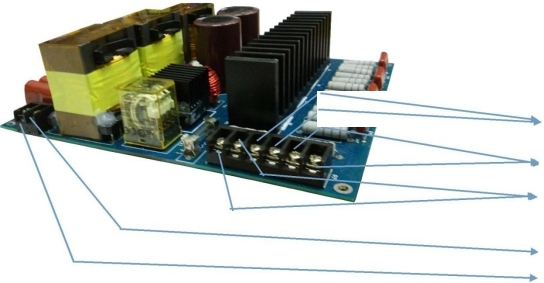

1. Wire connection of inner main board.

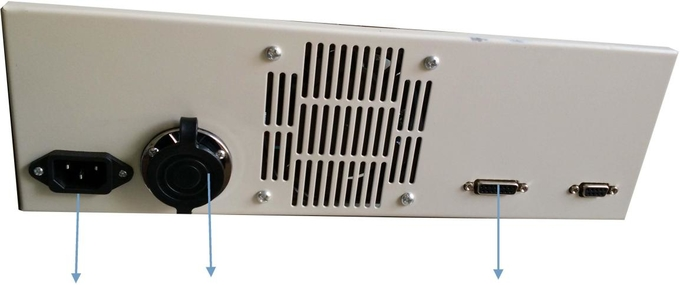

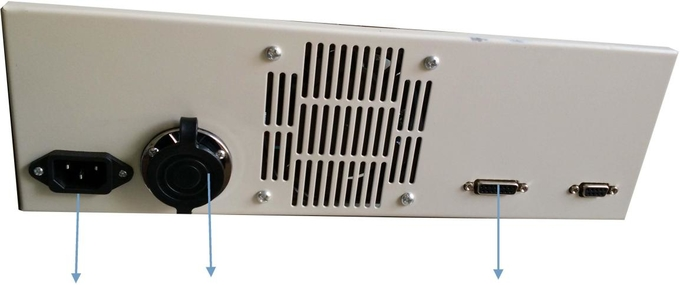

1. Wire connection of outer box.

1. Wire connection of 15-pin connector (refer to below picture)

1 and 2 the interior is connected, is Public 24V

2 Yellow Public 24V-

3 ![]() External emit ultrasonic waves control, for a long time to issue an ultrasonic wave electric box, standard plastic welder do not connect.

External emit ultrasonic waves control, for a long time to issue an ultrasonic wave electric box, standard plastic welder do not connect.

| 6.8 | Green | Start up | |

| 7 | Red | Stop | |

| 9 | Orange | 24v+ | |

| 10 | Black | Drop the solenoid valve | with 9 connect solenoid valve |

| 11 | white | Rise the solenoid valve | Taken up solenoid valve (solenoid valve 4V230C |

![]() depth section dedicated wiring, standard machine is not connected)

depth section dedicated wiring, standard machine is not connected)

12 Electrical box failure alarm output signal with 9 connect relay Alarm

13 Welding end signal with 9 connect relay Alarm 10 11 12 13 14 15

| Frequency | 20Khz | Power | 2600w |

|---|---|---|---|

| Type | Digital | Weight | 10kg |

| Excitemen | Separate Excitation | Screen | Touch Screen |

| Application | Welding,cutting,liquid Proccessor | ||

| High Light | 2600w Ultrasonic Generator 20khz,2600w Ultrasonic Power Supply,Digital Ultrasonic Generator 20khz | ||

20khz 2600w Ultrasonic Welding Generator RPS-DG4200 For Ultrasonic Welding

20khz 2600w High Power Ultrasonic Generator for ultrasonic welding

What's ultrasonic generator?

Ultrasonic generator, usually called ultrasonic power supply. Its function is to convert our mains (220V 110V or 380V, 50 or 60Hz) into a high frequency AC signal that matches the ultrasonic transducer. From the form of the amplifying circuit, a linear amplifying circuit and a switching power supply circuit can be used, and the high-power ultrasonic power source generally adopts a circuit form of a switching power supply in terms of conversion efficiency. Linear power supplies also have their own application range, which has the advantage that the circuit can be not strictly required.

Matching allows the operating frequency to change continuously and continuously. From the current situation in the ultrasound industry, ultrasonic generators are mainly divided into self-excited and separate excited power supply.

The principle of the ultrasonic generator is to first generate a signal of a specific frequency by a signal generator, which may be a sinusoidal signal or a pulse signal. This specific frequency is the frequency of the transducer, and is generally applied to ultrasonic in an ultrasonic device. The frequency is 20KHz, 25KHz, 28KHz, 33KHz, 40KHz, 60KHz,70khz, 100KHz.

Advantages

1. High stability: All-digital integrated circuits, use of US imports of high- performance processors interference, while reducing the number of components, simplify the hardware structure, thereby improving the reliability of the system.

2. Automatic frequency tracking: Digital frequency synthesis technology combined with digital phase-locked loop frequency tracking of complex control technology, can eliminate the temperature, static load, machining area, tool wear and other factors drift disadvantages of conventional analog regulator insurmountable, conducive parameter adjustment, easy modification by software, easily adjust the control scheme and achieve a variety of new control strategies.

3. Strong output: The use of IGBT power modules plus his excited oscillation circuit structure, the output power is more than 1.5 times that of conventional self-excited circuit.

4. Amplitude stepless adjustment: Amplitude can instantly increase or decrease in the adjustment process, also can be micro adjusted, can effectively prevent the perfect size pieces of plastic welding, effectively reducing wear shock, burns and so on. Defective amplitude setting range of 10% to 100%.

5. Intelligent three protection and fault alarm: Die-current protection, frequency offset protection, total output is too large to protect. Equipment failure, the generator will stop working, and make the appropriate cause of the malfunction prompts until technician troubleshooting.

6. Intelligent closed-loop amplitude control technology to achieve the amplitude adjustment, independent of input supply voltage and load fluctuations affect the amplitude of the output remains constant.

7. Two kinds of welding mode switch back and forth, so that a higher precision welding, soldering and better results.

Operation instructions

First. Ultrasonic generator structure

SECOND. Instructions of wire connection

1. Wire connection of inner main board.

1. Wire connection of outer box.

1. Wire connection of 15-pin connector (refer to below picture)

1 and 2 the interior is connected, is Public 24V

2 Yellow Public 24V-

3 ![]() External emit ultrasonic waves control, for a long time to issue an ultrasonic wave electric box, standard plastic welder do not connect.

External emit ultrasonic waves control, for a long time to issue an ultrasonic wave electric box, standard plastic welder do not connect.

| 6.8 | Green | Start up | |

| 7 | Red | Stop | |

| 9 | Orange | 24v+ | |

| 10 | Black | Drop the solenoid valve | with 9 connect solenoid valve |

| 11 | white | Rise the solenoid valve | Taken up solenoid valve (solenoid valve 4V230C |

![]() depth section dedicated wiring, standard machine is not connected)

depth section dedicated wiring, standard machine is not connected)

12 Electrical box failure alarm output signal with 9 connect relay Alarm

13 Welding end signal with 9 connect relay Alarm 10 11 12 13 14 15

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!