loading

| Availability: | |

|---|---|

| Quantity: | |

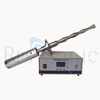

RPS-SONO20

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPSS20-2000 |

| Minimum Order Quantity | 1set |

| Price | negotiation |

| Packaging Details | Foam And Wood Box |

| Delivery Time | 3days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 200 sets per month |

Description:

Ultrasonic dispersion is a highly effective, versatile technology for achieving uniform and stable dispersions, critical for advanced material and product development.

Ultrasonic nano-dispersion refers to the use of ultrasonic technology to effectively disperse nanoparticles into a liquid medium, breaking up agglomerates and ensuring a uniform distribution. This process is widely used in nanotechnology, material sciences, and industrial applications where stable and consistent dispersions are required.

Ultrasonic Wave Generation: High-frequency sound waves (usually 20–40 kHz) are introduced into the liquid via a transducer.

Cavitation Effect: The ultrasonic waves create microscopic bubbles in the liquid. These bubbles collapse violently, generating intense shear forces, localized high temperatures, and pressures.

Breaking Agglomerates:

Nanoparticles, which tend to cluster due to van der Waals forces or static electricity, are separated by the cavitation-induced shear forces.

This results in a stable, evenly distributed nanoparticle dispersion.

High Efficiency: Rapidly disperses particles, reducing processing time.

Uniform Distribution: Produces stable dispersions with consistent particle size.

Versatility: Works with a wide range of materials, from nanoparticles to pigments.

Scalability: Suitable for laboratory research and large-scale industrial production.

No Chemical Additives: Achieves dispersion without the need for stabilizers or surfactants in some cases.

Sonication Power and Time: Excessive sonication can damage nanoparticles or alter their properties.

Medium Compatibility: Ensure the solvent and nanoparticles are compatible for stable dispersion.

Temperature Management: Avoid overheating sensitive materials by incorporating cooling systems.

Stabilizers: Use surfactants, polymers, or other stabilizing agents when necessary to prevent re-agglomeration.

| Item | Parameter |

| Frequency | 20Khz |

| Power | 1000W |

| Capacity | 5L |

| Horn diameter | 16mm |

| Probe dip depth | 80mm |

| Generator | Digital generator |

Description:

Ultrasonic dispersion is a highly effective, versatile technology for achieving uniform and stable dispersions, critical for advanced material and product development.

Ultrasonic nano-dispersion refers to the use of ultrasonic technology to effectively disperse nanoparticles into a liquid medium, breaking up agglomerates and ensuring a uniform distribution. This process is widely used in nanotechnology, material sciences, and industrial applications where stable and consistent dispersions are required.

Ultrasonic Wave Generation: High-frequency sound waves (usually 20–40 kHz) are introduced into the liquid via a transducer.

Cavitation Effect: The ultrasonic waves create microscopic bubbles in the liquid. These bubbles collapse violently, generating intense shear forces, localized high temperatures, and pressures.

Breaking Agglomerates:

Nanoparticles, which tend to cluster due to van der Waals forces or static electricity, are separated by the cavitation-induced shear forces.

This results in a stable, evenly distributed nanoparticle dispersion.

High Efficiency: Rapidly disperses particles, reducing processing time.

Uniform Distribution: Produces stable dispersions with consistent particle size.

Versatility: Works with a wide range of materials, from nanoparticles to pigments.

Scalability: Suitable for laboratory research and large-scale industrial production.

No Chemical Additives: Achieves dispersion without the need for stabilizers or surfactants in some cases.

Sonication Power and Time: Excessive sonication can damage nanoparticles or alter their properties.

Medium Compatibility: Ensure the solvent and nanoparticles are compatible for stable dispersion.

Temperature Management: Avoid overheating sensitive materials by incorporating cooling systems.

Stabilizers: Use surfactants, polymers, or other stabilizing agents when necessary to prevent re-agglomeration.

| Item | Parameter |

| Frequency | 20Khz |

| Power | 1000W |

| Capacity | 5L |

| Horn diameter | 16mm |

| Probe dip depth | 80mm |

| Generator | Digital generator |

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment