loading

| Availability: | |

|---|---|

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-AT50 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

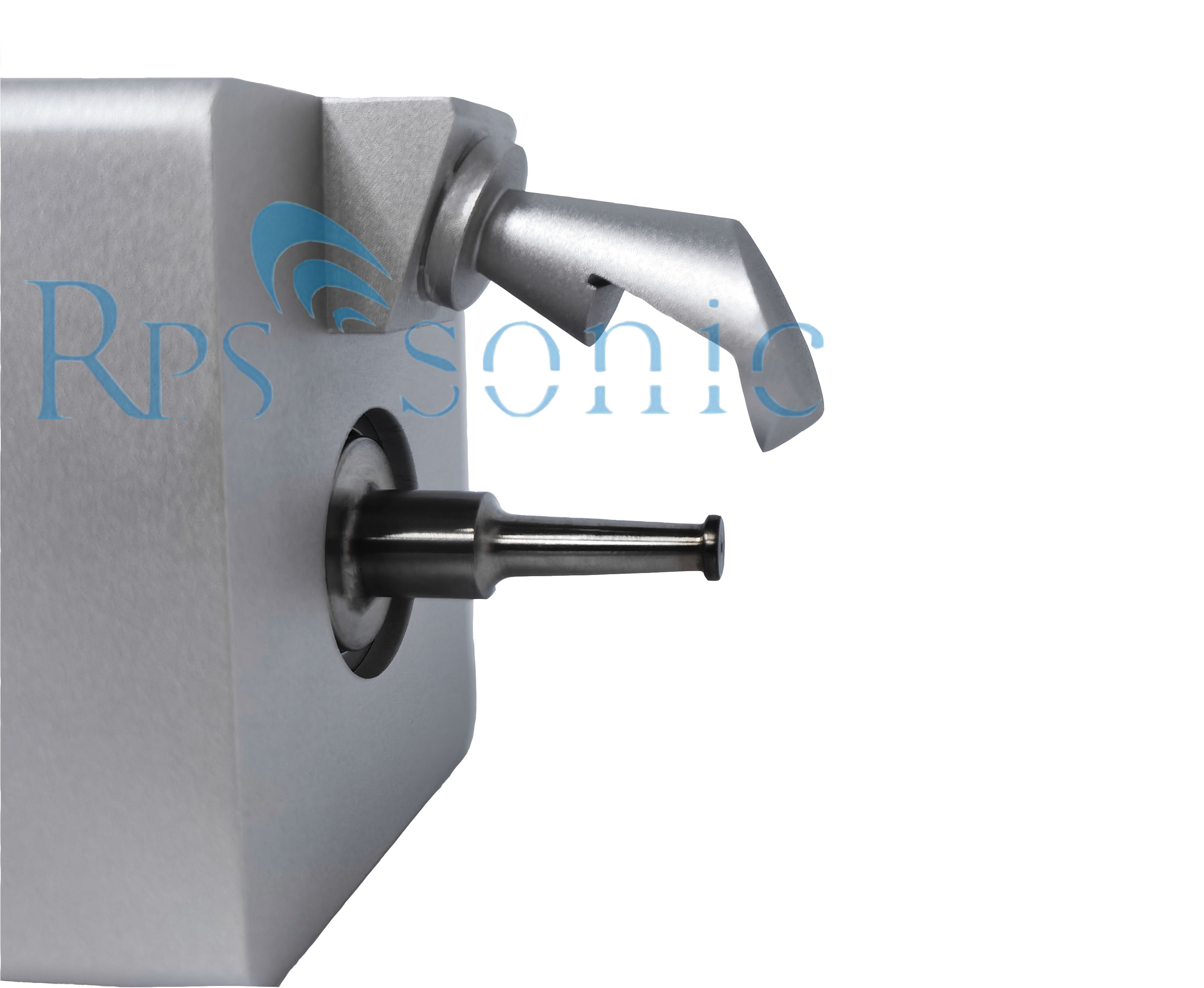

50Khz High Frequency Ultrasonic Atomization Nozzle for antimicrobial coatings

Paramater

| Item | Parameter |

| Frequency | 50Khz |

| Power | 10~100w |

| FLOW RATE (ml/min) | 0~20ml/min |

| Spray width | 2~200mm |

| Solution utilization | above 98% |

Description

The working principle of ultrasonic spraying equipment is based on ultrasonic atomizing nozzle technology. It uses the energy of ultrasound to break up water or liquid to form tiny particles ranging from a few microns to more than 100 microns. Ultrasonic nozzles work by converting high-frequency sound waves into mechanical energy, which is transferred to the liquid to generate standing waves. When the liquid leaves the atomizing surface of the nozzle, it is broken into a fine mist of uniform micron-sized droplets, thus achieving atomization.

Features

1. High precision and high uniformity: Ultrasonic spraying equipment can achieve better uniformity and higher precision, and is suitable for high-uniformity submicron and nanoscale thin film coating.

2. Save paint: The ultrasonic nozzle can atomize without air pressure assistance, which significantly reduces paint splashing during the spraying process and improves paint utilization.

3. High efficiency and energy saving: The liquid is transferred to the spray head through its own gravity or a low-pressure pump and achieves continuous or intermittent atomization. It has low energy consumption, simple equipment and low failure rate.

4. High controllability: Ultrasonic spray equipment is easy to adjust and control, and parameters such as spray volume, spray angle, and spray distance can be adjusted according to actual needs.

5. Widely used: This equipment is mainly used in fuel cells, thin film photovoltaic cells, thin film solar coatings, perovskite solar cells, solar cells, graphene coatings, silicon photovoltaic cells, glass coatings, electronic circuits and other industries.

Application

Spraying in the field of new energy: fuel cells, thin-film solar cells

Spraying in the glass field: anti-reflection AR, hydrophilic and hydrophobic coating, conductive layer, etc.

Spraying in the electronic field: flux, photoresist, conformal paint

Non-woven fabric and textile spraying

Spraying in the biomedical field

Conductive film: conductive films such as carbon nanotubes, graphene, nano silver, etc.

50Khz High Frequency Ultrasonic Atomization Nozzle for antimicrobial coatings

Paramater

| Item | Parameter |

| Frequency | 50Khz |

| Power | 10~100w |

| FLOW RATE (ml/min) | 0~20ml/min |

| Spray width | 2~200mm |

| Solution utilization | above 98% |

Description

The working principle of ultrasonic spraying equipment is based on ultrasonic atomizing nozzle technology. It uses the energy of ultrasound to break up water or liquid to form tiny particles ranging from a few microns to more than 100 microns. Ultrasonic nozzles work by converting high-frequency sound waves into mechanical energy, which is transferred to the liquid to generate standing waves. When the liquid leaves the atomizing surface of the nozzle, it is broken into a fine mist of uniform micron-sized droplets, thus achieving atomization.

Features

1. High precision and high uniformity: Ultrasonic spraying equipment can achieve better uniformity and higher precision, and is suitable for high-uniformity submicron and nanoscale thin film coating.

2. Save paint: The ultrasonic nozzle can atomize without air pressure assistance, which significantly reduces paint splashing during the spraying process and improves paint utilization.

3. High efficiency and energy saving: The liquid is transferred to the spray head through its own gravity or a low-pressure pump and achieves continuous or intermittent atomization. It has low energy consumption, simple equipment and low failure rate.

4. High controllability: Ultrasonic spray equipment is easy to adjust and control, and parameters such as spray volume, spray angle, and spray distance can be adjusted according to actual needs.

5. Widely used: This equipment is mainly used in fuel cells, thin film photovoltaic cells, thin film solar coatings, perovskite solar cells, solar cells, graphene coatings, silicon photovoltaic cells, glass coatings, electronic circuits and other industries.

Application

Spraying in the field of new energy: fuel cells, thin-film solar cells

Spraying in the glass field: anti-reflection AR, hydrophilic and hydrophobic coating, conductive layer, etc.

Spraying in the electronic field: flux, photoresist, conformal paint

Non-woven fabric and textile spraying

Spraying in the biomedical field

Conductive film: conductive films such as carbon nanotubes, graphene, nano silver, etc.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment