loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-T40 |

| Minimum Order Quantity | 5 |

| Packaging Details | CARTON |

| Delivery Time | 3 work days after payment |

| Payment Terms | T/T, Western Union |

| Supply Ability | 100sets |

| Frequency | 40Khz | Power | 700W |

|---|---|---|---|

| Material | Aluminum | Application | Ultrasonic Welding Machine/40K Ultrasonic Cutting Machine/Ultrasonic Sewing Machine |

| High Light | Industrial Ultrasonic Welding Transducer,ultrasonic welding transducer 40khz,M10 ultrasonic sewing machine transducer | ||

Specifications:

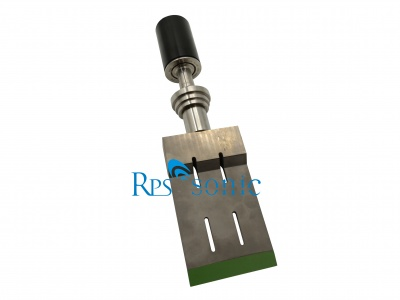

| Model | RPS-3040-4Z |

| Frequency | 40khz |

| Output power | 700watt |

| Joint bolt | M10 |

| Ceramic disc Diameter | 30mm |

| Quantity of Ceramic discs | 4 pcs |

| Capacitance | 5.5~6.2nf |

| Amplitude | 4um |

| Application | Welding |

Description:

Transducer, in electronics, a device that converts electric energy into some other form of energy, especially the application of mechanical energy in industry is more and more significant.

We mainly supply two kinds of Ultrasonic transducers: NTK type and Branson type. Widely used in ultrasonic welding, ultrasonic cutting,ultrasonic sewing machine,ultrasonic sonochemistry, ultrasonic wire stripping machine,ultrasonic nebulizer,Ultrasonic riveting machine.

The ultrasonic cutter vibrates its blade with an amplitude of 10 - 70 µm in the longitudinal direction. The vibration is microscopic, so it cannot be seen. The movement repeats 20,000 - 40,000 times per second (20 - 40 kHz). Because of this movement, the ultrasonic cutter can easily cut resin, rubber, nonwoven cloths, film, composite materials in which various products are superposed, and food.

The ultrasonic cutter is composed of a "transducer" that generates vibration and an "oscillator" that drives the transducer. A piezoelectric element is used for the transducer. When voltage is applied, the piezoelectric element displaces the transducer by a few micrometers. Periodically applying voltage generates vibration. Each object has its special frequency, by which the object is stable and easy to vibrate. By adding an external force that corresponds to that special frequency, a small force can obtain a large vibration. This phenomenon is called resonance. In the ultrasonic cutter, the piezoelectric element generates a force that resonates the whole body, from the transducer to the blade tip, generating a large vibration at the tip. The oscillator periodically generates voltage to resonate and drive the transducer. Using a component of the ultrasonic cutter called the horn to ring the cross-sectional area, from the piezoelectric element to the blade tip, can obtain a larger vibration.

Applications:

Our transducer can applied in the following ultrasonic machines:

| Ultrasonic welding machine | All material with thermoplasticity can use Ultrasonic welding machine , it can welding the material more easy and stable.Such like plastic, fabric, ABS, nonwovens. |

| Ultrasonic cutting machine | Ultrasonic food cutting is popular because the perfect edge. Ultrasonic cutting in packing area also welcomed, it can cutting and sealing at the same. |

| Ultrasonic sewing machine | Ultrasonic sewing can sewing the material without any cotton, and keep longer time. |

Competitive Advantage:

1. Imported ceramic discs and superior aluminum raw materials

2. Once assembled, the transducers are aged before testing and final assembly. The properties of piezoelectric materials can change with time and pressure, so a bit of time on the shelf prior to testing will identify nonconforming material.

3. One by one testing to ensure that each transducer performance are excellent.

4. In good heat resistance, can be used in a wide range of temperature with long life and high reliability.

Package&Shipping

| Frequency | 40Khz | Power | 700W |

|---|---|---|---|

| Material | Aluminum | Application | Ultrasonic Welding Machine/40K Ultrasonic Cutting Machine/Ultrasonic Sewing Machine |

| High Light | Industrial Ultrasonic Welding Transducer,ultrasonic welding transducer 40khz,M10 ultrasonic sewing machine transducer | ||

Specifications:

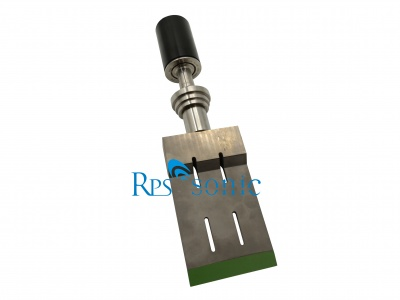

| Model | RPS-3040-4Z |

| Frequency | 40khz |

| Output power | 700watt |

| Joint bolt | M10 |

| Ceramic disc Diameter | 30mm |

| Quantity of Ceramic discs | 4 pcs |

| Capacitance | 5.5~6.2nf |

| Amplitude | 4um |

| Application | Welding |

Description:

Transducer, in electronics, a device that converts electric energy into some other form of energy, especially the application of mechanical energy in industry is more and more significant.

We mainly supply two kinds of Ultrasonic transducers: NTK type and Branson type. Widely used in ultrasonic welding, ultrasonic cutting,ultrasonic sewing machine,ultrasonic sonochemistry, ultrasonic wire stripping machine,ultrasonic nebulizer,Ultrasonic riveting machine.

The ultrasonic cutter vibrates its blade with an amplitude of 10 - 70 µm in the longitudinal direction. The vibration is microscopic, so it cannot be seen. The movement repeats 20,000 - 40,000 times per second (20 - 40 kHz). Because of this movement, the ultrasonic cutter can easily cut resin, rubber, nonwoven cloths, film, composite materials in which various products are superposed, and food.

The ultrasonic cutter is composed of a "transducer" that generates vibration and an "oscillator" that drives the transducer. A piezoelectric element is used for the transducer. When voltage is applied, the piezoelectric element displaces the transducer by a few micrometers. Periodically applying voltage generates vibration. Each object has its special frequency, by which the object is stable and easy to vibrate. By adding an external force that corresponds to that special frequency, a small force can obtain a large vibration. This phenomenon is called resonance. In the ultrasonic cutter, the piezoelectric element generates a force that resonates the whole body, from the transducer to the blade tip, generating a large vibration at the tip. The oscillator periodically generates voltage to resonate and drive the transducer. Using a component of the ultrasonic cutter called the horn to ring the cross-sectional area, from the piezoelectric element to the blade tip, can obtain a larger vibration.

Applications:

Our transducer can applied in the following ultrasonic machines:

| Ultrasonic welding machine | All material with thermoplasticity can use Ultrasonic welding machine , it can welding the material more easy and stable.Such like plastic, fabric, ABS, nonwovens. |

| Ultrasonic cutting machine | Ultrasonic food cutting is popular because the perfect edge. Ultrasonic cutting in packing area also welcomed, it can cutting and sealing at the same. |

| Ultrasonic sewing machine | Ultrasonic sewing can sewing the material without any cotton, and keep longer time. |

Competitive Advantage:

1. Imported ceramic discs and superior aluminum raw materials

2. Once assembled, the transducers are aged before testing and final assembly. The properties of piezoelectric materials can change with time and pressure, so a bit of time on the shelf prior to testing will identify nonconforming material.

3. One by one testing to ensure that each transducer performance are excellent.

4. In good heat resistance, can be used in a wide range of temperature with long life and high reliability.

Package&Shipping

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!