loading

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-C40 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 40Khz | Power | 300w |

|---|---|---|---|

| Horn Material | Titanium | Generator | Digital |

| Voltage | 220/110V | Application | Ultrasonic Fabric Cutter |

| Weight | 6kg | Warranty | One Year |

| Blade Thickness | 0.6mm | ||

| High Light | 300 Watt Ultrasonic Cutting Device,Titanium Horn Handheld Ultrasonic Cutter,0.6mm Blade Ultrasonic Cutting Equipment | ||

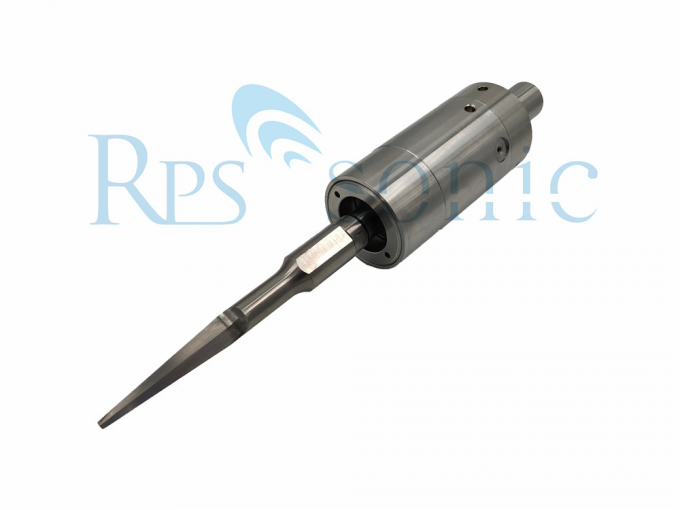

Handheld 40Khz Ultrasonic Cutting Device 300 Watt For Honeycomb

40Khz 300w Handheld Ultrasonic Cutting Device for honeycomb cutting

Parameter

| Frequency | 40Khz |

| Frequency adjustment | Auto-tracking type |

| Max. power output | 300W |

| Power output | Infinitive adjustment |

| Power supply | AC200V 50/60Hz |

| Outer dimension (mm) | 120*120*380 |

| Weight | 6kg |

| Blade thickness | 0.6mm |

Introduction

Honeycomb materials and structures are increasingly used in the aeronautics industry. Machining these materials using traditional methods is often complex, costly, and unsatisfactory in terms of quality and accuracy.

CRENO has developed a unique solution, qualified by aerospace, for these materials by combining the advantages of the ultrasonic cutting process and traditional milling machines.

This kind cutting machines combine traditional milling and ultrasonic cutting quality in one machine. It is therefore possible to machine composite skins, honeycomb materials, and bonded parts. This solution offers the opportunity to work on a wide range of materials and shapes, in particular when cutting small parts at high-speeds.

RPS-SONIC is one of the first manufacturers to offer innovative hard metal monolithic knives. This monolithic design made of solid carbide ensures the best rigidity and the best swinging behaviour of the knife and thus, overcomes traditional problems of standard brazed knives like non-consistency in quality and response when in vibration.

RPS-SONIC offers innovative high frequency knives, especially developed for stable cutting processes of composite materials. Unlike the standard version from other manufacturers (brazed tools with steel connection and Tungsten Carbide blades), our knives are solid carbide tools.

Application range

▲ Components for aerospace industry:

Wing panels, Floor panels, Doors

▲ Components for automotive industry:

Isolation panels, Elements for the seats

▲ Food industry:

For the food industry, we only use FDA approved carbide grades that have been specifically designed for an optimal performance of our ultrasonic cutting knives.

Advantages & Benefits

Single-source production

We master the entire process chain from the raw material to the finished tool and thus, we can always guarantee a stable and high quality.

Application-oriented research and development

For the solid carbide knives, we have developed a specific Tungsten Carbide grade with an improved relation of hardness, toughness and transverse rupture strength.

Individual solution-expertise

Our engineering team can work with OEM’s to develop individual solutions for each ultrasonic cutting system to achieve the most precise and stable cutting processes. Please contact us for an informal discussion on how we can support you!

High class engineering

We guarantee a highly stable and precise cutting process thanks to:

▲ Solid thread connection with improved tightening torque resistance

▲ Accurate execution of every cutting edge for improved sharpness

▲ Accurate dimensional inspection after every production step

It goes without saying that the knives have been tested successfully under real-life and severe cutting conditions.

Optimised production

Thanks to our assimilated production process and accurate inspections, we offer knives with near net shape and the highest sharpness on the market.

| Frequency | 40Khz | Power | 300w |

|---|---|---|---|

| Horn Material | Titanium | Generator | Digital |

| Voltage | 220/110V | Application | Ultrasonic Fabric Cutter |

| Weight | 6kg | Warranty | One Year |

| Blade Thickness | 0.6mm | ||

| High Light | 300 Watt Ultrasonic Cutting Device,Titanium Horn Handheld Ultrasonic Cutter,0.6mm Blade Ultrasonic Cutting Equipment | ||

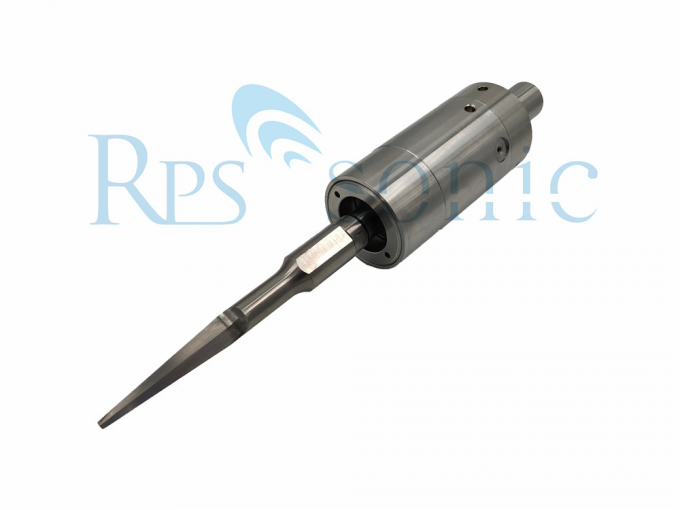

Handheld 40Khz Ultrasonic Cutting Device 300 Watt For Honeycomb

40Khz 300w Handheld Ultrasonic Cutting Device for honeycomb cutting

Parameter

| Frequency | 40Khz |

| Frequency adjustment | Auto-tracking type |

| Max. power output | 300W |

| Power output | Infinitive adjustment |

| Power supply | AC200V 50/60Hz |

| Outer dimension (mm) | 120*120*380 |

| Weight | 6kg |

| Blade thickness | 0.6mm |

Introduction

Honeycomb materials and structures are increasingly used in the aeronautics industry. Machining these materials using traditional methods is often complex, costly, and unsatisfactory in terms of quality and accuracy.

CRENO has developed a unique solution, qualified by aerospace, for these materials by combining the advantages of the ultrasonic cutting process and traditional milling machines.

This kind cutting machines combine traditional milling and ultrasonic cutting quality in one machine. It is therefore possible to machine composite skins, honeycomb materials, and bonded parts. This solution offers the opportunity to work on a wide range of materials and shapes, in particular when cutting small parts at high-speeds.

RPS-SONIC is one of the first manufacturers to offer innovative hard metal monolithic knives. This monolithic design made of solid carbide ensures the best rigidity and the best swinging behaviour of the knife and thus, overcomes traditional problems of standard brazed knives like non-consistency in quality and response when in vibration.

RPS-SONIC offers innovative high frequency knives, especially developed for stable cutting processes of composite materials. Unlike the standard version from other manufacturers (brazed tools with steel connection and Tungsten Carbide blades), our knives are solid carbide tools.

Application range

▲ Components for aerospace industry:

Wing panels, Floor panels, Doors

▲ Components for automotive industry:

Isolation panels, Elements for the seats

▲ Food industry:

For the food industry, we only use FDA approved carbide grades that have been specifically designed for an optimal performance of our ultrasonic cutting knives.

Advantages & Benefits

Single-source production

We master the entire process chain from the raw material to the finished tool and thus, we can always guarantee a stable and high quality.

Application-oriented research and development

For the solid carbide knives, we have developed a specific Tungsten Carbide grade with an improved relation of hardness, toughness and transverse rupture strength.

Individual solution-expertise

Our engineering team can work with OEM’s to develop individual solutions for each ultrasonic cutting system to achieve the most precise and stable cutting processes. Please contact us for an informal discussion on how we can support you!

High class engineering

We guarantee a highly stable and precise cutting process thanks to:

▲ Solid thread connection with improved tightening torque resistance

▲ Accurate execution of every cutting edge for improved sharpness

▲ Accurate dimensional inspection after every production step

It goes without saying that the knives have been tested successfully under real-life and severe cutting conditions.

Optimised production

Thanks to our assimilated production process and accurate inspections, we offer knives with near net shape and the highest sharpness on the market.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!