loading

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-C35 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 35Khz | Power | 500w |

|---|---|---|---|

| Horn Material | Titanium | Generator | Digital |

| Voltage | 220/110V | Application | Ultrasonic Fabric Cutter |

| Weight | 6kg | Warranty | One Year |

| High Light | Infinitive Adjustment Ultrasonic Cutting Device,Ultrasonic Cutting Device 35Khz,Titanium Knife Ultrasonic Cutting Equipment | ||

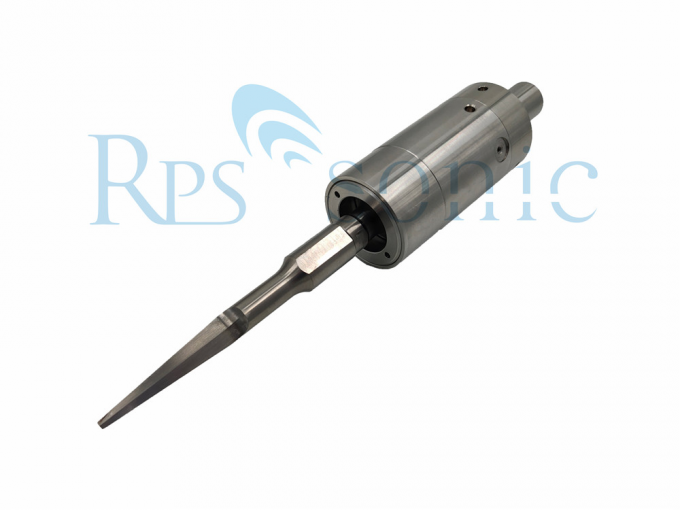

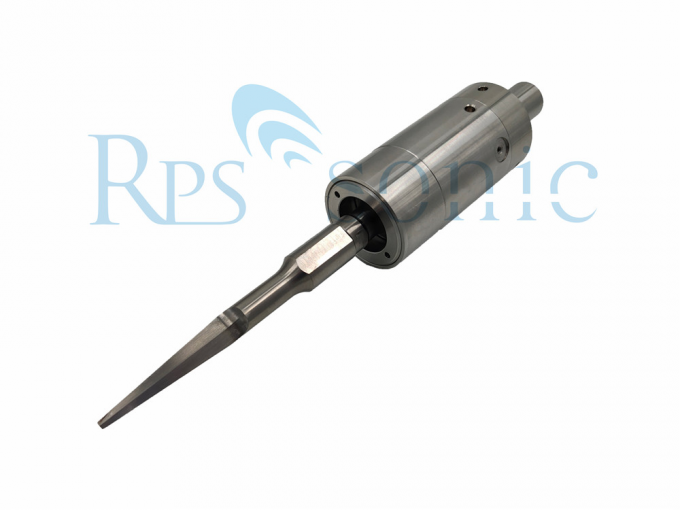

Titanium Knife Ultrasonic Cutting Device For ABS PE PVC PC PP

Ultrasound Plastic Cutting Knife Machine for ABS PE PVC PC PP Acrylic with SK51 Die Steel Cutting Knife

Parameter

| Frequency | 35Khz |

| Frequency adjustment | Auto-tracking type |

| Max. power output | 300W |

| Power output | Infinitive adjustment |

| Power supply | AC200V 50/60Hz |

| Outer dimension (mm) | 120*120*380 |

| Weight | 6kg |

| Blade thickness | 0.6mm |

Description

An ultrasonic knife is a modern invention. Its main role is to cut through thick materials without putting any strain or pressure on the user. Basically, such knives rely on ultrasonic sound waves. Their vibrations are microscopic and almost impossible to notice. From this point of view, you no longer need that classic sawing motion when trying to cut a problematic material. These days, ultrasonic knives have made it to both residential and professional applications.

Choosing the best ultrasonic cutter could be a bit daunting though. The technology is quite new in residential applications, but more and more people switch to this modern alternative. There are a few good options out there, as well as some products that stand out in the crowd. Knowing more about these knives will help you make a more informed decision. At the same time, you need to double-check a few reviews and recommendations from previous buyers.

Many machines are relying on ultrasonic technology out there. Cutters have been introduced to this range to go through materials with too little or too much resistance. To understand how they work, imagine up to 40,000 vibrations per second. This kind of movement allows the knife to cut through composite materials, rubber, and resin without any hassle at all. You will get fine and straight cuts without struggling at all.

Each item out there comes with its own unique frequency. At that point, the respective item is stable, but also easy to oscillate. An external force that can handle that frequency brings in a bit of force, leading to an impressive oscillation. This procedure is referred to as resonance. At this point, the resonance is responsible for the cutting edge and the impressive oscillation. It sounds sophisticated, but the process is relatively simple to understand.

Versatile and powerful – RPS-SONIC’s ultrasonic cutter is one of the most appreciated options on the market. It is efficient, compact, and designed to last. What makes it so special is the extra efficiency when compared to other similar products. The cutting performance is about 30% higher than in other ultrasonic knives, meaning you can cut thicker and harder materials without facing any issues at all.

Extremely fast – Speed is one of the most important specifications in ultrasonic knives. The faster a knife is, the easier it will cut through all types of materials. This unit can vibrate up to 40,000 times per second. It is not just super-efficient, but it also minimizes the heating associated with this type of cutting procedure. Simply put, there are no risks associated with over current, voltage, or power.

Easy to use and comfortable – It might be a bit unusual to work with an ultrasonic cutter if you have never dealt with one before, but chances are you will get used to it in no time. The cutter is intuitive and easy to use. It makes no difference if you leave it on a desk or you need to perform cuts with the unit on your waist. Even those without strong grips – such as elders – can use this knife.

Delicate cuts – The knife is more suitable for delicate cuts. It is excellent for intricate details, small cuts, and tiny corrections. You can use pretty much any knife for a large cut, but things go difficult when it comes to delicacy. With this knife, anyone can be a professional in terms of DIY projects, plastic models, accessories, and so on.

| Frequency | 35Khz | Power | 500w |

|---|---|---|---|

| Horn Material | Titanium | Generator | Digital |

| Voltage | 220/110V | Application | Ultrasonic Fabric Cutter |

| Weight | 6kg | Warranty | One Year |

| High Light | Infinitive Adjustment Ultrasonic Cutting Device,Ultrasonic Cutting Device 35Khz,Titanium Knife Ultrasonic Cutting Equipment | ||

Titanium Knife Ultrasonic Cutting Device For ABS PE PVC PC PP

Ultrasound Plastic Cutting Knife Machine for ABS PE PVC PC PP Acrylic with SK51 Die Steel Cutting Knife

Parameter

| Frequency | 35Khz |

| Frequency adjustment | Auto-tracking type |

| Max. power output | 300W |

| Power output | Infinitive adjustment |

| Power supply | AC200V 50/60Hz |

| Outer dimension (mm) | 120*120*380 |

| Weight | 6kg |

| Blade thickness | 0.6mm |

Description

An ultrasonic knife is a modern invention. Its main role is to cut through thick materials without putting any strain or pressure on the user. Basically, such knives rely on ultrasonic sound waves. Their vibrations are microscopic and almost impossible to notice. From this point of view, you no longer need that classic sawing motion when trying to cut a problematic material. These days, ultrasonic knives have made it to both residential and professional applications.

Choosing the best ultrasonic cutter could be a bit daunting though. The technology is quite new in residential applications, but more and more people switch to this modern alternative. There are a few good options out there, as well as some products that stand out in the crowd. Knowing more about these knives will help you make a more informed decision. At the same time, you need to double-check a few reviews and recommendations from previous buyers.

Many machines are relying on ultrasonic technology out there. Cutters have been introduced to this range to go through materials with too little or too much resistance. To understand how they work, imagine up to 40,000 vibrations per second. This kind of movement allows the knife to cut through composite materials, rubber, and resin without any hassle at all. You will get fine and straight cuts without struggling at all.

Each item out there comes with its own unique frequency. At that point, the respective item is stable, but also easy to oscillate. An external force that can handle that frequency brings in a bit of force, leading to an impressive oscillation. This procedure is referred to as resonance. At this point, the resonance is responsible for the cutting edge and the impressive oscillation. It sounds sophisticated, but the process is relatively simple to understand.

Versatile and powerful – RPS-SONIC’s ultrasonic cutter is one of the most appreciated options on the market. It is efficient, compact, and designed to last. What makes it so special is the extra efficiency when compared to other similar products. The cutting performance is about 30% higher than in other ultrasonic knives, meaning you can cut thicker and harder materials without facing any issues at all.

Extremely fast – Speed is one of the most important specifications in ultrasonic knives. The faster a knife is, the easier it will cut through all types of materials. This unit can vibrate up to 40,000 times per second. It is not just super-efficient, but it also minimizes the heating associated with this type of cutting procedure. Simply put, there are no risks associated with over current, voltage, or power.

Easy to use and comfortable – It might be a bit unusual to work with an ultrasonic cutter if you have never dealt with one before, but chances are you will get used to it in no time. The cutter is intuitive and easy to use. It makes no difference if you leave it on a desk or you need to perform cuts with the unit on your waist. Even those without strong grips – such as elders – can use this knife.

Delicate cuts – The knife is more suitable for delicate cuts. It is excellent for intricate details, small cuts, and tiny corrections. You can use pretty much any knife for a large cut, but things go difficult when it comes to delicacy. With this knife, anyone can be a professional in terms of DIY projects, plastic models, accessories, and so on.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!