loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-3535-4D |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 35Khz | Power | 1200w |

|---|---|---|---|

| Ceramic Chips | 4PCS | Material | Alumium |

| Weight | 3kg | Application | Ultrasonic Welding |

| Capacitance | 11000~12000PF |

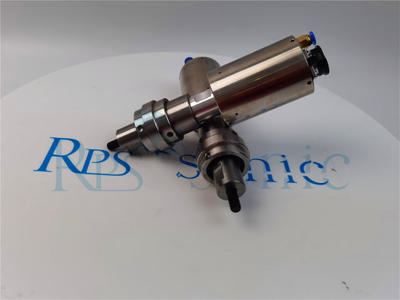

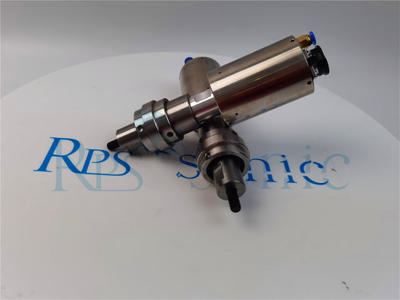

35kHZ Ultrasonic Welding Transducer with Titanium Booster with Closed Housing

| Frequency | 35 khz |

| Output power | 1200 watt |

| Joint bolt | M8*1.25 |

| Ceramic disc Diameter | 25 mm |

| Quantity of Ceramic discs | 4 pcs |

| Capacitance | 4nF |

| Amplitude | 10um |

| Application | welding machine |

Ultrasonic transducers are piezoelectric ceramics that resonate at ultrasonic frequencies and convert electrical signals into mechanical vibrations by the piezoelectric effect of the material. When the transducer is used as a transmitter, the electrical oscillating signal sent from the excitation source will cause a change in the electric or magnetic field in the electrical energy storage element of the transducer, which changes the mechanical vibration system of the transducer through some effort. A driving force is generated to cause it to vibrate, thereby propelling themedium in contact with the mechanical vibration system of the transducer to vibrate and radiate sound waves into the medium.

When an AC voltage is applied, piezo elements begin to oscillate. The extremely fast response in the microsecond range and below allow for ultrasound generation with frequencies of up to 20 MHz.

Ultrasonic applications can be classified in sensor applications and power ultrasound where the energy densities are higher and frequencies range from 20 to 800 kHz.

Power ultrasound can be used in medical applications, e.g. to crush kidney stones and for removing dental plaque, and industrial processes, such as cleaning and welding or bonding.

Advantages:

1. Heat resistance: It is made of high quality materials, has good heat resistance, low resonance impedance and low heat generation.

2. Strong structure: It is fastened with high quality standard steel bolts and has high reliability.

3. Electrical parameters: unique production process, digital equipment processing and assembly, high parameter performance and good consistency.

▏Warranty one year for transducer.

▏You can cantact us for technical inquiry any time.

▏We supply OEM service for oversea customer, also will keep Confidentiality for our customers.

▏Shipment by FED-EX/DHL

| Frequency | 35Khz | Power | 1200w |

|---|---|---|---|

| Ceramic Chips | 4PCS | Material | Alumium |

| Weight | 3kg | Application | Ultrasonic Welding |

| Capacitance | 11000~12000PF |

35kHZ Ultrasonic Welding Transducer with Titanium Booster with Closed Housing

| Frequency | 35 khz |

| Output power | 1200 watt |

| Joint bolt | M8*1.25 |

| Ceramic disc Diameter | 25 mm |

| Quantity of Ceramic discs | 4 pcs |

| Capacitance | 4nF |

| Amplitude | 10um |

| Application | welding machine |

Ultrasonic transducers are piezoelectric ceramics that resonate at ultrasonic frequencies and convert electrical signals into mechanical vibrations by the piezoelectric effect of the material. When the transducer is used as a transmitter, the electrical oscillating signal sent from the excitation source will cause a change in the electric or magnetic field in the electrical energy storage element of the transducer, which changes the mechanical vibration system of the transducer through some effort. A driving force is generated to cause it to vibrate, thereby propelling themedium in contact with the mechanical vibration system of the transducer to vibrate and radiate sound waves into the medium.

When an AC voltage is applied, piezo elements begin to oscillate. The extremely fast response in the microsecond range and below allow for ultrasound generation with frequencies of up to 20 MHz.

Ultrasonic applications can be classified in sensor applications and power ultrasound where the energy densities are higher and frequencies range from 20 to 800 kHz.

Power ultrasound can be used in medical applications, e.g. to crush kidney stones and for removing dental plaque, and industrial processes, such as cleaning and welding or bonding.

Advantages:

1. Heat resistance: It is made of high quality materials, has good heat resistance, low resonance impedance and low heat generation.

2. Strong structure: It is fastened with high quality standard steel bolts and has high reliability.

3. Electrical parameters: unique production process, digital equipment processing and assembly, high parameter performance and good consistency.

▏Warranty one year for transducer.

▏You can cantact us for technical inquiry any time.

▏We supply OEM service for oversea customer, also will keep Confidentiality for our customers.

▏Shipment by FED-EX/DHL

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!