loading

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-5020-4D |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 2000w |

|---|---|---|---|

| Ceramic Chips | 4PCS | Material | Alumium |

| Weight | 4kg | Application | Ultrasonic Welding |

| Capacitance | 11000~12000PF | Connect Screw | M8*1.5 |

20khz 2000w High Power Ultrasonic Welding Transducer for Welding Machine

What is ultrasonic transducer

Ultrasonic transducers are piezoelectric ceramics that resonate at ultrasonic frequencies and convert electrical signals into mechanical vibrations by the piezoelectric effect of the material. When the transducer is used as a transmitter, the electrical oscillating signal sent from the excitation source will cause a change in the electric or magnetic field in the electrical energy storage element of the transducer, which changes the mechanical vibration system of the transducer through some effect. A driving force is generated to cause it to vibrate, thereby propelling the medium in contact with the mechanical vibration system of the transducer to vibrate and radiate sound waves into the medium.

Advantage

1. The piezoelectric ceramic chip adopts imported parts, and can give a strong and stable output.

2. High efficiency, high mechanical quality factor, obtaining high electric-acoustic conversion efficiency work at the resonance frequency points.

3. Large amplitude: optimization design by computer , vibration speed ratio is high .

4. Large power,Under the action of prestressed screw, the energy of the piezoelectric ceramic to get maximum play;

5. Good heat resistance, small harmonic impedance, low calorific value, using temperature range is wide.

Ultrasonic welding transducers generate high-frequency vibrations of tens of thousands of times per second through the transducer at the vibrating head, generating local high temperatures, and melting the plastics in the weld zone for welding purposes. The ultrasonic welding transducer generally adopts a bolt-clamped longitudinal array structure, which is connected with the fixing fixture and the gathering head to form a plastic welding vibration system.

The ultrasonic welding transducer has the same starting principle as the cleaning transducer, but it has a higher power consumption. It usually cooperates with a plastic welding vibration system composed of a concentrating horn and a working head to complete ultrasonic welding of plastics, metals and the like.

Ultrasonic welding transducer features:

1. The resonance impedance is low.

2. The mechanical Q value is high.

3. Electroacoustic conversion efficiency is high.

4. Low calorific value.

5. Large amplitude and high vibration speed.

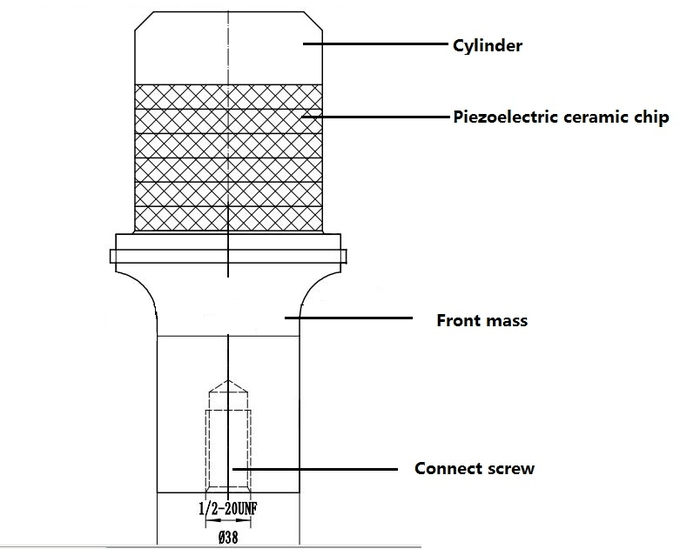

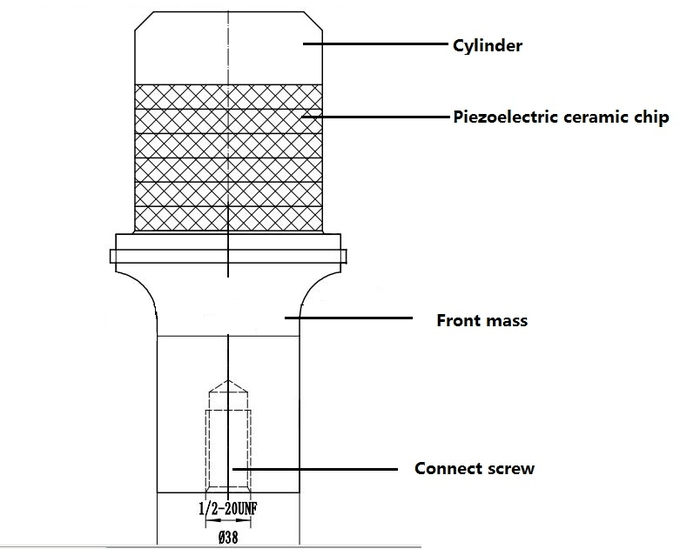

It generally adopts a horn type composite array structure (which belongs to the Langewen vibrator structure), and is composed of front and rear metal cover plates, piezoelectric ceramic wafers, prestressed screws, electrode sheets, and insulating sleeves.

Specification:

Material: Aluminium and steel alloy

Working life: 10years

Features:

1. It is made of piezoelectric ceramic material, which has high conversion efficiency and can be mass-produced.

2. The size and shape of the Ultrasonic Transducer for Welding are specially designed to match the welder completely.

3. The resonance impedance is small, the heat generation is small, the use temperature range is wide, and the reliability is high.

4. Its output is stable and not easy to crack.

5. The transducer has good electromechanical conversion efficiency under high power and high amplitude conditions.

6. Frequency and static capacitance are consistent.

| Item | Parameter |

| Frequency | 14.7~14.9Khz |

| Power | 2000W |

| Impedance | 15 |

| Capatance | 12500~14000pf |

| Frequency | 20Khz | Power | 2000w |

|---|---|---|---|

| Ceramic Chips | 4PCS | Material | Alumium |

| Weight | 4kg | Application | Ultrasonic Welding |

| Capacitance | 11000~12000PF | Connect Screw | M8*1.5 |

20khz 2000w High Power Ultrasonic Welding Transducer for Welding Machine

What is ultrasonic transducer

Ultrasonic transducers are piezoelectric ceramics that resonate at ultrasonic frequencies and convert electrical signals into mechanical vibrations by the piezoelectric effect of the material. When the transducer is used as a transmitter, the electrical oscillating signal sent from the excitation source will cause a change in the electric or magnetic field in the electrical energy storage element of the transducer, which changes the mechanical vibration system of the transducer through some effect. A driving force is generated to cause it to vibrate, thereby propelling the medium in contact with the mechanical vibration system of the transducer to vibrate and radiate sound waves into the medium.

Advantage

1. The piezoelectric ceramic chip adopts imported parts, and can give a strong and stable output.

2. High efficiency, high mechanical quality factor, obtaining high electric-acoustic conversion efficiency work at the resonance frequency points.

3. Large amplitude: optimization design by computer , vibration speed ratio is high .

4. Large power,Under the action of prestressed screw, the energy of the piezoelectric ceramic to get maximum play;

5. Good heat resistance, small harmonic impedance, low calorific value, using temperature range is wide.

Ultrasonic welding transducers generate high-frequency vibrations of tens of thousands of times per second through the transducer at the vibrating head, generating local high temperatures, and melting the plastics in the weld zone for welding purposes. The ultrasonic welding transducer generally adopts a bolt-clamped longitudinal array structure, which is connected with the fixing fixture and the gathering head to form a plastic welding vibration system.

The ultrasonic welding transducer has the same starting principle as the cleaning transducer, but it has a higher power consumption. It usually cooperates with a plastic welding vibration system composed of a concentrating horn and a working head to complete ultrasonic welding of plastics, metals and the like.

Ultrasonic welding transducer features:

1. The resonance impedance is low.

2. The mechanical Q value is high.

3. Electroacoustic conversion efficiency is high.

4. Low calorific value.

5. Large amplitude and high vibration speed.

It generally adopts a horn type composite array structure (which belongs to the Langewen vibrator structure), and is composed of front and rear metal cover plates, piezoelectric ceramic wafers, prestressed screws, electrode sheets, and insulating sleeves.

Specification:

Material: Aluminium and steel alloy

Working life: 10years

Features:

1. It is made of piezoelectric ceramic material, which has high conversion efficiency and can be mass-produced.

2. The size and shape of the Ultrasonic Transducer for Welding are specially designed to match the welder completely.

3. The resonance impedance is small, the heat generation is small, the use temperature range is wide, and the reliability is high.

4. Its output is stable and not easy to crack.

5. The transducer has good electromechanical conversion efficiency under high power and high amplitude conditions.

6. Frequency and static capacitance are consistent.

| Item | Parameter |

| Frequency | 14.7~14.9Khz |

| Power | 2000W |

| Impedance | 15 |

| Capatance | 12500~14000pf |

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!