loading

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-W15 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T, |

| Supply Ability | 200PCS/MONTH |

| Frequency | 15Khz | Power | 2600w |

|---|---|---|---|

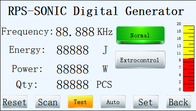

| Generator | Digital | Horn Material | Steel,titanium,alumium |

| Horn Size | Customized | Application | Ultrasonic Welding |

| Weight | 100kg |

15Kkz Digital Ultrasonic Plastic Welding Machine for PP welding

Parameter

| Frequency | Power | Working distance | Input voltage | Air pressure | System language |

| 15Khz | 2500W/3000W/4000W | 75mm/100mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 20Khz | 2000W/3000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 30Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 35Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 40Khz | 800W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

What is an ultrasonic welder?

Ultrasonic welding (USW) is a solid-state welding process that produces a weld by local application of high-frequency vibratory energy while the work pieces are held together under pressure. 5. A sound metallurgical bond is produced without melting the base material.

How does ultrasonic welding machine work?

The vibrations, produced by a welding sonotrode or horn, as it is generally known, are used to soften or melt the thermoplastic material at the joint line. The components to be joined are held together under pressure and subjected to vibrations, usually at a frequency of 20 or 40 kHz.

Where is ultrasonic welding used?

Ultrasonic welding is used in almost all major industries like automotive, electronic and appliances, medical, packaging etc. A limitation of ultrasonic welding is that with current technology, large joints cannot be welded in a single operation. In addition, specifically designed joint details are required.

Sonic welding

The electronic energy is converted into mechanical energy by ultrasonic vibration, and then the energy is transferred to the contact surface of the plastic workpiece by the welding head (HORN), which causes intense friction between molecules and promotes the instantaneous melting and integration of the product. The processing speed is fast and clean. , Beautiful and economical.

Welding scope: toy industry, stationery industry, home appliance industry, electronics industry, food industry, communication industry, transportation industry, aerospace, etc.

Examples of ultrasonic welding:

Daily necessities industry: powder box, makeup mirror, hair comb, lock ring, thermos cup, sealed container, seasoning bottle, water pipe joint, handle,

Bottle caps, food containers, car lampshades, car water tanks... etc.

Toy industry: all kinds of ball toys, stationery, water guns, plastic gifts, musical toys, and all kinds of plastic toys...etc.

Electrical industry: electronic clocks, steam irons, vacuum cleaners, telephones, computer keyboards, electric fans, batteries... etc.

Automobile manufacturing industry: car lights, rear mirrors, interiors, bumpers, various plastic products...etc.

Electronics industry: Mainly produces many plastic-related products such as power supplies, adapters, chargers, mobile phone casings, etc. The electronics industry is the industry that uses the most ultrasonic plastic welders.

Principle of Rotary Welding

It is designed for plastic circular thermoplastic products. The heat generated by the friction of the plastic workpieces causes the contact surface of the plastic workpieces to melt, and then the external pressure drives the upper and lower workpieces to solidify into one body and become a permanent combination.

Examples of rotary melting: RO filter, freezer cup, vacuum flask, vase, carburetor, shower head, thermos air bladder, Vaner Street, etc.

Service and shipment

Warranty one year for transducer.

You can contact us for technical inquiry any time.

We supply OEM service for oversea customer, also will keep Confidentiality for our customers.

We supply customized products service for small quantity also.

Shipment by FED-EX /DHL/UPS/TNT

| Frequency | 15Khz | Power | 2600w |

|---|---|---|---|

| Generator | Digital | Horn Material | Steel,titanium,alumium |

| Horn Size | Customized | Application | Ultrasonic Welding |

| Weight | 100kg |

15Kkz Digital Ultrasonic Plastic Welding Machine for PP welding

Parameter

| Frequency | Power | Working distance | Input voltage | Air pressure | System language |

| 15Khz | 2500W/3000W/4000W | 75mm/100mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 20Khz | 2000W/3000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 30Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 35Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 40Khz | 800W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

What is an ultrasonic welder?

Ultrasonic welding (USW) is a solid-state welding process that produces a weld by local application of high-frequency vibratory energy while the work pieces are held together under pressure. 5. A sound metallurgical bond is produced without melting the base material.

How does ultrasonic welding machine work?

The vibrations, produced by a welding sonotrode or horn, as it is generally known, are used to soften or melt the thermoplastic material at the joint line. The components to be joined are held together under pressure and subjected to vibrations, usually at a frequency of 20 or 40 kHz.

Where is ultrasonic welding used?

Ultrasonic welding is used in almost all major industries like automotive, electronic and appliances, medical, packaging etc. A limitation of ultrasonic welding is that with current technology, large joints cannot be welded in a single operation. In addition, specifically designed joint details are required.

Sonic welding

The electronic energy is converted into mechanical energy by ultrasonic vibration, and then the energy is transferred to the contact surface of the plastic workpiece by the welding head (HORN), which causes intense friction between molecules and promotes the instantaneous melting and integration of the product. The processing speed is fast and clean. , Beautiful and economical.

Welding scope: toy industry, stationery industry, home appliance industry, electronics industry, food industry, communication industry, transportation industry, aerospace, etc.

Examples of ultrasonic welding:

Daily necessities industry: powder box, makeup mirror, hair comb, lock ring, thermos cup, sealed container, seasoning bottle, water pipe joint, handle,

Bottle caps, food containers, car lampshades, car water tanks... etc.

Toy industry: all kinds of ball toys, stationery, water guns, plastic gifts, musical toys, and all kinds of plastic toys...etc.

Electrical industry: electronic clocks, steam irons, vacuum cleaners, telephones, computer keyboards, electric fans, batteries... etc.

Automobile manufacturing industry: car lights, rear mirrors, interiors, bumpers, various plastic products...etc.

Electronics industry: Mainly produces many plastic-related products such as power supplies, adapters, chargers, mobile phone casings, etc. The electronics industry is the industry that uses the most ultrasonic plastic welders.

Principle of Rotary Welding

It is designed for plastic circular thermoplastic products. The heat generated by the friction of the plastic workpieces causes the contact surface of the plastic workpieces to melt, and then the external pressure drives the upper and lower workpieces to solidify into one body and become a permanent combination.

Examples of rotary melting: RO filter, freezer cup, vacuum flask, vase, carburetor, shower head, thermos air bladder, Vaner Street, etc.

Service and shipment

Warranty one year for transducer.

You can contact us for technical inquiry any time.

We supply OEM service for oversea customer, also will keep Confidentiality for our customers.

We supply customized products service for small quantity also.

Shipment by FED-EX /DHL/UPS/TNT

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!