loading

| Availability: | |

|---|---|

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-W20 |

| Minimum Order Quantity | 1pcs |

| Price | Negotiable |

| Packaging Details | Wooden |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

20Khz 2000w Ultrasonic Welding Machine For PP/PVC/PE Welding Plastic Branson

Parameter

| Frequency | Power | Working distance | Input voltage | Air pressure | System language |

| 15Khz | 2500W/3000W/4000W | 75mm/100mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 20Khz | 2000W/3000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 30Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 35Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 40Khz | 800W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

Description

Ultrasonic welding uses ultrasonic energy at high frequencies (20–40 kHz) to produce low amplitude (1–25 μm) mechanical vibrations. The vibrations generate heat at the joint interface of the parts being welded, resulting in melting of the thermoplastic materials and weld formation after cooling.

Ultrasonic welding remains one of the fastest and most cost effective techniques for welding smaller thermoplastic parts. Using ultrasonic welding, one part is held stationary in a holding fixture while the other part is vibrated acoustically against it under pressure, creating frictional heat at their joining surfaces. With over twenty-ten years of experience in ultrasonic welding processes, our tooling engineers possess unmatched skill and experience to develop even the most complex ultrasonic tooling and part holding fixtures.

RPS-SONIC provides multiple welding modes (Weld by time, energy, distance, position, peak power and ground detect) and comes in various frequencies (15, 20, 30, 35, 40, 50 kHz) which make it flexible and reliable to be used for different types of applications in different industries. Dual pressure increases clamp force to improve melt during the weld cycle, or to provide tighter assembly during the hold cycle.

Welding principle

The electronic energy is converted into mechanical energy by ultrasonic vibration, and then the energy is transmitted to the contact surface of the plastic bow and arrow by the welding head (HORN), so that the principle of intense friction and heat generation occurs between the molecules, and the product is instantly melted and combined into one. Processing is fast, clean, beautiful and economical.

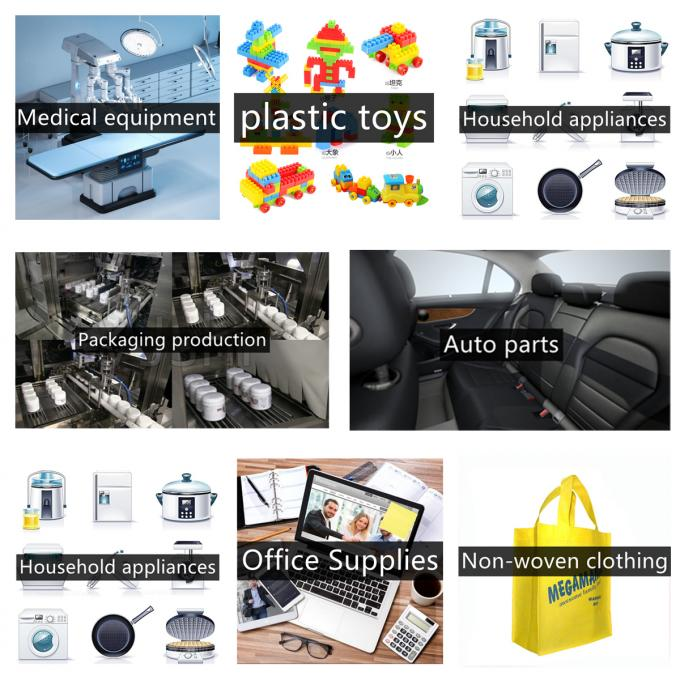

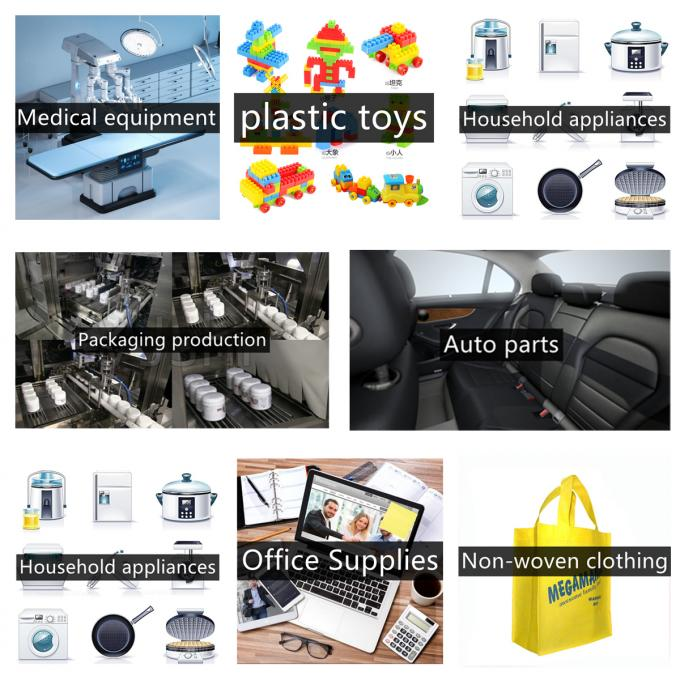

Welding range: toy industry, stationery industry, home appliance industry, electronics industry, food industry, communication industry, transportation industry, aerospace and so on.

Ultrasonic welding example:

Daily necessities industry: powder box, cosmetic mirror, hair comb, lock ring, thermos cup, sealed container, seasoning bottle, water pipe joint, handle,

Bottle caps, food containers, car lamp shades, car water tanks...etc.

Toy industry: all kinds of ball toys, stationery, water guns, plastic gifts, music toys, and all kinds of plastic toys...etc.

Electrical appliance industry: electronic clocks, steam irons, vacuum cleaners, telephones, computer keyboards, electric fans, batteries, etc.

Automobile manufacturing: headlights, rear mirrors, interiors, bumpers, various plastic products...etc.

The principle of rotary welding is designed for plastic round thermoplastic products. The heat generated by the mutual friction of the plastic workpieces melts the contact surface of the plastic workpieces, and then relies on external pressure to drive the upper and lower workpieces to solidify into one, becoming permanent.

Examples of rotary melting: RO filter, freezer cup, thermos cup, vase, carburetor, shower head, thermos air bladder, etc.

The hot plate welding principle uses the template to heat it to the required temperature, and then place it in the middle of the joint surface between the plastic workpiece and the workpiece, so that the heat is concentrated on the two joint surfaces. External pressure causes the workpieces to become one and become a function of solid durability. It can handle welded objects, and the products with high hardness, complex shape and huge volume can be solved.

Examples of hot melt: car lights, outdoor refrigerators, door panels, air pumps, water storage tanks, vacuum cleaners, hole balls, CD boxes, washing machine gimbal, rhythmic dance pedals, etc.

20Khz 2000w Ultrasonic Welding Machine For PP/PVC/PE Welding Plastic Branson

Parameter

| Frequency | Power | Working distance | Input voltage | Air pressure | System language |

| 15Khz | 2500W/3000W/4000W | 75mm/100mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 20Khz | 2000W/3000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 30Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 35Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 40Khz | 800W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

Description

Ultrasonic welding uses ultrasonic energy at high frequencies (20–40 kHz) to produce low amplitude (1–25 μm) mechanical vibrations. The vibrations generate heat at the joint interface of the parts being welded, resulting in melting of the thermoplastic materials and weld formation after cooling.

Ultrasonic welding remains one of the fastest and most cost effective techniques for welding smaller thermoplastic parts. Using ultrasonic welding, one part is held stationary in a holding fixture while the other part is vibrated acoustically against it under pressure, creating frictional heat at their joining surfaces. With over twenty-ten years of experience in ultrasonic welding processes, our tooling engineers possess unmatched skill and experience to develop even the most complex ultrasonic tooling and part holding fixtures.

RPS-SONIC provides multiple welding modes (Weld by time, energy, distance, position, peak power and ground detect) and comes in various frequencies (15, 20, 30, 35, 40, 50 kHz) which make it flexible and reliable to be used for different types of applications in different industries. Dual pressure increases clamp force to improve melt during the weld cycle, or to provide tighter assembly during the hold cycle.

Welding principle

The electronic energy is converted into mechanical energy by ultrasonic vibration, and then the energy is transmitted to the contact surface of the plastic bow and arrow by the welding head (HORN), so that the principle of intense friction and heat generation occurs between the molecules, and the product is instantly melted and combined into one. Processing is fast, clean, beautiful and economical.

Welding range: toy industry, stationery industry, home appliance industry, electronics industry, food industry, communication industry, transportation industry, aerospace and so on.

Ultrasonic welding example:

Daily necessities industry: powder box, cosmetic mirror, hair comb, lock ring, thermos cup, sealed container, seasoning bottle, water pipe joint, handle,

Bottle caps, food containers, car lamp shades, car water tanks...etc.

Toy industry: all kinds of ball toys, stationery, water guns, plastic gifts, music toys, and all kinds of plastic toys...etc.

Electrical appliance industry: electronic clocks, steam irons, vacuum cleaners, telephones, computer keyboards, electric fans, batteries, etc.

Automobile manufacturing: headlights, rear mirrors, interiors, bumpers, various plastic products...etc.

The principle of rotary welding is designed for plastic round thermoplastic products. The heat generated by the mutual friction of the plastic workpieces melts the contact surface of the plastic workpieces, and then relies on external pressure to drive the upper and lower workpieces to solidify into one, becoming permanent.

Examples of rotary melting: RO filter, freezer cup, thermos cup, vase, carburetor, shower head, thermos air bladder, etc.

The hot plate welding principle uses the template to heat it to the required temperature, and then place it in the middle of the joint surface between the plastic workpiece and the workpiece, so that the heat is concentrated on the two joint surfaces. External pressure causes the workpieces to become one and become a function of solid durability. It can handle welded objects, and the products with high hardness, complex shape and huge volume can be solved.

Examples of hot melt: car lights, outdoor refrigerators, door panels, air pumps, water storage tanks, vacuum cleaners, hole balls, CD boxes, washing machine gimbal, rhythmic dance pedals, etc.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!