loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-AT50 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 50Khz | Power | 10~100w |

|---|---|---|---|

| Flow Rate | <20ml/min | Generator | 2000E/2000C |

| Solution Utilization | 98% | Weight | 10kg |

| High Light | Automized Ultrasonic Spraying Nozzle Industrial,100w Ultrasonic Spraying Nozzle,50Khz Scattering Ultrasonic Spraying Nozzle | ||

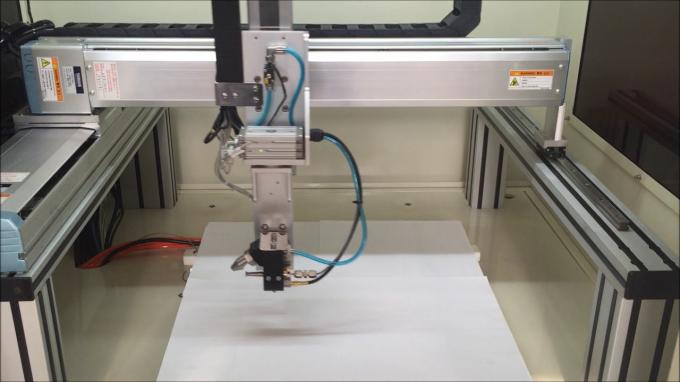

50Khz 100w Industrial Atomizer Ultrasonic Scattering Type Atomized Spraying Nozzle

Paramater

| Item | Parameter |

| Frequency | 50Khz |

| Power | 10~100w |

| FLOW RATE (ml/min) | 0~20ml/min |

| Spray width | 2~200mm |

| Solution utilization | above 98% |

Description

Ultrasonic spray (atomization) is the use of ultrasonic energy to disperse water or liquid to form tiny particles of several microns to more than 100 microns, which are used for humidifying air, liquid granulation, mixing, promoting chemical reactions, spraying, etc. Purpose.

Ultrasonic sprayer equipment, the power source adopts high-power ultrasonic transducer, and the whole machine is composed of ultrasonic transducer, horn, atomizing head, and special ultrasonic generator. The transducer drives the atomizing head to vibrate at high frequency, and applies ultrasonic force to water or other liquids to break up the flowing liquid into fine particles and spray them into the air, so as to achieve the purpose of spraying (atomization). With its unique gentle spraying characteristics, the device greatly reduces back spraying, thereby reducing costs and pollution to the surrounding air. At the same time, this new technology also expands more application fields, such as when spraying at low flow rates is required. ideal. In addition, for substrate spraying, atomizing humidification, spray drying, web spraying and other industrial and research and development applications, the sprayer equipment will also produce better results than other technologies.

The nebulizer equipment launched by RPS-SONIC, the power source adopts high-power ultrasonic transducer, and the whole machine is composed of ultrasonic transducer, horn, atomizing head, and special ultrasonic generator. The transducer drives the atomizing head to vibrate at high frequency, and applies ultrasonic force to water or other liquids to break up the flowing liquid into fine particles and spray them into the air, so as to achieve the purpose of spraying (atomization). With its unique gentle spraying characteristics, the device greatly reduces back spraying, thereby reducing costs and pollution to the surrounding air. At the same time, this new technology also expands more application fields, such as when spraying at low flow rates is required. ideal. In addition, for substrate spraying, atomizing humidification, spray drying, web spraying and other industrial and research and development applications, the sprayer equipment will also produce better results than other technologies.

Advantages of sprayer equipment

1. For precise spray applications, the spray shape is very easy to manipulate and form.

2. It can reduce waste and air pollution caused by back spraying, save energy and protect the environment.

3. Made of high-performance titanium alloy and stainless steel.

4. No pressure, no noise, no nozzle wear and clogging problems.

5. Low energy consumption and high atomization efficiency.

6. There is no limit to the medium, even sewage, chemical liquid, oil mucus can be atomized.

7. The amount of atomization can be adjusted at will, which is suitable for application in the industrial field. Through the combination, the amount of atomization can meet any requirements of the user.

| Frequency | 50Khz | Power | 10~100w |

|---|---|---|---|

| Flow Rate | <20ml/min | Generator | 2000E/2000C |

| Solution Utilization | 98% | Weight | 10kg |

| High Light | Automized Ultrasonic Spraying Nozzle Industrial,100w Ultrasonic Spraying Nozzle,50Khz Scattering Ultrasonic Spraying Nozzle | ||

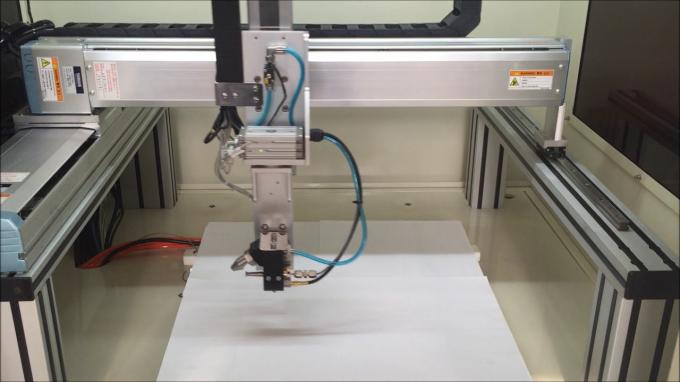

50Khz 100w Industrial Atomizer Ultrasonic Scattering Type Atomized Spraying Nozzle

Paramater

| Item | Parameter |

| Frequency | 50Khz |

| Power | 10~100w |

| FLOW RATE (ml/min) | 0~20ml/min |

| Spray width | 2~200mm |

| Solution utilization | above 98% |

Description

Ultrasonic spray (atomization) is the use of ultrasonic energy to disperse water or liquid to form tiny particles of several microns to more than 100 microns, which are used for humidifying air, liquid granulation, mixing, promoting chemical reactions, spraying, etc. Purpose.

Ultrasonic sprayer equipment, the power source adopts high-power ultrasonic transducer, and the whole machine is composed of ultrasonic transducer, horn, atomizing head, and special ultrasonic generator. The transducer drives the atomizing head to vibrate at high frequency, and applies ultrasonic force to water or other liquids to break up the flowing liquid into fine particles and spray them into the air, so as to achieve the purpose of spraying (atomization). With its unique gentle spraying characteristics, the device greatly reduces back spraying, thereby reducing costs and pollution to the surrounding air. At the same time, this new technology also expands more application fields, such as when spraying at low flow rates is required. ideal. In addition, for substrate spraying, atomizing humidification, spray drying, web spraying and other industrial and research and development applications, the sprayer equipment will also produce better results than other technologies.

The nebulizer equipment launched by RPS-SONIC, the power source adopts high-power ultrasonic transducer, and the whole machine is composed of ultrasonic transducer, horn, atomizing head, and special ultrasonic generator. The transducer drives the atomizing head to vibrate at high frequency, and applies ultrasonic force to water or other liquids to break up the flowing liquid into fine particles and spray them into the air, so as to achieve the purpose of spraying (atomization). With its unique gentle spraying characteristics, the device greatly reduces back spraying, thereby reducing costs and pollution to the surrounding air. At the same time, this new technology also expands more application fields, such as when spraying at low flow rates is required. ideal. In addition, for substrate spraying, atomizing humidification, spray drying, web spraying and other industrial and research and development applications, the sprayer equipment will also produce better results than other technologies.

Advantages of sprayer equipment

1. For precise spray applications, the spray shape is very easy to manipulate and form.

2. It can reduce waste and air pollution caused by back spraying, save energy and protect the environment.

3. Made of high-performance titanium alloy and stainless steel.

4. No pressure, no noise, no nozzle wear and clogging problems.

5. Low energy consumption and high atomization efficiency.

6. There is no limit to the medium, even sewage, chemical liquid, oil mucus can be atomized.

7. The amount of atomization can be adjusted at will, which is suitable for application in the industrial field. Through the combination, the amount of atomization can meet any requirements of the user.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!