loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-W20 |

| Minimum Order Quantity | 1pcs |

| Price | Negotiable |

| Packaging Details | Wooden |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 30 sets/MONTH |

| Frequency | 20Khz | Power | 2000w |

|---|---|---|---|

| Generator | 2000C Digital | Horn Material | Steel/Aluminum/Titanium Alloy |

| Power Cabinet | Spray | Type | Automatic |

| High Light | 20K Frequency Ultrasonic Welding Equipment,Ultrasonic Welding Machine PLC Control,Ultrasonic Welding Equipment PLC Control | ||

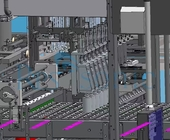

20Khz Ultrasonic Welding Machine For Plastic Cup Welding With Digital PLC Control

20Khz ultrasonic welding machine for plastic cup welding

Parameter

| Frequency | Power | Working distance | Input voltage | Air pressure | System language |

| 15Khz | 2500W/3000W/4000W | 75mm/100mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 20Khz | 2000W/3000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 30Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 35Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 40Khz | 800W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

Description

Ultrasonic welding machine is ultrasonic generator, transducer system and program control. The power supply takes a nominal 220v line voltage and converts it to a high voltage, high frequency signal. It also contains ultrasonic transducers and parameter controls to achieve the desired welding results. Pneumatic or electric servo-operated actuators are available as stand-alone benchtop units or integrated into automated systems to move ultrasonic tools towards the parts to be joined. It applies the required pressure to the material to help create the welding conditions.

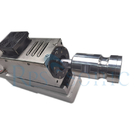

Ultrasonic vibration unit. It transmits vibrational energy to the surface of the product through direct contact with the part. Ultrasonic vibration units generally consist of three parts: an ultrasonic transducer, which contains a piezoceramic crystal that oscillates at the frequency of an applied power signal. When these crystals oscillate, they physically expand and contract, creating a measurable mechanical movement (called peak-to-peak amplitude) on the output side of the transducer.

The second part is the booster or horn, with a connecting ring in its middle part, which has two functions: it serves as a fixed mounting point for the vibratory system, and it also serves to amplify or reduce the output movement produced in the transducer.

The third and final component of the vibration system is the sonotrode, which acts as an ultrasonic die, which will contact the parts to be joined. Ultrasonic molds will be designed to match the outer contour of the plastic product, or a sealing contour can be added to its contact surface in film/textile applications. For each application, the horn is designed to combine with the transducer assembly to achieve the optimum level of amplitude output for the most efficient ultrasonic welding possible.

Ultrasonic plastic welding is usually carried out in five steps

1. Surface preparation, surface preparation is very important, because most of the molded plastic products have a layer of release agent or dirt on the surface, which must be cleaned to make the welding go smoothly.

2. Heating. There are many heating methods, which are also the main basis for distinguishing different welding methods.

3. Pressurization. The methods of applying pressure include: manual pressurization, press pressurization, automatic fixture pressurization, etc. Embossing is usually done at the same time as welding.

4. Diffusion or welding, once the interface between liquid and liquid is established, the diffusion will proceed immediately; for crystalline or semi-crystalline materials, the diffusion is almost instantaneous; for non-crystalline materials, if the heating temperature is slightly higher than the melting point, the diffusion time will be shorter very long.

5. Cooling. The last step is to cool the weldment and solidify the joint. Welding pressure must be maintained until the joint has not achieved sufficient strength and stiffness to support the entire weldment.

| Frequency | 20Khz | Power | 2000w |

|---|---|---|---|

| Generator | 2000C Digital | Horn Material | Steel/Aluminum/Titanium Alloy |

| Power Cabinet | Spray | Type | Automatic |

| High Light | 20K Frequency Ultrasonic Welding Equipment,Ultrasonic Welding Machine PLC Control,Ultrasonic Welding Equipment PLC Control | ||

20Khz Ultrasonic Welding Machine For Plastic Cup Welding With Digital PLC Control

20Khz ultrasonic welding machine for plastic cup welding

Parameter

| Frequency | Power | Working distance | Input voltage | Air pressure | System language |

| 15Khz | 2500W/3000W/4000W | 75mm/100mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 20Khz | 2000W/3000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 30Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 35Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 40Khz | 800W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

Description

Ultrasonic welding machine is ultrasonic generator, transducer system and program control. The power supply takes a nominal 220v line voltage and converts it to a high voltage, high frequency signal. It also contains ultrasonic transducers and parameter controls to achieve the desired welding results. Pneumatic or electric servo-operated actuators are available as stand-alone benchtop units or integrated into automated systems to move ultrasonic tools towards the parts to be joined. It applies the required pressure to the material to help create the welding conditions.

Ultrasonic vibration unit. It transmits vibrational energy to the surface of the product through direct contact with the part. Ultrasonic vibration units generally consist of three parts: an ultrasonic transducer, which contains a piezoceramic crystal that oscillates at the frequency of an applied power signal. When these crystals oscillate, they physically expand and contract, creating a measurable mechanical movement (called peak-to-peak amplitude) on the output side of the transducer.

The second part is the booster or horn, with a connecting ring in its middle part, which has two functions: it serves as a fixed mounting point for the vibratory system, and it also serves to amplify or reduce the output movement produced in the transducer.

The third and final component of the vibration system is the sonotrode, which acts as an ultrasonic die, which will contact the parts to be joined. Ultrasonic molds will be designed to match the outer contour of the plastic product, or a sealing contour can be added to its contact surface in film/textile applications. For each application, the horn is designed to combine with the transducer assembly to achieve the optimum level of amplitude output for the most efficient ultrasonic welding possible.

Ultrasonic plastic welding is usually carried out in five steps

1. Surface preparation, surface preparation is very important, because most of the molded plastic products have a layer of release agent or dirt on the surface, which must be cleaned to make the welding go smoothly.

2. Heating. There are many heating methods, which are also the main basis for distinguishing different welding methods.

3. Pressurization. The methods of applying pressure include: manual pressurization, press pressurization, automatic fixture pressurization, etc. Embossing is usually done at the same time as welding.

4. Diffusion or welding, once the interface between liquid and liquid is established, the diffusion will proceed immediately; for crystalline or semi-crystalline materials, the diffusion is almost instantaneous; for non-crystalline materials, if the heating temperature is slightly higher than the melting point, the diffusion time will be shorter very long.

5. Cooling. The last step is to cool the weldment and solidify the joint. Welding pressure must be maintained until the joint has not achieved sufficient strength and stiffness to support the entire weldment.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!