loading

| Availability: | |

|---|---|

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-W35 |

| Minimum Order Quantity | 1set |

| Price | $8500/set |

| Packaging Details | carton box |

| Payment Terms | T/T |

| Supply Ability | 200pcs |

Parameter:

| Item | Parameter |

| Frequency | 20Khz |

| Power | 1000W |

| Ceramice chips | 4chips |

| Speed | 20m/min in max |

| Welding width | 15mm in max |

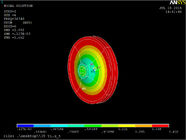

| Welding horn | 20Khz rotary horn |

| Welding type | Continues welding |

An ultrasonic pillow-making machine is a specialized industrial machine designed to produce pillows, cushions, or similar items using ultrasonic technology. It bonds and seals synthetic fabrics and fillings without the need for traditional stitching, making the process faster and more efficient while ensuring a clean, durable finish.

The principle of the ultrasonic lace machine is to generate high-frequency vibration waves through an ultrasonic generator. These vibration waves are amplified by the horn and tool head and act on thermoplastic synthetic fiber fabrics. Under the action of pressure, the flower wheel contacts the fabric and performs ultrasonic cutting and welding to form beautiful lace or perform welding.

Applications:

Home Textiles:

Producing pillows, cushions, and decorative items.

Medical Industry:

Creating sterile, hypoallergenic pillows for hospitals or medical settings.

Automotive:

Manufacturing headrests or cushions for car interiors.

Outdoor Gear:

Making waterproof or weather-resistant cushions for outdoor furniture or camping gear.

Efficiency:

Faster production compared to traditional sewing, with simultaneous cutting and sealing.

Seamless Finish:

Produces clean and aesthetic edges without visible stitches.

Durability:

Ultrasonic seams are strong and resistant to wear and tear.

Eco-Friendly:

Reduces waste by eliminating thread and adhesive usage.

Low Maintenance:

No needles or threads to replace, reducing downtime.

Parameter:

| Item | Parameter |

| Frequency | 20Khz |

| Power | 1000W |

| Ceramice chips | 4chips |

| Speed | 20m/min in max |

| Welding width | 15mm in max |

| Welding horn | 20Khz rotary horn |

| Welding type | Continues welding |

An ultrasonic pillow-making machine is a specialized industrial machine designed to produce pillows, cushions, or similar items using ultrasonic technology. It bonds and seals synthetic fabrics and fillings without the need for traditional stitching, making the process faster and more efficient while ensuring a clean, durable finish.

The principle of the ultrasonic lace machine is to generate high-frequency vibration waves through an ultrasonic generator. These vibration waves are amplified by the horn and tool head and act on thermoplastic synthetic fiber fabrics. Under the action of pressure, the flower wheel contacts the fabric and performs ultrasonic cutting and welding to form beautiful lace or perform welding.

Applications:

Home Textiles:

Producing pillows, cushions, and decorative items.

Medical Industry:

Creating sterile, hypoallergenic pillows for hospitals or medical settings.

Automotive:

Manufacturing headrests or cushions for car interiors.

Outdoor Gear:

Making waterproof or weather-resistant cushions for outdoor furniture or camping gear.

Efficiency:

Faster production compared to traditional sewing, with simultaneous cutting and sealing.

Seamless Finish:

Produces clean and aesthetic edges without visible stitches.

Durability:

Ultrasonic seams are strong and resistant to wear and tear.

Eco-Friendly:

Reduces waste by eliminating thread and adhesive usage.

Low Maintenance:

No needles or threads to replace, reducing downtime.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment